The selection of solder paste plays a key role in the fast-changing industry of surface mount technology and printed circuit board assembly. Solder paste-a mixture of minute-sized metal alloy particles in flux-forms an important role in developing electrical and mechanical connections between components and PCBs. We at PCBCart believe that the right selection of solder paste types-Types 3, 4, or 5-can greatly affect both the quality and efficiency of your production process.This detailed guide takes you through these types as classified by the IPC standard J-STD-005 and offers insight to help in making an informed choice.

Understanding Solder Paste and Its Importance

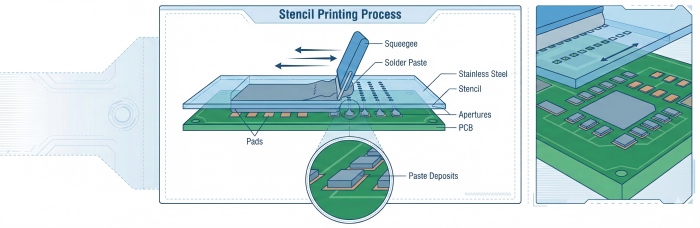

Solder paste is a mix of micron-sized metal alloy particles suspended in a flux medium. It consists of common tin, silver, and copper for lead-free applications and is generally stenciled onto PCBs, yielding high accuracy deposits on component pads.The resulting paste melts in the reflow oven to create a solid, reliable interconnection.

Solder paste selection is vital because of its effect on how well the paste prints through a stencil, adheres to the PCB, and performs at reflow. It is especially important on fine pitch components where precision becomes critical, enabling the process to avoid a variety of defects.The IPC classification of solder paste by particle size includes Types 3, 4, and 5, and all three are still commonly utilized in today's modern SMT applications.

Solder Paste Type Classifications

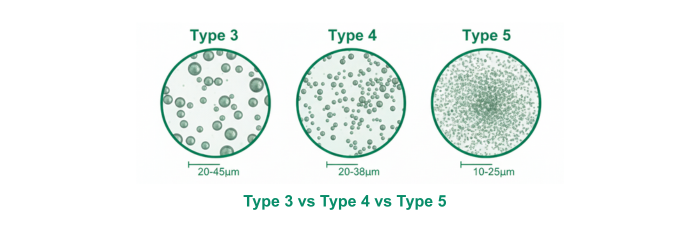

The IPC standard J-STD-005 classifies solder paste according to the particle size of solder powder as follows:

Solder Paste Type 3: The Industry Standard

Particle Size: 20-45 micrometers (μm)

Applications: Type 3 solder paste is versatile and can be widely used for standard SMT applications with components having pitches of 0.65 mm or larger.It offers a balance of cost and performance, making it ideal for many assembly projects. Type 3 has bigger particles, which reduce the possibility of stencil clogging but are not good for ultra-fine pitch components below 0.5 mm.

Solder Paste Type 4: Precision Applications

Particle Size: 20-38 micrometers (μm)

Applications: With finer particles, Type 4 solder paste is best suited for applications that need higher accuracy, like smartphones and tablets, or even for any dense PCB layout. It is perfect for printing through smaller stencil apertures (0.5 mm or smaller), improving print definition while reducing the possibility of bridging in fine pitch assemblies.

Solder Paste Type 5: For Advanced Miniaturization

Particle Size: 10-25 micrometers (μm)

Applications: Type 5 solder paste is designed for the most challenging applications requiring ultra-fine pitch components below 0.4 mm, such as chip-scale packages and micro BGAs. While offering unmatched precision, Type 5 requires advanced stencil technologies and is more sensitive to environmental conditions, often reserved for cutting-edge electronics where performance justifies the cost.

The Impact on Stencil Printing

Particle size is again very important in stencil printing, since the stencil's apertures should be equivalent to the solder paste particles in size for actual paste transfer and deposit accuracy.

Type 3 is intended for use in stencils with apertures of 0.65 mm or larger and is ideal for standard components, ensuring smooth paste release.

Type 4 provides better control with apertures of about 0.5 mm, which is critical for smaller pads and tight pitches.

Type 5 requires precision stencil design with apertures down to 0.3 mm or less, supporting ultra-dense layouts where space is at a premium.

An appropriately matched solder paste type and stencil design are key to minimizing defects such as insufficient solder volume or bridging.

Key Considerations for Solder Paste Selection

When choosing the right solder paste, consider several factors together with particle size:

Alloy Composition: It affects the melting temperature and joint strength. The typical SAC305 alloy contains 96.5% tin, 3% silver, and 0.5% copper.

Flux Type: The influences of post-assembly cleaning requirements include no-clean flux, which is in widespread use for minimizing cleanup, and water-soluble fluxes for high-reliability applications where thorough cleaning is required.

Viscosity and Thixotropy: Affect how the paste flows during printing and holds its shape after deposition.

Storage and Shelf Life: Finer particle pastes, Types 4 and 5, are more sensitive to oxidation, requiring careful storage in cool, controlled environments in order to maintain their performance.

Practical Tips for Handling and Application

Following are some best practices that will help maximize solder paste performance:

Stencil Thickness: Use a thickness that complements the type of paste.Thinner stencils are good for finer pastes such as Type 4 and 5.

Printing Speed: The speed has to be calibrated based on the paste type.Finer pastes usually require slower speeds to achieve proper release.

Environmental Controls: Controlled temperature and humidity 20-25°C, 40-60% relative humidity are recommended for optimum paste performance and shelf life.Deposit Inspection: Regularly inspect paste deposits to verify volume and alignment, catching any potential defects early in the process.

Proper Storage: Refrigerate paste when not in use and allow it to reach room temperature before opening to avoid condensation issues.

Overcoming Common Challenges

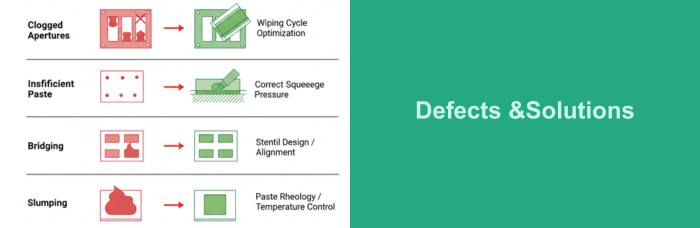

Challenges with solder paste, particularly the finer ones, can arise. Here are solutions:

Clogging of Apertures in Stencil: Application of proper stencil design and cleaning regularly.

Insufficient Paste Volume: Check stencil thickness and aperture size. Also, the temperature and viscosity of the paste should be proper.

Bridging Occurs in Fine Pitch Components: Optimize the stencil design using small apertures with suitable finer paste.

Paste Slumping: improve viscosity by appropriate storage conditions, and/or consider a better paste in terms of thixotropic properties.

A full understanding of the differences within solder paste Types 3, 4, and 5 is very crucial in attaining quality in PCB assembly. The choice of an appropriate solder paste type, if matched with the specific requirements of your project, will ensure that you achieve reliable solder joints with minimal defects. Whether consumer electronics or advanced medical devices are assembled, mastering solder paste selection is a critical step toward flawless SMT manufacturing. At PCBCart, we're dedicated to making your PCB assembly easier with professional advice and integrated solutions. Start selecting solder paste with confidence and take your electronic assemblies to new levels of quality and efficiency.

Request for High-quality PCB Assembly & Fabrication Quote