PCBCart desires to be your reliable one-stop PCB services provider. We understand superior quality PCBs, short turnaround time, excellent customer services and economical prices contribute to fulfilling your requirements and bringing you back, among which PCB quality lies on the top of your requirement list. Therefore, we follow the most rigorous quality standards throughout circuit boards prototyping, manufacturing and assembly. Currently, we're fully ISO9001:2008, IATF16949, UL and RoHS certificated. You can rely on us for custom PCB production and assembly.

What is ISO 9001:2008 and ISO 9001:2015?

ISO 9001 is a family of international quality management standards and guidelines aiming to promote global companies and organizations' capabilities to meet and exceed the needs and expectations of customers by efficiently and effectively improving the quality of their products and services. Aspects ISO 9001 quality management system is involved with cover from context of the organization, leadership, planning, operation, support, performance evaluation to improvement.

ISO 9001:2015 is the latest version of this standard, replacing ISO 9001:2008, with updated requirements to better support organizations in improving quality management and meeting customer expectations.

Under the specific requirements of ISO 9001:2015, PCBCart has been striving for consistently providing products exceeding and enhancing customer satisfaction rate with requirements implemented in the process of PCB fabrication and assembly and for efficiently improving the quality of products and services.

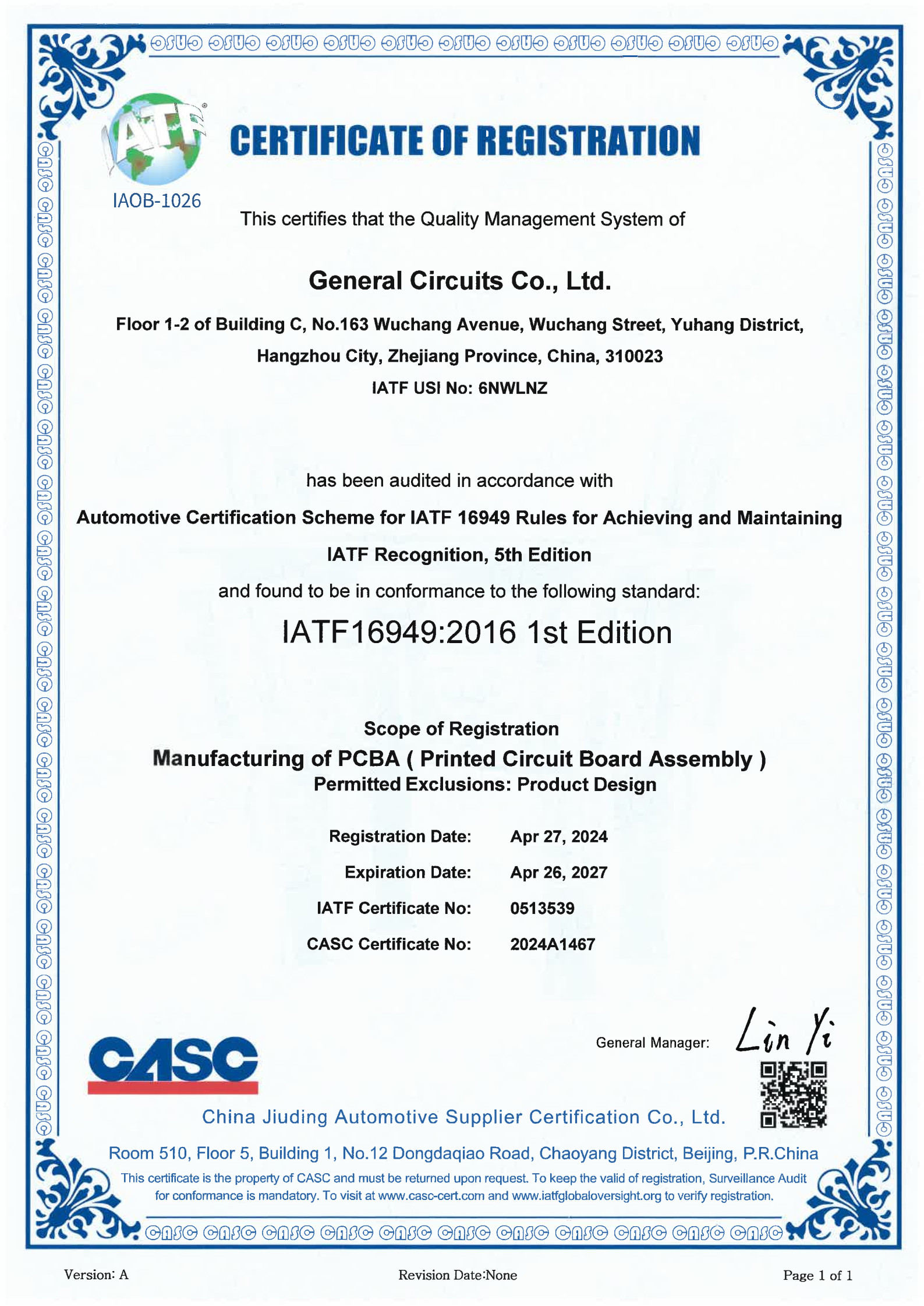

What is IATF16949?

