AOI, short for Automated Optical Inspection / Automatic Optical Inspection, is well responsible for quality control in terms of both Printed Circuit Board (PCB) fabrication and PCB Assembly (PCBA).

PCB successfully added to your shopping cart

As the Chinese New Year holiday is approaching, please note that our office will be closed from February 14th to 23rd (10 days). During this period, responses to inquiries may be delayed, but you can still submit quotes and orders online as usual.

English

English

English

English

English

English

Español

Español

Deutsch

Deutsch

Français

Français

Italiano

Italiano

日本語

日本語

ภาษาไทย

ภาษาไทย

Malay

Malay

AOI, short for Automated Optical Inspection / Automatic Optical Inspection, is well responsible for quality control in terms of both Printed Circuit Board (PCB) fabrication and PCB Assembly (PCBA).

It's almost impossible for current electronic devices to work without a circuit board. A PCB plays a critical role in electrical connection between components such as integrated circuits (ICs) that are assembled on bare boards applied in different electronic devices ranging from relatively simple equipment such as electronic watches, calculators, handheld computers, electronic communication equipment to advanced electronic devices like military, medical or aerospace products.

Due to the rapid progress of modern technologies and people's continuous higher demands for electronic devices, modern circuits have to be much more complicated than what they were just a few years ago. Furthermore, the introduction of Surface Mount Technology (SMT) leads circuit boards to develop towards miniaturization and high density. Nowadays, even an ordinary printed circuit board contains lots of solder joints and layers. Moreover, component size keeps gradually shrinking so that the massive application of 0402 and 0201 components leads to urgent necessity to ensure that correct components are applied with correct polarity and values.

When it comes to inspection methods for PCBs and PCBAs, manual inspection did make sense for a period of time. Nevertheless, it is hardly accepted for inspection of modern circuit boards since it fails to inspect their internal issues or defects.

Current market strongly calls for a reliable and fast inspection method, which is why AOI (Automated Optical Inspection) becomes so significantly important before products leave manufacturing house and function in customers' projects or devices. Moreover, AOI test enables a reduction of cost and to make issues exposed in the early phase.

Depending on visual methods, AOI test can be applied to detect a lot of surface defects including scratches, nodules, stains, opens, shorts, insufficient or excessive solder, incorrect components, missing components, incorrect polarity of components etc. As a matter of fact, these defects AOI is capable of going through belong to items of manual visual inspection that was mainly applied prior to the popularity of AOI inspection which is, however, capable of performing them quickly and accurately.

• Multiple inspection objects - AOI test works perfectly for both bare PCBs and PCBAs. For PCB inspection, defects are checked such as shorts, opens and insufficient solder. For PCBA inspection, issues are inspected including component soldering, polarity and values.

• Flexibility - Automated Optical Inspection can be arranged in any stage of manufacturing line in accordance customers' needs and cost tolerance capacity. In order to increase inspection efficiency and reduce corresponding cost, it's optimal to place it after reflow soldering because most defects result from nonconformance occurring during soldering process. The flexibility attribute of AOI test leads to reduction of cost since it is an in-process test and as soon as issues are discovered, manufacturing or assembly parameters can be instantly modified so that later products will be correctly produced. As a result, more products won't be rejected during functional test or final inspection.

• Low cost - Compared with Automated X-ray Inspection (AXI), post-reflow AOI is less expensive when it comes to solder joint defects inspection including bridges, broken joints, dry joints etc.

• Accuracy and Reliability

AOI test achieves its inspection process by scanning board surface. Depending on one or more high-definition cameras, this equipment can capture images of PCB surface with the help of numerous light sources including fluorescent lighting, LED lighting or infra-red or ultra-violet lighting. Then, comparison will be made between the captured image and board parameters that have been input into computer in advance so that differences, abnormalities or even errors can be clearly indicated by its built-in processing software. The whole process can be monitored at any second.

The analysis whether a board is perfect or features issues can be drawn by different algorithms applied by AOI. When it comes to simple applications inspection, pixel-counting algorithm is used containing the following methods.

• Template matching - Template-matching method, also called area-based method or correlation-like method, has been popular for a couple of decades. Based on pixel-by-pixel method, a small template is applied to a large inspection image through sliding template window. Then, normalized cross correlation (NCC) will be calculated between the template and inspection image. The larger the value of NCC is, the higher matching between them will be.

• Object recognition - Object recognition conforms to the same principle as view method in that difference is observed through comparison between an ideal image and the captured image of an object.

• Blob analysis - Blob analysis refers to a process during which the object is separated from the background first. Then with a pixel-based image applied, a blob is generated through grouping of object pixels to inspect issues of objects.

Owing to the progress of technologies and higher demand from market for efficiency and effectiveness, some new methods start to play a major role in PCB or PCBA inspection, among which vectoral imaging technology stands out.

As a pattern location search technology, vectoral imaging is based on geometric feature extraction instead of complete grey scale pixel values. Under such circumstances, the image analysis is not influenced by color changes or non-liner changes. Furthermore, vectoral imaging performs better in reduction of false failures due to the attribute of background elimination.

As a primary testing technique in PCB assembly, AOI applies to fast and accurate inspection of errors or defects occurring in PCB assembly process so that high quality of PCB assemblies can be ensured with no defects after their leaving assembly line. AOI can be applied both to bare PCBs and PCB assembly. In PCBCart, however, it is mainly applied to inspect SMT assembly line and for testing of bare circuit boards, bed of nail and flying probe are used instead.

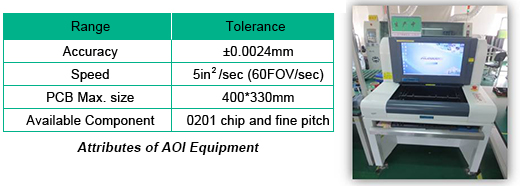

Professional Automated Optical Inspection machine of PCBCart is applied with its model ALD515.

PCBCart provides both online and offline AOI test to meet clients' different demands. Online AOI test features a higher degree of automation with no need of manual operation whereas offline AOI test features a lower degree of automation with the need of manual operation. Nevertheless, both of them share the same inspection principles, inspection objects and inspection methods. Click the button below to get a free quote.

Request PCB Assembly Quote With AXI

For more information about AOI test, please send us a message here. We'll reply you quickly.

Helpful Resources

• Comparison of AOI, ICT and AXI and When to Use Them during PCB SMT Assembly

• Pre-order File Checklist For Precise PCB Assembly Quote and Production

• Step-by-step Instruction On Requesting Free PCB Assembly Quotation

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

[email protected] [email protected]

[email protected] [email protected]

Thanks for your support! We'll go over your feedback in detail to optimize our service. Once your suggestion is picked up as the most valuable, we'll instantly contact you in email with a $100 coupon contained.