When you leave an order of PCBs, you should take items including PCB substrate material, solder mask, silkscreen, surface finish, board size and thickness, copper thickness, blind and buried vias, through-hole plating, SMT, panels, tolerances, etc. into consideration prior to the real fabrication of your circuit boards. Among those items, the selection of surface finish belongs to the first class as surface finish plays an extremely significant role in contributing to the reliability of electronic products. As copper layer on PCBs can be easily oxidized, the generated copper oxidation layer will seriously reduce soldering quality, which will decrease reliability and validity of the end products. Surface finish is conductive to prevent pads from oxidation and guarantee excellent solderability and electric performance.

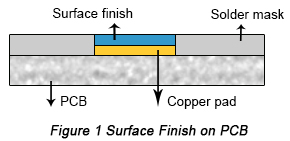

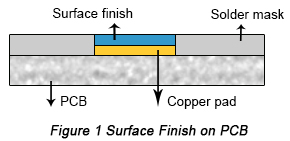

Surface finish, or surface coating, is the most important step in the process between PCB board manufacturing and circuit card assembly with two main functions, one of which is to preserve the exposed copper circuitry and the other of which is to provide solderable surface when soldering components to the PCB. As is shown in Figure 1, surface finish is located at the outermost layer of PCB and above copper, playing a role as a "coat" for copper.

Types of Surface Finish

Basically, there are two main types of surface finishes: metallic and organic. HASL, ENIG/ENEPIG, Immersion gold and Immersion Tin all belong to metallic surface finishes while OSP and Carbon ink belong to organic surface finish.

• HASL (Hot Air Solder Leveling)

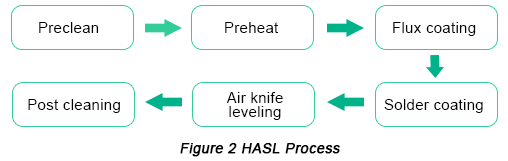

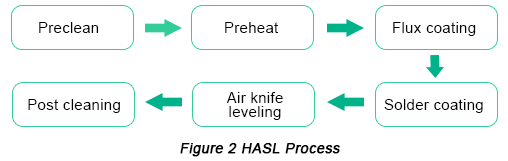

HASL is a conventional type of surface finish applied on PCBs. The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Extra solder is removed by passing the PCB between hot air knives. Usually, HASL follows the procedure like the description of Figure 2 below:

|

Pros of HASL Surface Finish

|

Cons of HASL Surface Finish

|

• Excellent wetting during component soldering;

• Copper corrosion avoided;

|

• Low planarity on vertical levelers leads HASL

unacceptable for fine pitch components;

• High thermal stress during process causes

defects into circuit board;

|

In order to conform to regulations concerning environment protection, HASL develops into two subcategories: lead HASL and lead-free HASL. The latter caters to regulations and laws of RoHS (restrictions of hazardous substances) first adopted by EU.

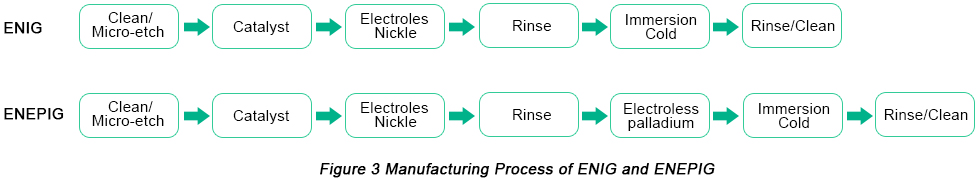

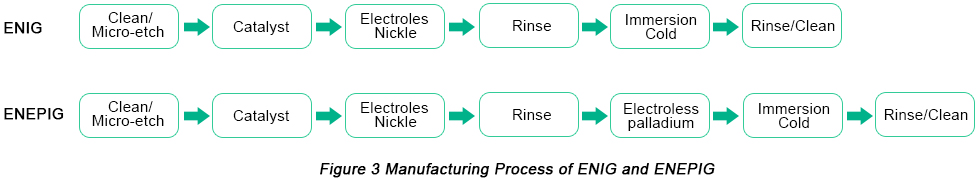

• ENIG and ENEPIG

ENIG, short for Electroless Nickel Immersion Gold, consists of electroless nickel plating covered with a thin layer of immersion gold, which protects the nickel from oxidation. ENEPIG, also known as Electroless Nickel Electroless Palladium Immersion Gold, differs from ENIG in that a layer of palladium is applied as a resistance layer to stop nickel from oxidation and diffusion to copper layer. Compared to other types of surface finishes, ENIG and ENEPIG provide the highest solderability for PCBs but the cost is much higher. The difference between manufacturing processes of ENIG and ENEPIG can be found in Figure 3 below.

