With the constant speed of technology today, the demand for small and high-performance components in electronic devices is increasing. Ball Grid Array (BGA) packages have emerged as a cornerstone in the realm of modern electronics due to their unparalleled connection density, improved thermal performance, and enhanced electrical characteristics. This article discusses the various types of BGA packages, highlighting their unique features and applications.

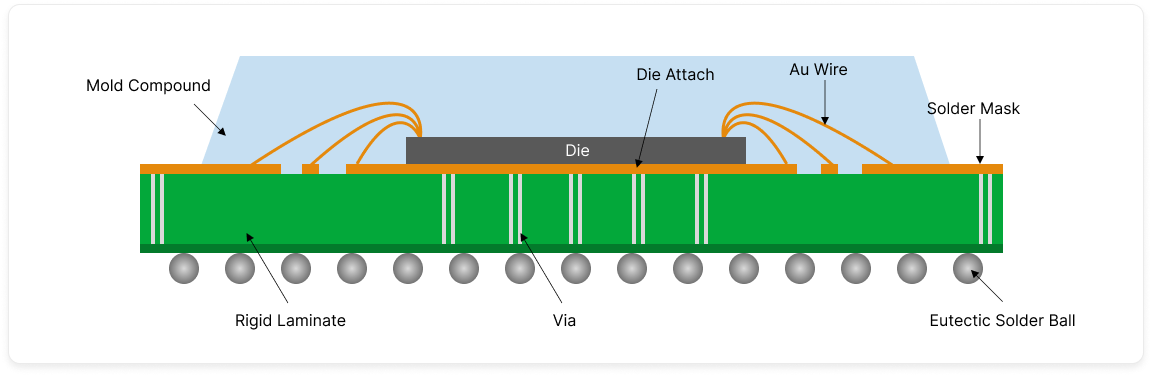

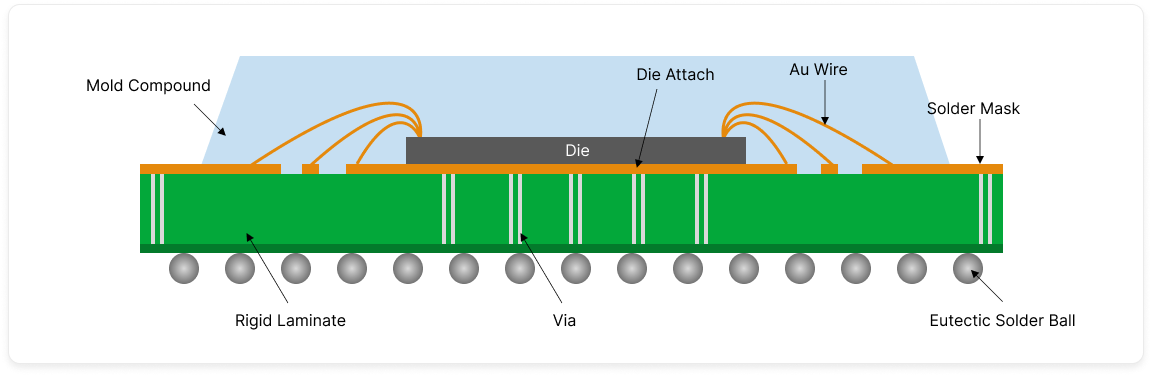

Ball Grid Array (BGA) is an integrated circuit (IC) surface-mount package. It is an array of small, round solder balls in a grid on the package's back. The balls are employed to establish electrical contact with a printed circuit board (PCB). Unlike traditional quad flat packages (QFP), which utilize the perimeter for contact, BGAs utilize the entire package area. This is a design that gives higher connectivity, improved electrical performance, and significantly better thermal management.

BGAs are popular because they offer a range of advantages over competing packaging technologies:

Thermal Management: BGAs are highly effective in heat dissipation. This is crucial in present-day electronic products, as heat can lead to severe degradation of performance and lifespan. By lowering the core temperature at peak operation, BGAs are critical to extending the life of a product.

