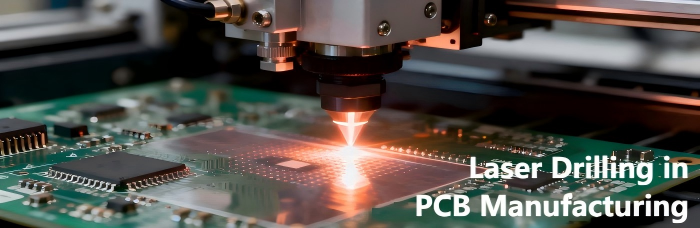

The electronics industry is fast-growing, while the demand for precision and miniaturization in printed circuit board manufacturing continually increases. Printed circuit boards are at the very foundation of electronic devices and ensure functionality and performance. In order to meet such a requirement, PCBCart relies on advanced laser drilling technology that is making a real difference to PCB manufacturing. This article will outline the applications and advantages of laser drilling, considered critical in modern electronic production.

The Rise of Laser Fine Drilling

In the era of an increasingly intelligent global manufacturing landscape, there is an increasing need to process with higher precision. Under this background, laser fine processing represents an important technology, where laser fine drilling takes on a particularly important value. The technique is now in wide use in the PCB industry, with a maximum accuracy of up to 2μm that has no parallel. Such precision is indispensable for producing small, micro, and invisible holes, fulfilling the specific needs of modern electronic applications.

Why Laser Drilling is Essential for PCBs

Accurate hole drilling forms the basis for making reliable interconnections through the multilayer structure of a PCB. Laser drilling has become the preferred method because of its very high accuracy and efficiency, unlike mechanical drilling. Mechanical drilling involves physical contact that creates vibrations and can possibly cause damage to the PCB; laser drilling is non-contact, and it precludes these risks and hence provides reliability and integrity for the board.

Key Benefits of Laser Drilling

Non-Contact and Vibration-Free Processing

One of the main advantages of laser drilling is that it is a non-contact process, thus eliminating the possibility of damage caused by stress and vibration associated with mechanical techniques. Consequently, this will ensure the structural strength and functionality of the PCB.

Unparalleled Accuracy

Laser drilling is done with beams that possess high coherence, directionality, brightness, and monochromaticity. Focused energy input with minimal heat-affected zones promotes less material deformation, hence high accuracy in the processing. This makes laser drilling superior for applications that demand high precision.

Capability for High Aspect Ratios

This technology is essential in the fabrication of vias with high aspect ratios, which are necessary for high-density interconnect boards that enable the miniaturization trends driving consumer electronics.

Material Versatility

This can be done on a wide range of substrate materials, including conventional FR-4 laminates to advanced polyimide substrates, which provide for consistent quality across various PCB applications regardless of material differences.

Laser Drilling Technologies

Most of the laser processing in the manufacture of PCBs today is done using two primary technologies:

CO2 Laser Processing: This technique is highly used for larger-sized microvias with diameters greater than 100 μm. CO2 lasers are quite productive; they efficiently penetrate most organic materials, hence suitable for high-throughput processes.

UV Laser Technology: UV lasers are best suited for drilling smaller microholes of less than 100 μm. "Cold ablation" is the process by which UV lasers achieve minimal heat-affected zones. This reduces thermal stress, especially in multi-layered PCBs made from composite materials.

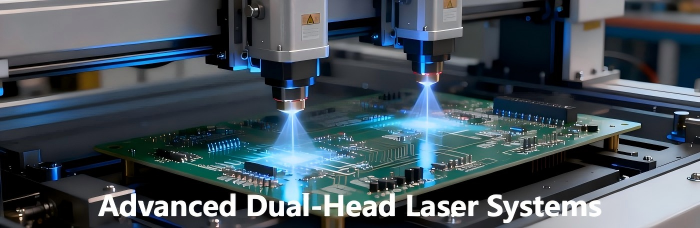

Advanced Dual-Head Laser Systems

Consequently, dual-head laser systems have been advanced to meet the expanding demand in producing micro-holes and ensuring increased efficiency:

Double-Head UV Drilling Systems: These are appropriate for the fabrication of very small holes, less than 80 μm, suitable for intricate integrated circuits that require precise detailing.

Double-Head CO2 Laser Systems: They employ high-frequency, Q-switched CO2 lasers that enable fast drilling, although the quality might differ depending on the intended application, such as blind hole drilling.

Combined Systems: Taking advantage of the strengths of both CO2 and UV, these lasers can offer a versatile solution that can handle diverse drilling requirements.

Impact on Quality of PCB

Improved Quality of Plating: Laser drilling produces holes with smooth, uniform walls, which are quite essential for achieving reliable copper plating and allowing good electrical connections between layers.

Efficient Debris Management: The process generates minimal debris, limiting the possibility of contamination and hence maintaining high standards of production.

Improved Desmear Processes: Consistent hole geometry minimizes smeared residue, allowing more effective desmearing processes with better connectivity and reliability.

Considerations for Optimal Laser Drilling

It is essential, when laser drilling is applied, to pay attention to the different absorption rates of the various materials involved. Homogeneity in PCB stack-up can be achieved at this stage; therefore, precise and uniform drilling can be ensured, which requires that parameters in drilling should be cautiously tuned to match the requirements of the project or materials involved.

Applications in High-Quality PCB Production

The precision and versatility of laser drilling make it indispensable in a wide range of high-demand applications, including:

Consumer electronics: Smartphones, tablets, and wearables are among the devices having compact and efficient designs due to HDI boards with microvias produced via laser drilling.

Automotive Systems: As modern vehicles increasingly incorporate ADAS, precision vias are crucial for the reliability of safety-critical systems.

Medical Devices: The assurance of faultless electrical interconnections, which is crucial in life-sustaining and diagnostic equipment in medical technology, can be achieved with precision by laser drilling.

Telecommunications: For 5G infrastructure, high-frequency boards require unparalleled signal integrity. Precise and reliable laser drilling will enable this.

Rapid progress in the electronics industry encourages more and more precise and miniaturized fabrication of printed circuit boards. Laser drilling technology has been the forerunner in this development due to its high level of precision and efficiency necessary in today's electronics. PCBCart uses laser fine drilling to achieve superior accuracy, structural integrity, and material versatility through a wide range of applications. Non-contact processing, high aspect ratio vias, and effective management of debris further characterize laser drilling as an indispensable method in making quality PCBs. Such a competitive edge allows the company to serve a wide array of growing industries, ranging from consumer electronics to automotive, medical treatment, and telecommunications.

At PCBCart, we are committed to utilizing the latest developments in laser drilling to offer you superior PCB solutions. Our use of sophisticated CO2 and UV laser technologies, with advanced dual-head systems, ensures precision and efficiency on all projects. Through this commitment to innovation, we have the ability to provide high performance at the precise demands of those industries that depend on it. Whether you need the power of miniaturization for consumer devices or require fine detail for high-frequency communication boards, the comprehensive suite of services offered by PCBCart can be staged to align with your specific needs. Please contact us today to get a quote for your project and experience unparalleled quality, along with a customer-centric approach that will propel your projects to new heights within the tech landscape.