When people are being asked for their long-standing demands for electronic products, they will reply the following key words without hemming or hawing: smaller, lighter, faster and more multi-functional. In order to lead modern electronic products to be compatible with those demands, advanced printed circuit board assembly technologies have been widely introduced and applied, among which PoP (Package on Package) technology has won millions of proponents.

Introduction of Package on Package

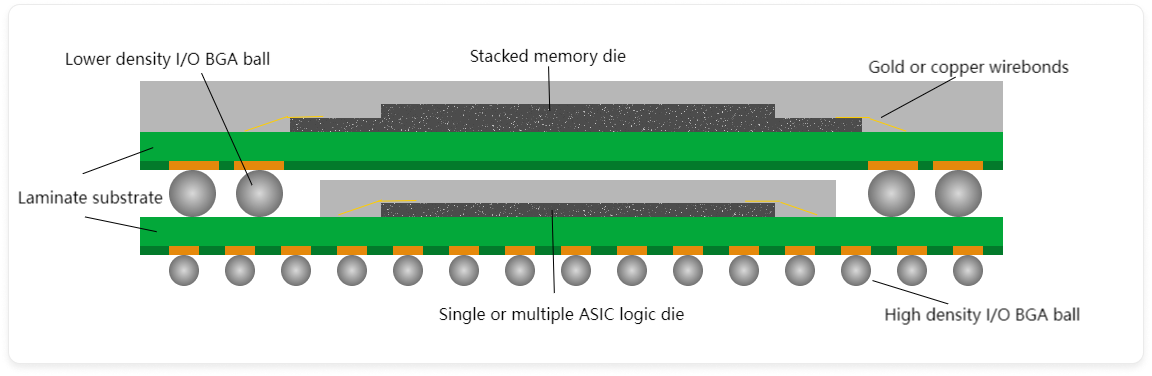

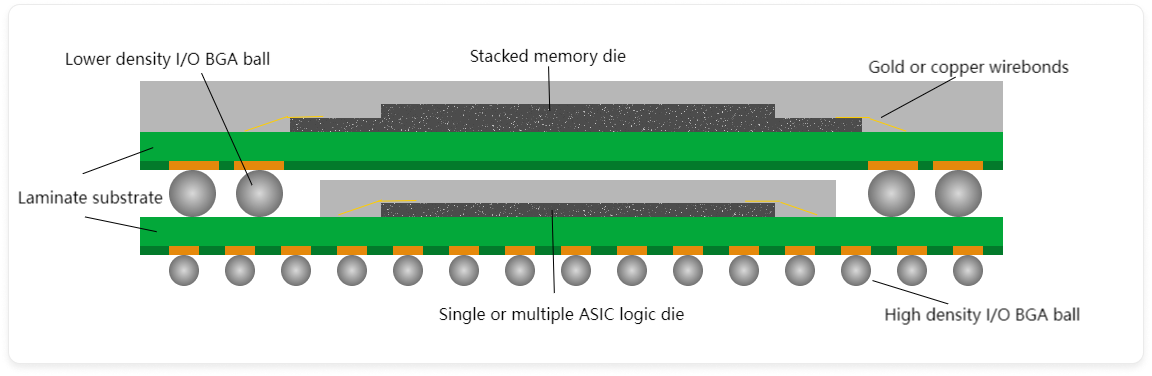

Briefly speaking, Package on Package is actually a process of stacking components or ICs (Integrated Circuits) together on a motherboard. As an advancing packaging method, PoP allows multiple ICs to be integrated into a single package containing logic devices and memory devices in top package and bottom package, leading to increased memory density and performance and reduced mounted area. PoP can be classified into two structures: standard structure and TMV structure. The standard structure contains logic devices in bottom package while memory devices or stacked memories in top package. As an upgraded version of a PoP standard structure, TMV (Through Mold Via) structure implements its internal connection between logic devices and memory devices through mold via in bottom package.

When it comes to its surface mount assembly process, package on package involves two key technologies: pre-stacked PoP and on-board stacking PoP. The key difference between them lies in times of reflow soldering: the former through two-time reflowing while the latter one-time.

Advantages of Package on Package

PoP technology is being widely applied by OEMs owing to its impressively advantages:

• Flexibility - Stacking structure of PoP provides OEMs such multiple selections of stacking that they are able to modify functions of their products at ease. For example, they are allowed to modify low-memory chip into high-memory chip to cater to newly-coming demands without need to change circuit board design of motherboard.

• Overall size reduction

• Shrinking overall cost

• Reducing motherboard complexity

• Improving logistics management

• Enhancing technology reuse level

Application Fields of Package on Package

Attributes of PoP work perfectly on portable electronic products including phones, digital cameras, portable media players, portable digital assistants and other devices concerning gaming and music.

Up to now, PCBCart has made smooth efforts and achievement on surface mount assembly, serving for various fields. Thanks to advanced technologies, rigorous manufacturing standards, up-to-date equipment and professional engineering staff, we are beefing up products up to custom designed products.

For more information about PoP and other PCB assembly capabilities, please send us a message here, we will get back to you with full details.

Reach PCBCart For FREE PCB PoP Assembly Quote