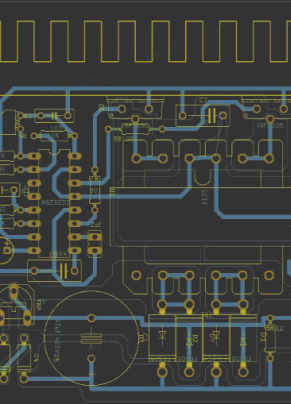

PCB Layout Design

As a company that has served the global electronics industry for more than 20 years, PCBCart provides a one-stop electronic manufacturing service that starts with the PCB layout.

Start Your Layout Quote

As the Chinese New Year holiday is approaching, please note that our office will be closed from February 14th to 23rd (10 days). During this period, responses to inquiries may be delayed, but you can still submit quotes and orders online as usual.

English

English

English

English

English

English

Español

Español

Deutsch

Deutsch

Français

Français

Italiano

Italiano

日本語

日本語

ภาษาไทย

ภาษาไทย

Malay

Malay

PCB Layout Design

As a company that has served the global electronics industry for more than 20 years, PCBCart provides a one-stop electronic manufacturing service that starts with the PCB layout.

Start Your Layout Quote

PCB Layout Capabilities

| Maximum number of layers |

64 |

| Maximum number of pins |

150,000+ |

| Maximum number of connections |

120+ |

| Minimum line width |

3mil |

| Minimum line spacing |

3mil |

| Minimum via hole |

6mil (4mil for micro via do with laser) |

| Maximum number of BGAs |

120+ |

| Minimum BGA pitch |

0.3mm |

| Maximum number of BGA pins |

18865 |

| Maximum Speed Signal |

224G-PAM4 |

Chip and Module Solutions for Advanced PCB Layout

From Data Centers to Automotive Systems: Master Multi-Industry Processor, FPGA, Power, and Memory Design Strategies.

Data Center/Server Processors

Networking/Communication Processors

Industrial Control Processors

Mobile/Embedded Processors

Automotive Processors

High-Performance Computing FPGAs

Military/Industrial-Grade FPGAs

Low-Power Embedded FPGAs

Multi-Channel Power Management ICs (PMICs)

Automotive-Grade Power Chips

High-Density DC-DC Converters

High-Speed Network Interfaces

High-Speed Serial Interfaces

Data Converters (ADC/DAC)

High-Performance DRAM

Industrial-Grade Storage

Low-Power Memory

Autonomous Driving Domain Controllers

Vehicle Body Control & Safety

Smart Cockpit Domain Controllers

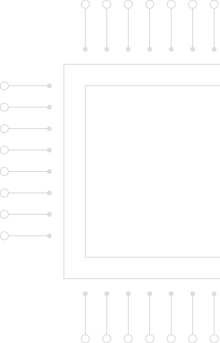

PCB Layout Design Process

Layout Work Flow at PCBCart

PCB Layout Design Cycle

| PCB board PIN number | Lead Time (working days) |

|---|---|

| 1-1000 PIN | 3-5 days |

| 2000-3000 PIN | 3-8 days |

| 4000-5000 PIN | 8-12 days |

| 6000-7000 PIN | 12-15 days |

| 8000-9000 PIN | 15-18 days |

| 10000-12000 PIN | 18-20 days |

| 13000-15000 PIH | 20-23 days |

| 16000-19000 PIN | 23-30 days |

Note: The design cycle of the above PCB board PIN number is the regular delivery period. The accurate design cycle is based on the time when the customer provides complete information and the difficulty of the PCB board for comprehensive evaluation.

Advantages of PCB Layout Service at PCBCart

Prolific + Professional Engineers

Significant Seniority: More than 20 years of Industry Experience. Efficient Design: Ordinary PCB layouts can be completed in minutes.

Excellence in Quality

Self-inspection: Detailed checks on design aspects using a checklist. Expert Review: Senior experts assess design, manufacturability, testability, EMC, and thermal factors.

Quick-Turn Assembly Services

Parallel Design: Reduces delivery time by 30-50%. In-House Production: Enables immediate manufacturing.

Expert & Secure Layout Solutions

Software Compatibility: Proficient in Altium, PADs, OrCAD, EAGLE, and KiCAD. NDA Protection: Mandatory NDAs to safeguard customer innovations.

One Board Success

Right the First Time: Streamlining PCB development, reducing R&D iterations. Rapid Market Entry: Seizing the First-Mover Advantage.

Cost Optimization

Manufacturing Compatibility: Increased supplier flexibility, and reduced supply chain risk. Optimized for Scale: Design considerations for R&D and manufacturing.Quality Assurance

We ensure excellence through self-checks, mutual inspections, expert reviews, and stringent standards.

Expert Guidance

Comprehensive 'Design Guidelines' and 'Design Specifications' offer additional technical recommendations beyond layout.

Self-Inspection

Comprehensive checks across all design facets (layout, wiring, thermal, etc.) using detailed checklists and strict quality systems.

Mutual Inspection

Standardized peer reviews and thorough Design for Manufacturability (DFM) analysis.

Expert Review

Final review by senior engineers, encompassing design principles, DFM, Design for Testability (DFT), Signal Integrity (SI), Power Integrity (PI), and Electromagnetic Compatibility (EMC).Industry Involved

Telecommunications

Switches, routers, 4G/5G equipment, network transmission, optical networks.

Medical Technology

Ultrasound, MRI, CT, IVD, temperature measurement, blood analysis, digital X-ray.

Computing

Servers, laptops, storage, tablets, cloud computing.

Industrial Automation

AI, machine vision, smart manufacturing, smart grids, clean energy, machinery, and fire safety.

Semiconductor

Integrated circuits, consumer electronics, communication systems, photovoltaics, power conversion.

Rail Transportation

Transit vehicles, electromechanical systems, autonomous operations, and dispatch systems.

Consumer Electronics

Smartphones, cameras, wearables, VR, IoT devices.

Electric Vehicles

Powertrain, chassis, autonomous driving, intelligent systems, and electronic systems.

Need Help with a PCB Layout?

Streamline your go-to-market with our expert PCB layout services. Contact us to discuss your project needs with our engineering support. Your success is our specialty.

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

[email protected] [email protected]

[email protected] [email protected]

Thanks for your support! We'll go over your feedback in detail to optimize our service. Once your suggestion is picked up as the most valuable, we'll instantly contact you in email with a $100 coupon contained.