The electroless nickel step is an auto-catalytic process that involves depositing nickel on the palladium-catalyzed copper surface. The reducing agent containing nickel ions must be replenished in order to provide proper concentration, temperature and acid degrees necessary to create a consistent coating. During the immersion gold step, the gold adheres to the nickel plated areas through molecular exchange, which will protect the nickel until the soldering process. The gold thickness needs to meet certain tolerances to ensure that the nickel maintains its solderability.

ENIG and ENEPIG have their own pros and cons respectively. For example, ENIG features flat surface, simple process mechanism and high temperature resistance while ENEPIG is capable of withstanding excellent multiple reflow cycles and features highly reliable wire bonding capability. Based on comparison between ENIG and ENEPIG, they can be applied in different applications for different purposes. ENIG is suitable for lead-free soldering, SMT (surface mounted technology), BGA (ball grid array) package etc. while ENEPIG is capable of meeting strict requirements of multiple types of packages including THT (through-hole technology), SMT, BGA, wire bonding, press fit etc.

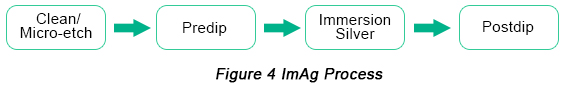

• ImAg (Immersion Silver)

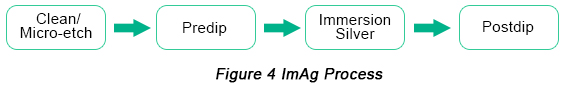

ImAg consists of thin immersion silver plating over the copper traces. Usually, ImAg follows the procedure below:

|

Pros of ImAg Surface Finish

|

Cons of ImAg Surface Finish

|

• Planar surface;

• Short, easy process cycle;

• Inexpensive;

• High conductivity;

• Good for fine pitch product;

• Copper/Tin solder joint;

• Reworkable;

• Not affect hole size

;

|

• Tarnish

;

• Silver migration;

• Planar micro voids;

• Creep corrosion;

|

ImAg is a good type of surface finish for soldering and testing. Creep corrosion is its major weakness.

• ImSn (Immersion Tin)

ImSn is mostly the same as ImAg except that tin is used in ImSn while silver is used in ImAg. In terms of the advantages of ImSn, it provides an extremely planar finish on the copper pads, making it very suitable for SMT applications. Besides, ImSn provides a surface that is easily detectable by common Automated Optical Inspection techniques.

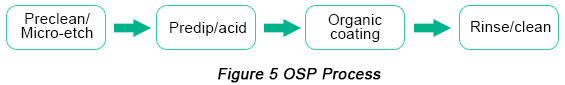

• OSP (Organic Solderability Preservatives)

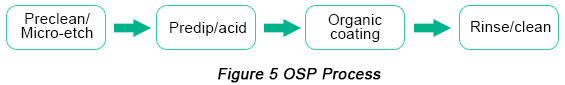

OSP is a type of surface finish with transparent organic material participated. It uses a water-based organic compound that selectively bonds to copper and protects the copper until soldering. Usually, OSP follows the process as the follows:

|

Pros of OSP Surface Finish

|

Cons of OSP Surface Finish

|

• Flat/planar;

• Short, easy process cycle

;

• Inexpensive;

•

Reworkable

;

• Not affect finished hole size;

• Copper/Tin solder joint;

|

• Multiple reflows

;

•

Limited shelf life

;

• Not conductive

;

• Difficult to inspect;

•

Limited thermal cycles

;

|

The above description fails to explain anything concerning OSP. You can refer to article things you barely know about OSP to get more details of OSP surface finish technology.

In summary, each type has its own advantages and disadvantages. You should select the best fit surface finish according to your electronic product’s utilization purposes, performance requirements, cost, corrosion resistance, ICT (in-circuit test), hole fill, etc. The more items taken into consideration during the selection, the more accurate your conclusion will be.

Comparing these types of surface finishes, generally speaking, in terms of COST, ImAg and OSP are the most inexpensive while ENIG is the most costly. In terms of CORROSION RESISTANCE, HASL and ImSn have the best corrosion resistance capability while ImAg has the worst. In terms of ICT, only OSP is the worst while others are just similarly good. In terms of HOLE FILL, HASL and ENIG are better than the other types.

