The bare printed circuit board (PCB) is the fundamental component of a printed circuit board, constituting the structural substrate upon which the surface mount technology (SMT) components like resistors, capacitors, and integrated circuits are mounted and connected. The plainness and simplicity of such boards facilitate technicians to perform a variety of tests to check compliance with the intended design of the PCB, enabling early detection and fixing of any potential design deficiencies.

Typically, constructed of a non-conductive base material like FR4—a fiberglass-reinforced epoxy laminate—bare PCBs possess structural integrity. Copper foil in thin sheets laminated on to them provides conductive pathways for interconnections between devices. Well-designed and typically multi-layered, they are required to contain intricate circuitry and provide functionality, particularly in high-density applications critical to consumer electronics through to automotive and telecommunications industries.

Bare boards are a staple of modern technology, impacting everything from cell phones to automobiles. Their quality and construction are instrumental in delivering stable, high-performance operation, facilitating the seamless function of numerous electronic systems that are a part of daily life.

What is a Bare Board?

A bare board PCB is an electronic printed circuit board minus the electronic components, essentially the framework of a typical PCB before component mounting. Constructed of a non-conductive substrate material, usually FR4, bare boards consist of metal coatings, conductive pathways, and designs. Their fabrication includes processes like photo-resist lamination, etching, drilling, application of solder mask, and silkscreen printing.

They are also known as bare PCBs, blank PCBs, or PCBs in the industry, but when populated with components, they are called PCB assemblies (PCBAs).

Naked boards offer electrical and mechanical support to the production of circuits. Due to their versatility and flexibility, they are amenable to high-volume production in configurations ranging from the simple single-layer to complex multi-layered configurations, as required by high-density electronic systems. Advances in production processes like laser direct structuring and microvia drilling have increased their accuracy and capability, establishing their key role in applications ranging from consumer electronics to aerospace.

Industry standards, specifically IPC-2221, offer detailed guidelines to enhance design, fabrication, and quality assurance uniformity, cultivating the reliability and performance requirement of the contemporary technological age.

What is a Zero PCB?

Since we are talking about bare boards, a linked term called zero PCB enters the scene, stealing attention as its multi-purpose counterpart. A zero PCB is not made for any specific application but is a general-purpose, multi-purpose board. It is made up of tiny holes in a grid pattern, with each hole being electrically isolated.

Zero PCBs are valuable in prototyping circuit designs by offering a low-cost vehicle to try out circuitry before finalizing a solution. The "zero" in zero PCB is indicative of the fact that there are no predefined connections or functions on the board. Zero PCB is a PCB on which custom circuits are built using copper traces or pads that act as conductive paths to solder components. Unlike normal PCBs, zero PCBs lack solder masks or silkscreen and are intentionally plain to give users as much freedom as possible to design their own circuits without restrictions.

Basic Components of Bare Boards

A bare board, while simple in makeup, is the backbone of any complex PCB, keeping all the essential components in place. Key components include:

Substrate: Provides mechanical support and electrical insulation, typically made of FR4 as a compromise between strength and heat resistance. Special applications employ other materials like polyimide or ceramic composites.

Copper Traces: Etched conductive pathways serving as electrical signal highways. Their size dictates current capacity and signal integrity, with technology allowing narrower traces for improved performance.

Vias: As interlayer connections, vias come in types such as through-hole vias, blind vias, and buried vias, which are constructed from materials such as copper plating for longevity.

In zero PCBs, the copper traces or pads are unconnected and provide point-to-point wiring, such as on a breadboard, with the benefit of flexibility to prototype custom circuits.

When to Use a Bare Board

Bare boards can be established for design, concept, and functionality testing before assembling expensive components on a PCB. Their supportive role in PCB fabrications makes them vital in electronic productions, as they help identify potential flaws early in the design stage, thus having an impact on the usability of the end electronic device.

Advantages of Bare Board

The primary advantages of bare boards are:

Early Detection of Defects: Without the components, it is easier to judge the layout and design of the board, making it easier to find and correct defects.

Cost Savings: Early detection of defects prevents expensive repairs and the incorrect assembly of pricey components.

Time Savings: Prototyping improves the functionality guarantee, preventing time wastage on PCBs that do not function with a faster process to offset any time spent upfront.

While there can be potential accuracy and orientation errors during production or issues like etching errors that can result in critical defects, rigorous inspections ensure error-free boards before component assembly. Therefore, bare board testing ensures quality with minimal disadvantages.