Electrical Performance: With lower resistive losses due to shorter, more direct signal paths, BGAs enhance signal integrity. This results in improved performance, especially in high-frequency applications.

Space Utilization: With the utilization of the entire package footprint, BGAs are able to accommodate a higher pin count without a larger package size. It is a characteristic that is priceless in the miniaturization trend prevalent in today's electronic design.

Types of BGA Packages

Plastic Ball Grid Array (PBGA)

One of the most frequently used BGA types is the PBGA due to its price competitiveness and dependability in terms of performance. The package utilizes a plastic laminate substrate, mostly bismaleimide triazine (BT) resin. Ball counts from 200 up to 500 make PBGAs suitable for a broad group of applications and are mainly deployed in consumer appliances and communication technology. Low-cost production and frequency of usage have made them the darling of mid-power applications.

Ceramic Ball Grid Arrays

Ceramic Ball Grid Arrays are used in applications that demand high thermal and mechanical stability. Having a ceramic substrate and higher thermal conductivity, CBGAs provide superior performance over the plastic versions. While more costly, their reliability in telecommunication and high-performance computing applications justifies the added cost. The 10:90 tin-to-lead solder content and high melting point necessitate the Controlled Collapse Chip Connection (C4) means of connectivity.

Tape Ball Grid Array (TBGA)

TBGA improves the traditional BGA by using a tape substrate, which is flexible in nature and allows for thinner and lighter packaging without compromising connection density and performance. They are therefore most appropriate for portable and high-performance electronic devices. TBGA is highly esteemed in high-performance computing markets, where space and weight limitations become paramount to design.

Flip-Chip Ball Grid Array (FCBGA)

The FCBGA is special in that it turns the semiconductor die upside down, with solder ball direct connection to the PCB. This eliminates the need for leads and hence encourages high-density connections and superior electrical performance. FCBGAs possess short electrical paths and are therefore highly commended for their high conductivity and performance speed. They are used in the large majority of high-speed and high-frequency applications like integrated graphics processing and networking equipment.