IATF, a short form of International Automotive Task Force, is a specialized agency established by world’s leading automotive manufacturers and associations in 1996. Combining the regulations and standards of ISO9001:2000, IATF16949:2000 came out and the latest version is IATF16949:2016.

IATF16949 is actually a set of quality management standard that requires electronics manufacturers to guarantee automotive products’ quality and security and to improve the performance and reliability of automotive products.

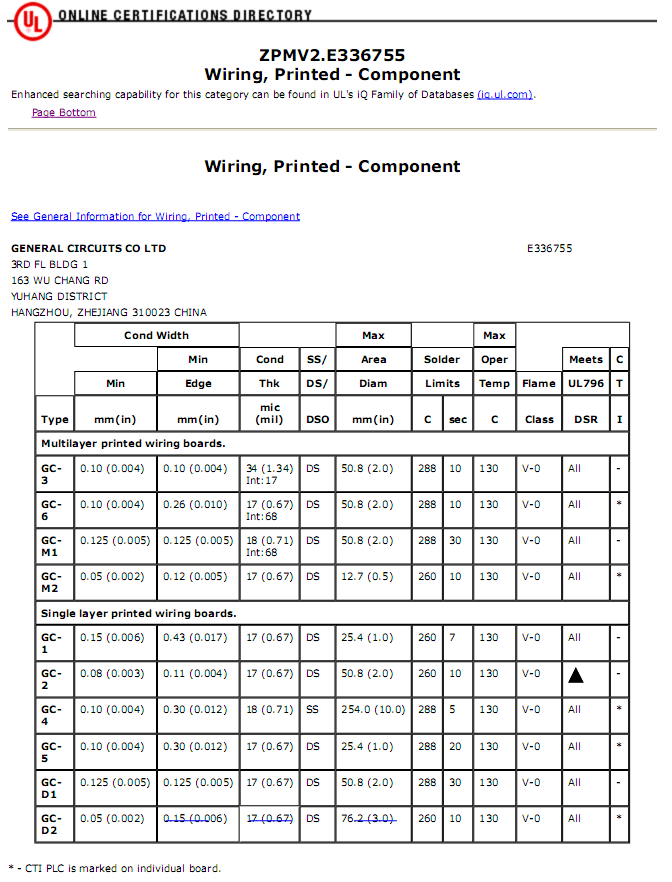

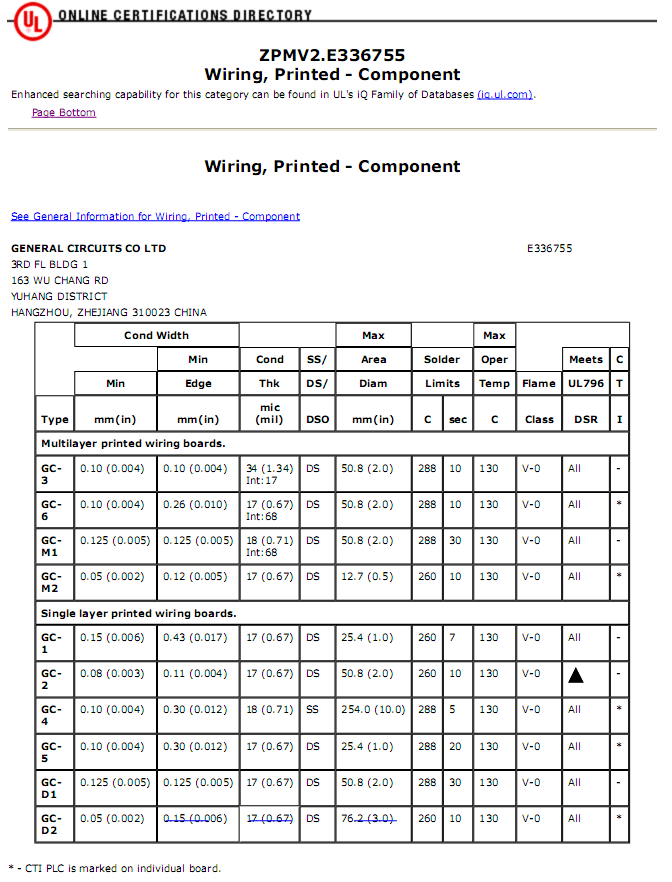

What is UL?

