PCB panelization is one of the most essential modern tools we have when it comes to PCB manufacturing efficiency. PCB panelization can not only improve the production efficiency of PCs and reduce delivery time, but also solve many logistics problems by using PCB panels correctly, including how to manufacture smaller printed circuit boards or boards with unusual shapes. When it comes to PCB assembly, panelization allows manufacturers to reduce labor costs and more easily control the quality of the product.

PCBCart Expertise in PCB Panelization

In the area of PCB panel fabrication and panel assembly, you can be confident when you choose PCBCart. With more than two decades of experience, we've seen it all and have the knowledge and skills to meet all your PCB panelization needs.

There are four types of PCB panelization:

• Order Panelization: Order panelization is the most popular type of panelization because you can use it in all circumstances, which means you can apply it to the most manufacturing situations. Order panelization also creates few operating difficulties and does not affect printing quality.

• Rotation Panelization: There are some situations where standard order panelization will waste more space than necessary. We can avoid this by rotating the board either 90 or 180 degrees. This type of panelization is known as rotation panelization, for obvious reasons.

• Double-Side Panelization: Another space-saving panelization innovation is double-side panelization, where we panelize both sides of the PCB on one side as a panel. Double-side panelization is suitable for mass manufacturing — it saves specimen curve material and increases SMT overall efficiency while lowering manufacturing costs.

• Combination Panelization: Also known as characteristic panelization, this is a form of panelization involving combining different types of printed circuit board. Learn more about the different kinds of panelization, their benefits and drawbacks and the best situations in which to apply them here.

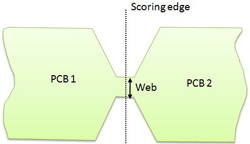

What is V Scoring?

V Scoring is the creation of the V-shaped breaking lines that connect printed circuit boards so you can separate them easily, a process that further increases efficiency. When it comes to V scoring, it's important to cut to an equal depth, one-third on top and one-third on the bottom, leaving the middle part - "the web" - connected. Not all boards are necessarily suitable for V scoring. PCBCart requires panels to be at least 0.6mm thick for V scoring.

Enjoy PCB Panelization Service for Free With PCBCart

If you're ready to enjoy all the benefits of PCB panelization, PCBCart can help you get started with entirely free panel file generation. Benefit from our 20 years of manufacturing experience and highly-qualified engineering team with this additional service.

To learn more about PCB panels, V scoring, PCB panelization methods, your panelization requirements or anything else about our PCB services, please get in touch with us today. If you're interested in circuit board panel, contact us now. We'll be back to you with an estimate as soon as possible.

Helpful Resources

• The Surprising Secret to Designing Combination Method of PCB Panels

• Design PCBs to Better Take Advantage of PCBCart's Manufacturing Capabilities and Save Cost

• Guide on Getting PCBs Prices in Panel Type