Thin-film micro-strip circuits have been widely applied in microwave communications, electronic countermeasure (ECM), aerospace industry etc. When manufacturing thin-film ICs (Integrated Circuits), it is very important to apply deposited thin-film resistor material to fabricate high-accuracy and high-stability thin-film embedded resistors. Thin-film ICs call for stringent requirement on thin-film resistors:

a.Square resistance should be wide enough;

b.Temperature coefficient of resistance should be small;

c.Adhesive force with substrate should be strong enough;

d.Thin-film resistors should feature a stable and reliable performance;

e.Filming should be easy and convenient;

f.Should be capable of putting up with high-temperature processing, high power and relatively wide application range.

A Brief Introduction of Embedded PCB

As early as 1959, the first IC invented by Jack Kilby contained only two transistors and a resistor. Nowadays, multiple complex techniques are applied to combine tens of millions of transistors into one single PC chip. With electronic products stepping towards miniaturization and multifunction, a type of embedded passive component technology occurred to meet the increasingly higher demands. Ratio between passive parts and active parts is approximately 20:1, integrity has been gradually going up with the ratio rising. With so many passive components embedded in PCBs, the area of circuit board manufactured through SMT shrinks by 40% compared to board fabricated through embedded technology. The early beginning of 1980s saw the starting of embedded passive component technology that is usually achieved in a planar form. Based on passive component classification, embedded PCBs can be further classified into embedded resistor PCBs, embedded capacitor PCBs and embedded inductor PCBs. Resistors, capacitors and inductors can be nearly seen in all electronic systems, providing impedance and storing energy for the system. Among those embedded passive components, capacitors and resistors account for the majority, at least 80% of all altogether. Up to now, embedded passive components have been widely applied in numerous circuit fields such as filters, attenuators, baluns, Bluetooth, power amplifiers etc. Furthermore, some trends including high-speed and high-frequency development of digital signals, constantly decreasing of voltage of passive components, gradual strengthening of functions and gradual densification of signal transmissions call for participation of more low-capacitance bypass capacitors to eliminate electromagnetic coupling and signal crosstalk. Therefore, embedded capacitor PCB technology has attracted a wide range of attention by the industry.

Merits of Embedded Resistors

Advantages of embedded resistors mainly come in three aspects: electrical performance, PCB design and reliability.

• Electrical Advantages

a. It helps improve line impedance matching.

b. It leads to shorter signal paths and decreased series inductance.

c. It causes reduction of cross talk, noise and EMI (Electromagnetic Interference).

• PCB Design Advantages

a. It leads to active component density improvement and decreased form factors.

b. It calls for no requirement of vias, leading routing to improvement.

c. It results in simplified boards, shrinking size and/or densification.

• Improved Reliability

Below tables shows improved reliability of embedded resistors.

|

Items

|

Parameters

|

|

Low RTC

|

<50PPM |

|

Life testing

|

100,000 hours; <2% drift at 110°C |

|

Stable over wide frequencies

|

Tested beyond 40GHz |

|

Solder joints

|

NONE |

|

Testing stage |

Inner layer and bare board |

Factors Determining Performance of Thin Film

Up to now, thin-film resistor material covers a wide application range containing chromium material, tantalum material and titanium material. Compared with chromium thin-film resistors, tantalum thin-film resistors feature many excellent performances such as excellent chemical stability and corrosion resistance, high reliability, wide resistance range and high stability, which makes it an ideal thin-film resistor material with a broad application prospect.

Uniformity of resistor thin film refers to the situation in which how resistors fabricated on the substrate change as substrate position changes in vacuum cavity and how resistance modifies as the same substrate moves. Leading factors driving uniformity of thin film include: relative position between substrate and target material, deposition rate and vacuum degree. Tantalum nitride (TaN) film applicable to thin-film ICs features excellent uniformity both on the same substrate and between substrates from different positions. Moreover, resistance error between different batches maintains low with excellent uniformity. Currently there are two preparation methods available for TaN film preparation: physical vapor deposition and chemical vapor deposition. Stability and reliability, accuracy and uniformity of electrical resistivity play an important role in TaN film manufacturing. Resistance is modified mainly through laser or oxidation to ensure the accuracy of resistance. Both methods, however, feature some drawbacks that laser possibly damages resistance graphics with power withstand by resistor film whereas resistance modification through oxidation suffers from a low rate and bad reliability.

