Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of a printed circuit board (PCB). This technology utilizes small, intricate parts placed precisely on the PCB's surface, offering high mechanical strength and efficient space utilization. SMT is suitable for prototyping, mass production, and PCB repair, featuring the use of solder paste for secure component attachment. SMT assembly optimizes space by placing leads and components on the same side of the PCB, making it ideal for modern, compact electronic devices.

Key Benefits:

• High-speed circuit assembly

• Enhanced fabrication automation and density

• Cost-effective and quick production

• Maximum design flexibility

• Superior performance and accuracy

Advanced SMT Assembly Line:

• Reliable and high-quality PCB production

• Fast and flexible prototyping to production-ready components

• Expertise in Single and Double-sided SMT PCB assemblies

The SMT process can be divided into pre-process and in-process. Before it starts, various PCB documents, such as circuit board data (Gerber), bill of materials (BOM), and auxiliary data, etc. need to be prepared, which are the basis of SMT technology processing. After the preparation work is fully completed, it will be carried out.

We provide one-stop solutions including PCB fabrication, components procurement and PCB Assembly services. Owing to stringent manufacturing rules and regulations, increasing technological knowledge and enthusiasm to strive for the latest technologies, we have accumulated numerous capabilities to deal with different SMT package type such as BGA, PBGA, Flip chip, CSP and WLCSP.

