Thermal performance has been a primary concern for engineers in PCB design and fabrication and PCB substrate materials with high thermal conductivity play a significant role in improving the thermal performance of PCBs. Based on this fundamental principle, this article mainly introduces a manufacturing method for PCB substrate materials with high thermal conductivity. Through experiment, it can be testified that thermal conductivity can reach 3w/m•k at least with excellent insulation and reliable performance.

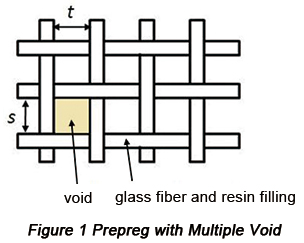

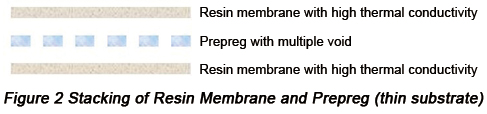

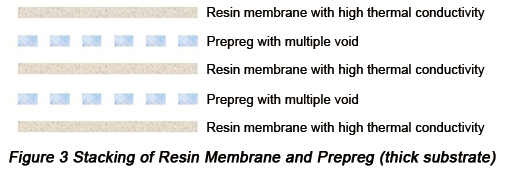

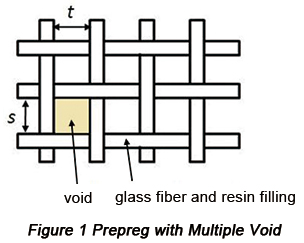

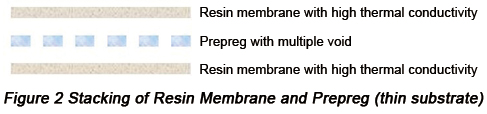

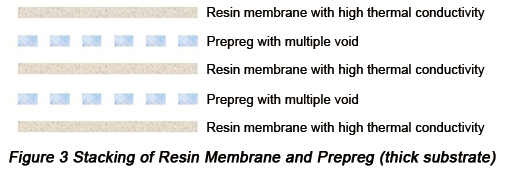

This manufacturing method of PCB substrate materials with high thermal conductivity relies on alternate stacking of prepreg with multiple voids and resin membrane with high thermal conductivity prior to copper foil coating. In the process of heating stacking, voids on prepreg are filled with resin composite with high thermal conductivity and become solid so that PCB substrate material with high thermal conductivity is obtained with excellent insulation and reliable performance and mechanical strength of substrate maintained, as is shown in Figure 1 to Figure 3 below.

• Prepreg of glass fiber substrate with multiple voids

Multiple voids refer to the fact that voids exist between warp and weft that aren't occupied by impregnating resin, which is called void ratio, hereby conforming to formula (1):

X = Y/(s*t)

In this formula, X refers to void ratio; Y refers to the area formed by warp and weft that is not filled by resin; s and t refer to side length.

Based on Formula (1) and Figure 1, it can be concluded that X should be enlarged in order to improve thermal conductivity and its value is usually 0.3 or more and it's better to get its value to be 0.5 or more, which depends on weaving structure of glass fiber cloth and is correlated with impregnation technology as well.

Either glass fiber cloth or organic fiber cloth can be applied and for the former, it's better that the diameter of glass fiber is in the range from 6-9μm.

Resin applied by impregnation glass fiber cloth comes primarily in epoxy resin such as bisphenol type A epoxy resin, bisphenol type F epoxy resion, bisphenol type S epoxy resin etc. With the improvement of heat withstanding performance and electrical performance considered, phenolic novolac type epoxy resin, bisphenol A novolac type epoxy resin and cycloaliphatic epoxy resin can be applied and for flame retardant epoxy resin containing bromine can be applied. These resins can be applied independently or jointly by two types or more.

Curing agent for epoxy resin come primarily in phenol type compound, amine type compound and cyanate ester type compound, which can be applied independently or jointly by two types or more. The amount is generally 0.1% to 5% of the overall amount of resin.

In this experiment, the applied curing catalytic agent is mainly 4-Methyl-2-ethylimidazole, 2-Ethyl-4-Methyl 1-H-imidazole-1-propanenitrile etc., which can be applied independently or jointly by two or more types. The amount is generally 0.001% to 0.01% of the overall amount of resin compound.

Resin solution is actually mixture of epoxy resin, curing agent and catalytic agent, coupled with organic solution, applied to impregnate glass fiber cloth. Glass fiber cloth will be dried for 2 to 15 minutes at the temperature of 120°C to 170°C after impregnation, becoming prepreg with multiple voids with thickness of 0.04mm to 0.3mm. Resin content of this prepreg is generally 30% above.

• Resin membrane with high thermal conductivity

This is a type of resin membrane with inorganic filler with high thermal conductivity added to thermosetting. Applied resin is actually the system of resin and curing agent of prepreg with multiple voids. Inorganic filler features multiple categories and specs. For example, aluminium oxide (Al2O3) powder, aluminium nitride (AlN) powder, silicon dioxide (SiO2) powder, silicon nitride (SiN) powder and boron nitride (BN) powder perform high thermal conductivity and organic filler with excellent insulation can be applied as well. Aluminium oxide (Al2O3) powder is greatly suitable for the application in this aspect and oxidation treatment can be implemented to powder if it is applied so that oxide film is formed at the surface of powder particles, which is beneficial to the improvement of wet resistance of products.

In order to improve bond property between inorganic filler and organic resin, coupling agent treatment has to be implemented to filler.

Fillers mentioned above can be applied both independently and jointly. In resin compounds, applied amount of inorganic filler is in the range from 60% to 95%; lower than 60%, effect will be less obvious while higher than 95%, formation will be difficult and performance of products fails to be obtained.

In order to mix multiple composites of resin evenly, blender and ball mill are generally applied for treatment.

With resin mixtures coated on metal foil or plastic membrane, resin membrane with high thermal conductivity can be obtained after heating and drying whose thickness is in the range from 0.04mm to 0.3mm.

• Copper foil coating stacking board with high thermal conductivity

Glass fiber cloth substrate prepregs with multiple voids and resin membrane with high thermal conductivity are stacked up according to Figure 2 and 3 prior to copper foil coating. Stacking is implemented for 60 to 120 minutes at the temperature of 160°C to 180°C and a pressure of 2 to 4MPa.

Finally, with copper foil coating board with high thermal conductivity, glass fiber cloth prepregs with multiple voids, resin membrane with high thermal conductivity and copper foil, multi-layer PCBs with tremendous thermal conductivity can be fabricated based on manufacturing technology of multi-layer PCBs.