This article takes advantage of magnetron reactive sputtering to prepare TaN thin film and studies the influence of technical parameters such as uniform plate position on TaN thin film uniformity and performance, determining accurate controlled technology of resistance rate. Furthermore, it studies and analyzes deposition scanning rate and effects of flow ratio of N2 on TaN thin film and performance.

Performance Analysis on Thin Film

• Uniformity Analysis

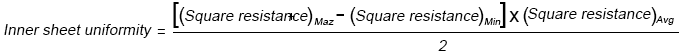

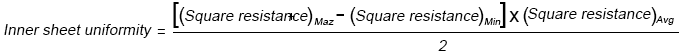

Under the condition of fixed scanning speed of 105cm/min and 10% of nitrogen flow ratio, uniformity is analyzed for TaN thin film. Inner sheet uniformity can be figured out through formula:  .

.

A resistance instrument is applied to measure resistance and each piece of base sheet has to sacrifice 60 points for measurement, here's the result:

|

Position

|

R□Max

|

R□Min

|

R□Avg

|

Uniformity

|

|

Ω•□-1

|

Ω•□-1

|

Ω•□-1

|

%

|

|

1

|

55.70

|

53.51

|

54.86

|

2.00

|

|

2

|

48.04

|

47.08

|

47.66

|

1.01

|

|

3

|

53.96

|

51.91

|

52.78

|

1.94

|

It indicates resistance distribution of TaN thin film on a base sheet whose size is 4inch. Accordingly, it can be summarized that base sheet with No.2 position features the best uniformity of inner sheet while base sheet close to plate edge or target material edge features relatively bad square resistance variation and inner sheet uniformity of target material close to target material edge is the worst. TaN thin film with bad uniformity leads to huge effect on high-accuracy network resistor manufacturing.

To defeat non-uniformity of thin film close to target material edge, a uniform plate can be installed to adjust deposited thin film because it is capable of selectively covering deposition area to control film uniformity.

• Deposition Scanning Speed Analysis

With the acceleration of scanning, square resistance of TaN thin film displays a trend of enlargement with linear improvement. The higher scanning speed is, the shorter the deposition time will be and so will the number of atoms on thin film. Film will be thinner as well. Three structures are available in the process of thin film generation: island-shape structure, net-shape structure and continuous structure. Properties of thin film are closely related with its structure and elements. When the film is relatively thin, the film comes in a structure of island. With the film becomes thick, the island structure transforms into net structure and continuous structure. When it comes to resistor thin film, however, three types of phase structures are available: conductive phase, semiconductor phase and insulation phase. In an island structure, conductive phase particles are scattered in thin film like shutter islands that are surrounded by insulation phase. Therefore, the film square resistance is relatively high. Net-shape structure, however, is actually a conductive network composed by the interconnection between conductive particles. Insulation phases are scattered inside the network with a low square resistance. Continuous structure is a type of continuously thin film composed of accumulating conductive particles densely, containing few insulation elements. As a result, thin film square resistance is shrinking.

• Nitrogen Flow Analysis

a. Influence of Nitrogen Flow on TaN Thin Film Square Resistance. With the improvement of nitrogen flow ratio, square resistance of TaN thin film gradually goes up. This law works dramatically especially when nitrogen flow rate increases from 15% to 20%. That's because the increasing of nitrogen partial pressure leads to the increasing of Ta cavities and conductive type of thin film will convert from electronic conduction to cavity conduction. As a result, square resistance will finally rise.

b. Influence of Nitrogen Flow Rate on TaN Thin Film Thickness. The increasing of nitrogen flow rate leads to gradual reduction of TaN thin film thickness, which is opposite to the change trend of square resistance. Film thickness is closely associated with mean free path of sputtered particles and sputtering rate of target material.

In a word, thin-film embedded resistors feature agreeable uniformity, leading to its successful applications in a wide range of industries. A great number of tests and experiments have been performed to demonstrate the reliability of thin-film embedded resistors. Therefore, it can be expected that thin-film embedded resistors can be highly relied in numerous electronic applications.

.

.