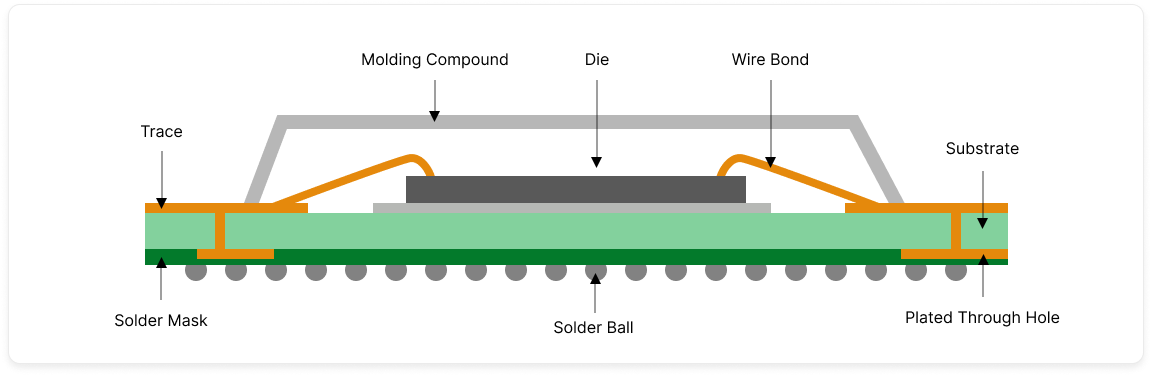

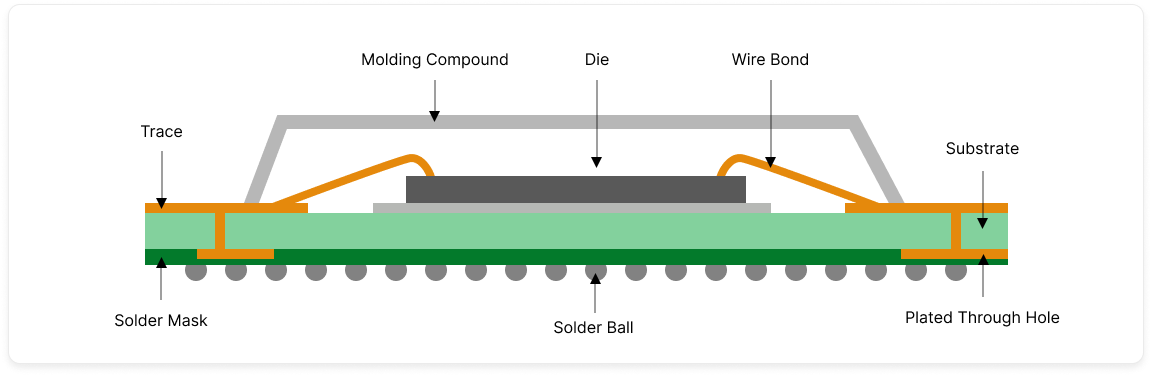

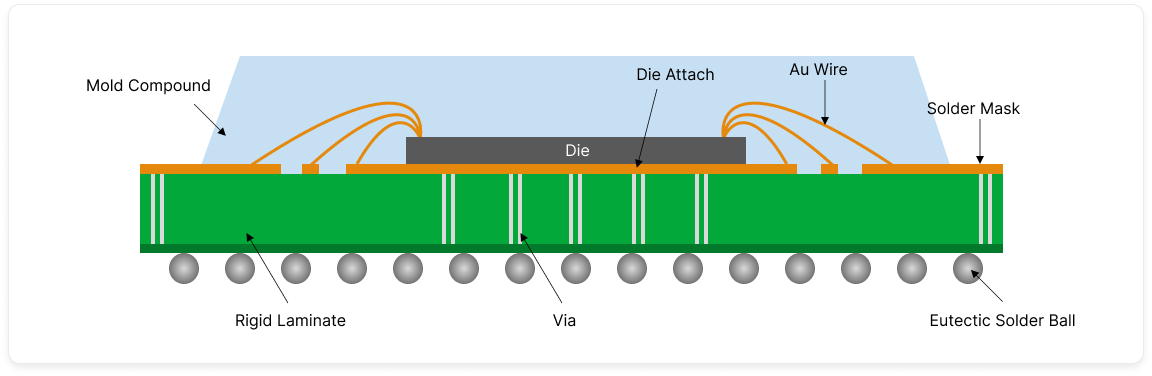

BGA

BGA, short for ball grid array, is a form of SMT package that is increasingly used in integrated circuits. BGA is beneficial to the improvement of solder joint reliability.

BGA exhibits the following advantages:

• Efficient application of PCB space - BGA package places connections beneath SMD (Surface Mount Device) package instead of around it so that space can be largely saved.

• Improvement in terms of thermal and electrical performance - Since BGA package helps to reduce inductance of power and ground planes and impedance controlled signal lines, heat can be moved away from pad, beneficial to heat dissipation.

• Increase of manufacturing yields - Owing to progress of solder reliability, BGA can maintain relatively large space between connections and high-quality soldering.

• Package thickness reduction - We specialize in handling fine pitch components assembly and up to now we can deal with BGAs whose minimum pitch can be as small as 0.35mm.

When you place a full turn-key PCB assembly order concerning BGA package, our engineers will, first of all, check your PCB files and BGA datasheet to summarize a thermal profile in which elements have to be taken into consideration such as BGA size, ball material etc. Prior to this step, we will check your PCB design for BGA and provide a Free DFM check to be aware of elements essential to PCB assembly including substrate material, surface finish, soldermask clearance, etc.

Due to attributes of BGA package, Automated Optical Inspection (AOI) fails to meet the inspection needs. We undertake BGA inspection by Automated X-ray Inspection (AXI) equipment capable of inspecting soldering defects at the early stage prior to volume manufacturing.

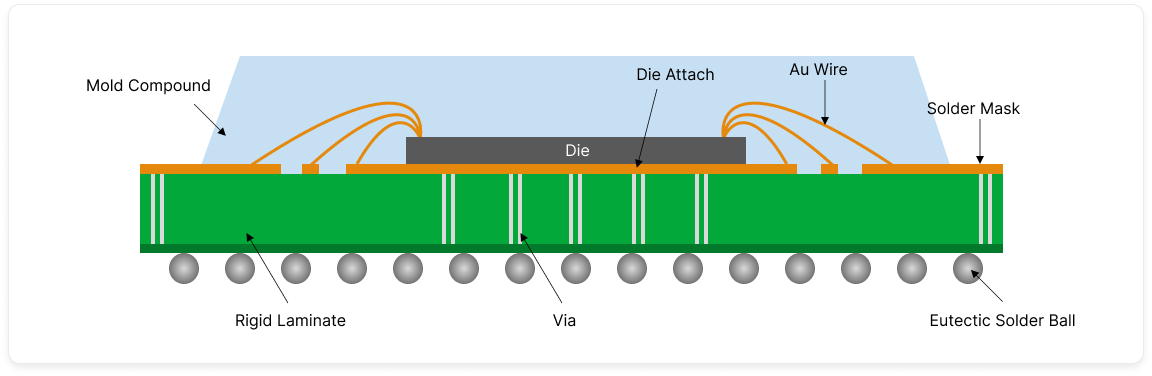

PBGA

PBGA (Plastic Ball Grid Array), is a popular packaging form for medium-high level I/O devices. Depending on laminate substrate contains extra copper layers inside, it is good to heat dissipation and can cater to larger body sizes & number of balls to meet a wider range of needs. Its advantages include:

• Requiring low inductance

• Making surface mount easier

• Relatively low cost

• Maintaining relatively high reliability

• Reducing coplanar issues

• Obtaining relatively high-level thermal and electrical performance

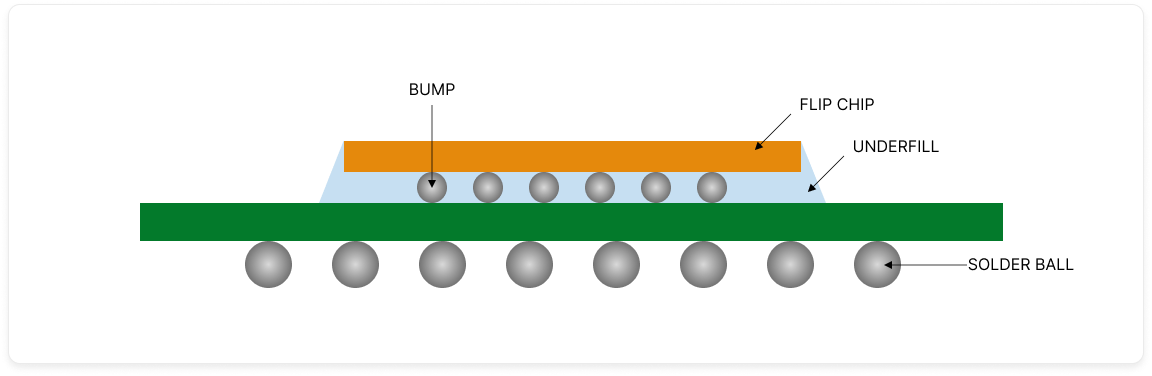

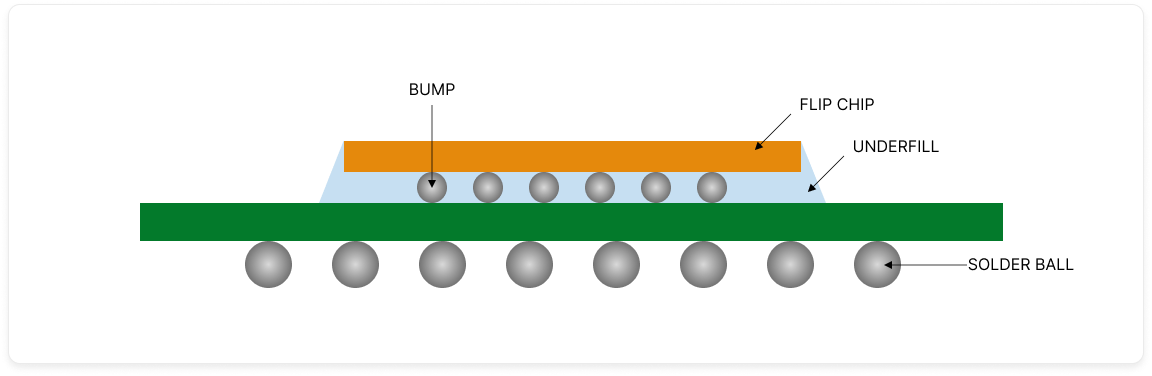

Flip chip

As a method of electrical connection, flip chip connects die and package substrate by directly facing down IC in order to make it attached to substrate, circuit board or carrier. Merits of flip chip include:

• Reducing signal inductance and power/ground inductanc

• Decreasing the number of package pins and size of die

• Increasing signal density

CSP and WLCSP

Up to now, CSP is the latest form of package, short for chip scale package. As the description its name indicates, CSP refers to a package whose size is similar to that of a chip with defects concerning bare chips eliminated. CSP provides a packaging solution that is denser and easier, cheaper and faster. And the following features of CSP helps lead to increasing of assembly yields and lower manufacturing cost.

CSP is so popular and efficient in this industry that up to now there are over 50 types of CSPs in its family and the number is still growing every day. A lot of attributes and features of CSP are contributive to its wide popularity in this field:

• Reduction of package size - It can obtain a packaging efficiency higher than 83%, largely increasing density of products.

• Self alignment - It can be self aligned during PCB assembly reflow so that it makes SMT easier.

• Lack of bent leads - Without participation of bent leads, coplanar issues can be greatly reduced.

WLCSP, short for wafer level chip scale package, is a real type of CSP since its finished package exhibits a chip-scale size. WLCSP refers to IC packaging technology at the wafer level. A device with WLCSP is actually a die on which an array of bumps or solder balls is arranged at an I/O pitch, meeting the requirements of traditional circuit board assembly processes. Its advantages primarily include:

• Inductance from die to PCB is the smallest;

• Package size is greatly reduced with density degree improved;

• Thermal conduction performance is tremendously enhanced.

Up to now, we are capable of dealing with WLCSP whose both minimum Within-Die pitch and Across-Die pitch can reach 0.35mm.

0201 and 01005

As electronic market and products advance, growing trend of miniaturization of cell phones, laptops etc. is constantly driving for components with smaller sizes. 0201 and 01005 are extremely popular in electronic market due to the following advantages:

• Tiny size making them quite welcome in space-constrained end products;

• Excellent performance in functionality enhancement of electronic products;

• Compatible with high density needs of modern electronic products;

• Very high-speed applications.

To achieve assembly capabilities of 01005, we've succeeded in dealing with aspects concerning its assembly process including PCB design, components, solder paste, pick and placement, reflow, stencil and inspection. Our experience helps us summarize that in terms of post-reflow issues, compared with components with other types of packages, components packaged with 01005 perform better in issue elimination such as bridging, tombstone, edge-standing, upside-down, missing part etc.

Reach PCBCart For FREE PCB Assembly Quotation