Surface Finish Selection

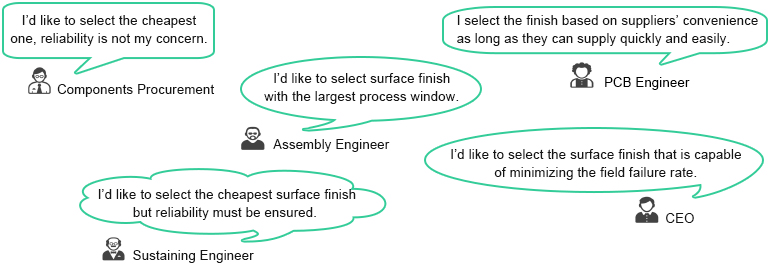

Surface finish selection on PCBs is the most important step for PCB fabrication since it directly influences process yields, rework numbers, field failure rate, test capability, scrap rate and cost. All the important considerations about assembly must be taken into surface finish selection in order to ensure the high quality and performance of end products.

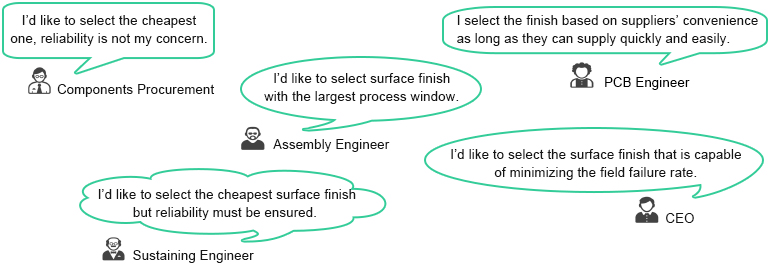

In PCB assembly process, people with different positions have different opinions on how to select surface finish, as shown in the picture below:

Apparently, people with different positions have different selection standards. No matter what type is selected, it only caters to the requirements and convenience of people with few considerations about the quality, performance and reliability of PCBs and PCB assembly.

Based on the introduction of each type of surface finish above, some attributes are the most important elements as the selection standard. The below table shows the attributes each type of surface finish HAS and DOESN NOT HAVE. Based on specific requirements and features of PCB products, you can follow this table to select the perfect surface finish option.

|

Items

|

HASL

|

ENIG

|

ENEPIG

|

ImAg

|

ImSn

|

OSP

|

|

Cost sensitive product

|

√

|

x

|

x

|

√

|

√

|

√

|

|

High volume required

|

x

|

x

|

x

|

√

|

√

|

√

|

|

Cosmetics of surface finish

|

√

|

x

|

√

|

x

|

√

|

√

|

|

Lead-free wave solder

|

√

|

√

|

√

|

√

|

x

|

x

|

|

Fine pitch components used

|

x

|

√

|

√

|

√

|

√

|

√

|

|

Requirement of wire bonding to surface finish

|

x

|

√

|

√

|

√

|

x

|

x

|

|

High yield ICT

|

√

|

√

|

√

|

√

|

√

|

x

|

|

Lead-free shock/drop

|

√

|

x

|

x

|

√

|

√

|

√

|

|

Possibilities of corrosion failure

|

√

|

√

|

√

|

x

|

√

|

√

|

All in all, as for the type of surface finish selection, an optimal type must be selected and numerous functions can be accomplished. Each type of surface finish has its own advantages and disadvantages. But don’t worry. There are some engineering tricks as the solutions to the problems caused by cons of surface finish. For example, as for the disadvantage that OSP has lower wetting force, some solutions are available such as changing board solderability plating or wave solder alloy, increasing top-side preheat etc. The key point is that all the possible elements must be considered in order to obtain ideal performance.

Nowadays, environment issues have become increasingly important in the electronic fields. In order to restrain the generated hazardous substances, RoHS is published by EU. RoHS, also known as Lead-Free, stands for Restriction of Hazardous Substances. RoHS, also known as Directive 2002/95/EC, originated in the European Union and restricts the use of six hazardous materials found in electrical and electronic products. All applicable products in the EU market after July 1, 2006 must pass RoHS compliance. RoHS impacts the entire electronics industry and many electrical products as well. So, surface finishes with lead-free solder will have more followers in the future.

PCBCart offers online price calculator for you to calculate PCBs with different surface finish. Click the below button to enter PCB quote page, you will see how PCB price varies with surface finish transformation by inputing different surface finish options.

Check Price Difference of PCBs with Different Surface Finish

Helpful Resources

• The Most Comprehensive Guidelines for Surface Finish Selection

• Comparison between ENIG and ENEPIG

• Things You Barely Know about OSP