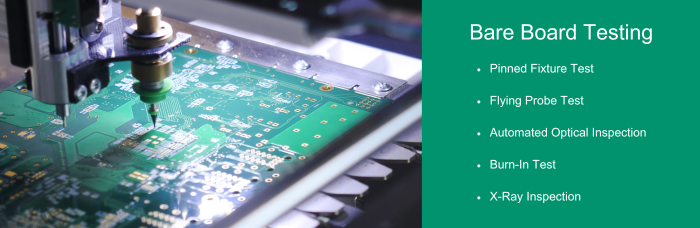

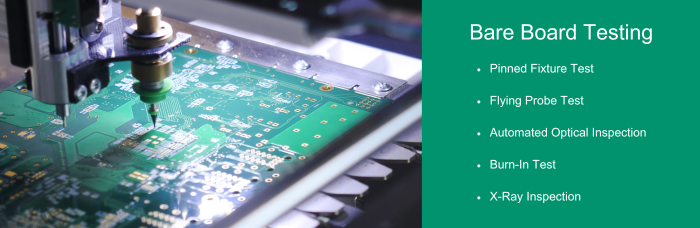

What is Bare Board Testing?

Bare board testing is an electrical test of the bare board to check for connectivity and insulation integrity. Continuity checking tests open circuits that would be a compromise on function, while isolation testing checks for resistance between alternate electrical connections, making electrical design compatible.

This kind of testing at early phases in manufacturing detects errors, which ensures reliability, especially required for the closely-packed PCBs of today's electronics.

Types of Bare Board Testing

Old-time testing with digital multimeters, though replaced in the situation of complex designs, has been replaced by many modern methods:

Pinned Fixture Test: Also known as Bed of Nails or In-Circuit testing, suitable for mass production, this quick test uses spring probes on a specially developed pin fixture. Although it is costly and has fixed setups, its effectiveness cannot be surpassed.

Flying Probe Test: Employing robot arms with poles to test each board connection, this inexpensive and flexible method is ideal for low-volume production but has longer testing times.

Automated Optical Inspection (AOI): Cameras capture images of boards to compare to schematics. It supports early fault detection, though combined testing is recommended for non-intrusive fail-safe.

Burn-In Test: Destructive but typical test defines load capacity and early defect detection through operation of power at high conditions for extended durations.

X-Ray Inspection: Ideal for internal inspection, discovering concealed soldering or connection faults early in the production process, assuring quality from the start.

Applications of Bare Boards in Engineering

Bare boards have several uses in engineering. The key areas are:

Automotive Industry

In modern automobiles, bare boards allow:

Engine Control: Essential functions in ECUs for fuel and emissions control.

Driver Assistance: Supports ADAS capability through sensor data processing.

Infotainment: Manages high-speed data in entertainment systems.

Thermal Management: Implements cooling systems for component longevity.

Telecommunications and Networking

Key in communication infrastructure like routers, switches, and base stations, they:

Ensure high-speed data integrity.

Reduce RF interference.

Use high-frequency materials suitable for harsh environments.

Consumer Electronics

Essential in products like smartphones and wearables, bare boards:

Apply HDI technology for miniaturization of components.

Accommodate flexible designs for wearables.

Challenges and Considerations

Challenges are:

Manufacturing Defects

Issues like delamination, shorts, and opens require processes like AOI, X-ray, and ICT for resolution.

Reliability and Longevity

Testing mimics operating stresses (thermal cycling, vibration), with emphasis placed on FMEA for reliability in high-reliability applications.

Cost Factors

Material choice, complexity, and methods influence costs. Economies of scale and strict inspection favor economical production.

Bare boards and zero PCBs are fundamental to bridging the gap between electronic design and physical implementation. They play a significant role in various high-tech areas, from automobiles to aviation, telecommunications, consumer electronics, and more. With the expansion of materials, design practices, and manufacturing technologies, these ubiquitous boards continue to stretch the boundaries of technological advancements to meet the increasingly demanding performance and reliability needs of modern electronics.

At PCBCart, we understand the vital role that bare boards play in the electronics industry. These basic building blocks are irreplaceable across industries like automotive and telecommunications, allowing devices to function reliably and efficiently. With technology developments continuing to push ahead, the demand for quality bare boards only gets more significant.

We are proud to offer top-level bare board solutions that are tailored to your specific requirements, from prototype through full production. Our commitment to accuracy and quality ensures sound performance for complex electronic systems. Let us be the solid foundation that your innovations require. Contact PCBCart today to obtain a quote and witness our dedication to excellence firsthand.

Get Your Bare PCB Quote Now

Helpful Resources

• What Type of PCB Substrate Material Is Right for Your PCB - Part One

• What Type of PCB Substrate Material Is Right for Your PCB - Part Two

• PCBCart Offers Professioanl Custom PCB Manufacturing Service - Starts from 1pc

• PCBCart Offers Turnkey PCB Assembly (PCBA) Service - 100% Quality Guaranteed

• Requirements on PCB Design Files for An Efficient Production