Applicable for circuit boards and power supplies, UL listing service requires manufacturers to rigorously test their products by conforming to correct procedures in order to minimize product hassels. Aspects UL classification service cover range from specific risks only, performance under specified conditions, regulatory codes, other standards to such other conditions UL considers desirable, allowing customers to be aware of different standards of products.

With UL certificated, PCBCart has been promoting testing capabilities and up to now, we're capable of carrying out first article inspection, AOI (Automated Optical Inspection), X-ray inspection, etc. in order to provide high-quality products and services for customers.

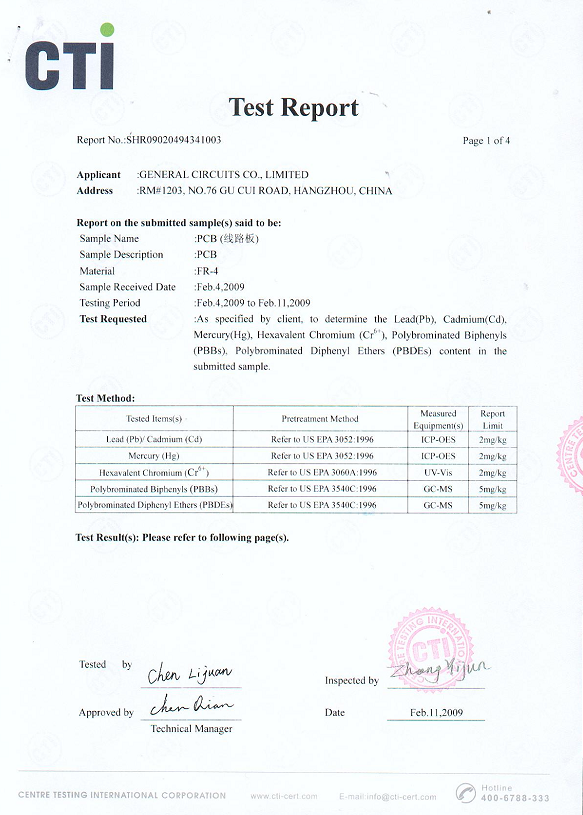

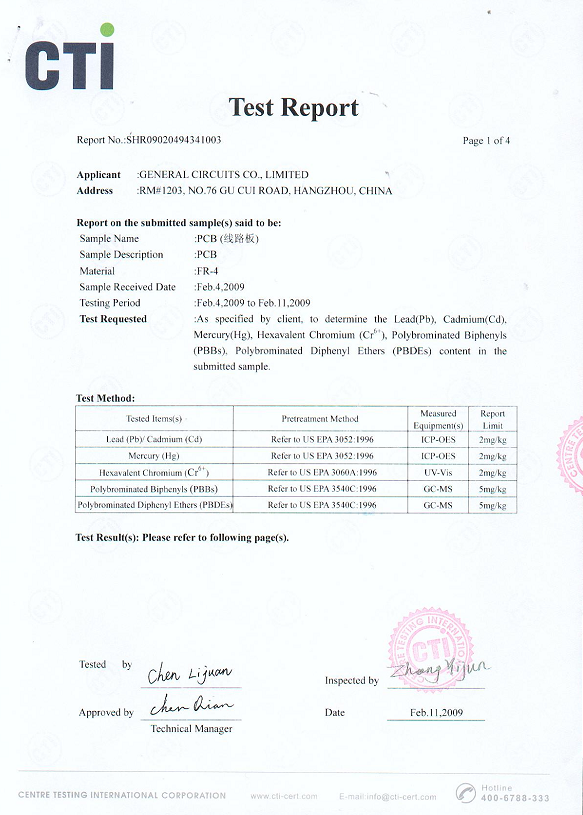

What is RoHS?

RoHS, short for Restrictions of Hazardous Substances, refers to a series of restrictive laws of application of 6 hazardous substances in the manufacturing of electronic and electrical equipment, including Lead (Pb), Mercury (Hg), Cadmium (Cd), Hexavalent Chromium (Cr VI), Polybrominated Biphenyls (PBB) and Polybrominated Diphenyl Ethers (PBDE). Starting from manufacturers in EU since 2003, RoHS guidelines have now been widely accepted almost all over the world, covering the whole electronics industry and partial electrical products. According to RoHS regulations, maximum concentration is specified for each type of restricted substances and practical concentration should never be higher than that.

PCBCart is able to provide custom PCBs and assembly with surface finishes compatible with the requirements of RoHS such as lead-free HASL, ImAg, ENIG, etc. Furthermore, we also provide RoHS compatible laminate material that can withstand high temperature in PCB assembly process, catering to higher environment-friendly requirements of customers.

PCBCart Manufactures PCBs Professionally But at Lower Cost