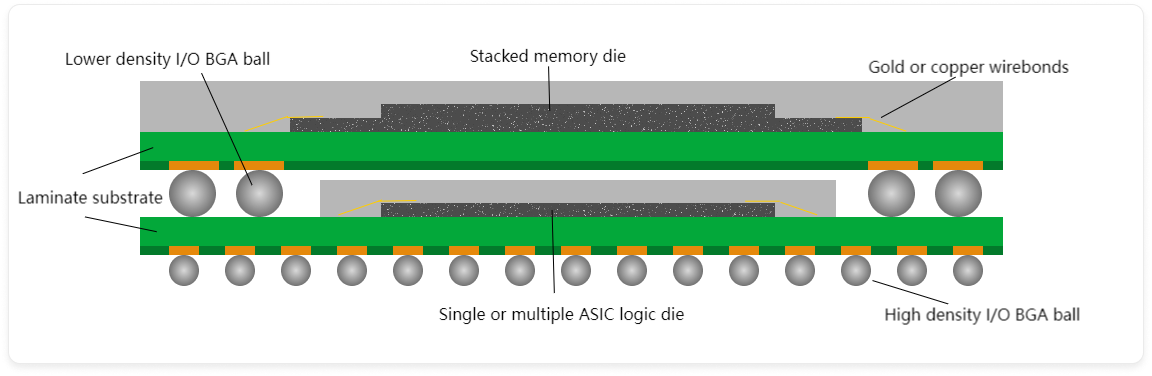

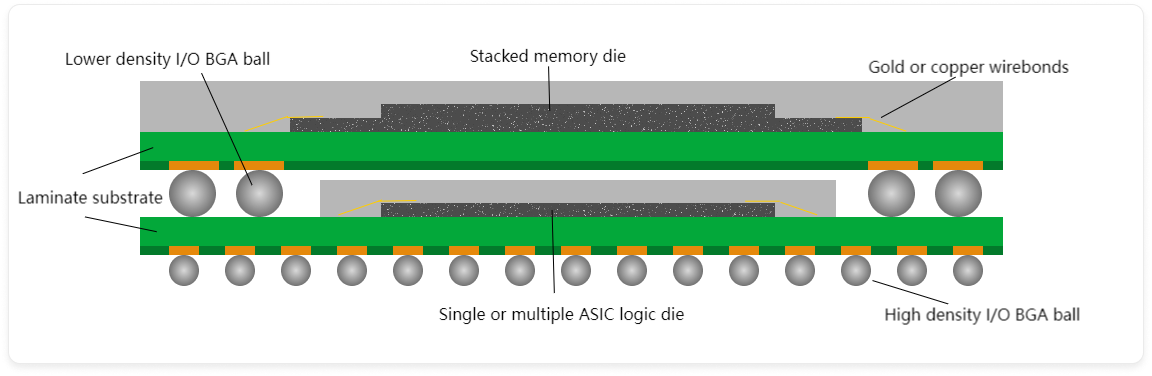

Package on Package (PoP)

PoP uses a vertical stack of multiple ICs, with each one containing its BGA. This helps meet the rising demand for electronic devices with compact size and high functionality. At the time of PCB assembly, PoP allows memory and logic devices to be electrically joined separately, resulting in modularity and easy replacement at less expense and complexity. It is specifically useful in space-constrained applications like digital cameras and smartphones.

Micro BGA

Because the technology has to be made smaller without reducing its performance, Micro BGAs are more sought after. Micro BGAs, which are designed by companies like Tessera, can pack tremendous technological ability in very small space, with solder balls as small as possible and reduced overall dimensions. Micro BGAs are employed by manufacturers to create high-tech but small products, so they are very critical in areas like mobile computing and sophisticated IoT devices.

Metal Ball Grid Array (MBGA)

MBGAs employ metal substrates, which provide better electrical performance and improved thermal conductivity. The mechanical strength and ability to dissipate heat effectively make them suitable for applications where mechanical strength is of utmost importance, such as aerospace and automotive industries. Employing metal ceramics provides a distinct advantage in thermal and mechanical reliability.

In today's more digital world, where the trend for smaller, faster, and more reliable equipment goes on incessantly, BGA technology plays a central role. Knowing the vast array of choices at hand and their respective advantages allows manufacturers to make wise decisions that are balanced in terms of performance, reliability, and expense. The meticulous selection optimizes the creation of reliable and efficient electronic devices in accordance with advancing technology and demand in the market.

As you plan your next manufacturing endeavor, consider the role of Ball Grid Arrays in the electronics of today. Their development and growth are set to unlock a frontier of innovation, driving the world of electronics toward an increasingly integrated and powerful future.

The selection of the right Ball Grid Array (BGA) package is crucial to achieving the best balance between space efficiency, thermal performance, and electrical performance in electronic products of today. By being aware of the specific strengths and applications of every BGA type—from the popular PBGA and CBGA to the advanced PoP and Micro BGA—designers have good decisions that render their products stronger and more efficient. At PCBCart, we offer professional services and the best facilities to assist you in applying the most suitable BGA solutions for your intention. Ask about our quote for your PCB BGA assembly needs and see firsthand our commitment to quality and excellence. Let us assist in making your designs come to life with precision and excellence.

Request the Detailed BGA Assembly Quote for Your Project

Helpful Resources

• SMT, Surface Mount Technology Assembly | PCBCart

• Four Steps to Know BGA | PCBCart

• PCB Design Elements Influencing SMT Manufacturing

• An Introduction to BGA Package | PCBCart

• Instruction on Getting Free PCB Assembly Quotes