In the world of PCB, you may have heard both the terms blind via and buried via. What is blind via and buried via, and what do they mean to your project? To understand the answer, first, we need to know what vias are in reference to PCB.

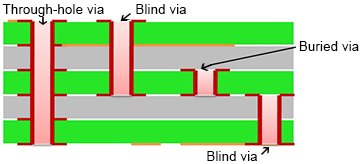

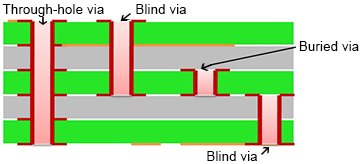

Vias are the copper-plated holes in the PCB that allows the layers to connect. The standard via is called a through-hole via, but there are several disadvantages to using through-hole vias in Surface Mount Technology (SMT). For this reason, we often use a blind via or buried via instead. A blind or buried via can be processed in a wide range of different measures, including plugged copper mask via, a plugged solder mask via, plated via or staggered via.

• What is Blind Via?

In a blind via, the via connects the external layer to one or more inner layers of the PCB and is responsible for the interconnection between that top layer and the inner layers.

• What is Buried Via?

In a buried via, only the inner layers of the board are connected by the via. It is "buried" inside the board and not visible from the outside.

Blind and buried vias are particularly advantageous in HDI board because they optimize the density of the boards without increasing board size or the number of board layers you require.

• What is Stacked Via and Microvia?

A stacked via is a way to further improve size and density considerations when manufacturing PCBs — factors that are extremely important with today's miniaturization and high-signal transmission speed requirements in many applications.

If you have blind vias with an aspect ratio greater than 1:1, or your drilling needs cover multiple layers, a stacked via can be the best way to get a reliable internal connection.

Stacked vias are laminated blind or buried vias, multiple vias inside a circuit board built together around the same center. Staggered vias are laminated vias that are not around the same center. The advantages of stacked vias include not only saving space and increasing density, but greater flexibility concerning the inner connections, better routing capacity and less parasitic capacitance. The downside of stacked vias is that they come with a higher cost than standard through-hole vias or blind/buried vias.

A microvia is merely a very small via. As you can imagine, microvias are very desirable to PCB designers — the smaller the diameter, the more routing space you have on the board and the lower the parasitic capacitance, which is essential for high-speed circuits. However, very small vias also require more drilling time and more off-center via moves. PCBCart defines microvias as vias with diameters of less than 0.1mm.

PCBCart has years of experience manufacturing PCB using blind and buried vias. No matter what it takes, we can make exactly the blind or buried via PCB you need for you. The following table shows design parameters on blind vias and buried vias manufactured by PCBCart:

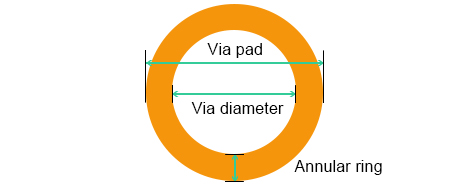

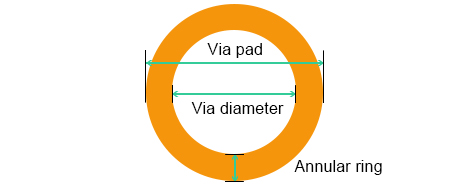

• Via Type Via Diameter

|

Via Type

|

Via Diameter

(max.)

|

Via Diameter

(min.)

|

Via Pad

|

Annular Ring

|

Aspect Ratio

|

|

Blind via (mechanical)

|

0.4mm

|

150μm

|

450μm

|

127μm

|

1:1

|

|

Blind via (laser)

|

0.1mm

|

100μm

|

254μm

|

150μm

|

1:1

|

|

Buried via (mechanical)

|

0.4mm

|

100μm

|

300μm

|

150μm

|

1:10

|

|

Buried via (laser)

|

0.4mm

|

100μm

|

225μm

|

150μm

|

1:12

|

Get in touch with us today to learn more about the various types of vias and how we use them to optimize the value of your PCB. Click the button below for a free quote.

Quote for PCBs with Blind/Buried vias

Helpful Resources

• Pre-order File Checklist

• PCB Design Tips to Better Take Advantage of PCBCart's Capabilities And Save Cost

• Step-by-step Instruction On Getting Bare Board PCB Price Within Seconds

• How to Design Blind/Buried Vias in High-Speed Digital Circuits

• 3 Important Elements You Don't Know about Buried and Blind Via in HDI Flex-rigid PCBs

• Failure Analysis on Blind Via for Empty Cave in PCB Filling Copper Plating