When the thermal heat dissipation requirements of a design are very high, using an Aluminum backed PCB is a highly effective solution. This kind of design is capable to better translate thermal energy away from your design's components, therefore control your project's temperature. It is typically on the order of ten times more efficient at removing thermal energy from circuit components than the equivalent fiberglass backed board. This significantly higher level of thermal dissipation allows for higher power and higher density designs to be implemented.

Moreover, Aluminum Backed PCBs are finding applications in high power/high thermal heat dissipation applications. Originally tasked for use in high power switching supply applications, they have become very popular in LED applications. Examples of LED applications include traffic lights, general lighting and automotive lighting. The use of an aluminum backed design (LED PCBs) allows for a higher density of LEDs in the board design and for the mounted LEDs to be driven at higher currents while still remaining within temperature tolerances. Using an Aluminum backed design can allow designers to decrease the safety margin used with power LEDs and derate said LEDs less than would be the case with a conventional PCB design. As with all components, the lower the operating temperature of the LEDs in a design the longer those LEDs can be expected to operate before failing.

Other applications for Aluminum backed PCB designs include high current circuitry, power supplies, motor controllers and automotive applications. Aluminum backed PCBs are the perfect thermal heat dissipation solution for any design that utilizes high power surface mount ICs. Additionally, they can eliminate the need for forced air and heat sinking, then ultimately lower design cost. Essentially, any design that can be improved by higher thermal conduction and better temperature control is a possible application for an Aluminum backed PCB.

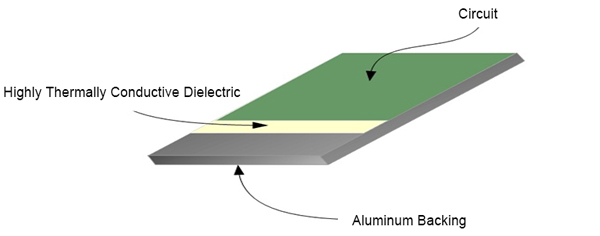

Where as traditional PCBs use fiber glass substrates (FR4 is the standard substrate used by PCB fabricators), Aluminum backed PCBs are composed of an aluminum backing, a highly thermally conductive dielectric layer and a standard circuit layer. The circuit layer is essentially a thin PCB that has been bonded to the aluminum backing layer. As such, the circuit layer can be as complex as those mounted on traditional fiber glass backing.

While it is much more common to see single sided designs, it's also possible for an aluminum backed designs to be two sided, with a circuit layer attached through highly thermally conductive dielectric layer on both sides of an aluminum backing. These two sided designs can then be connected by way of plated through holes. Regardless of the configuration the aluminum backing provides an excellent thermal path way to the surrounding environment or any attached heat sink. Once again, improving thermal conduction from power components is the best way to ensure the reliability of your design and aluminum backed PCB offers an excellent solution to this issue.

The solder mask layer of the circuit portion of the board can be made a number of different colors as in traditional PCB designs. That said, in LED designs the solder mask layer is typically white. A white solder mask allows for a higher level of light reflection from the associated LED array and produces a more efficient design. The solder mask is also commonly made black in power designs to better radiate heat.

Aluminum backed PCB designs are also highly mechanically stable and lend themselves to use in applications that require a high level of mechanical stability or are subject to a great deal of mechanical stress. What's more, they are less subject to thermal expansion when compared with fiberglass based constructions. If your design doesn't require high levels of thermal conduction, but the board will be subject to a great deal of mechanical stress or has very tight dimensional tolerances and will be subject to a great deal of heat, the use of an aluminum backed design may be warranted.

Finally, aluminum is not the metal backing material available. Copper and copper alloys, though not as popular due to their typically higher cost, are also used as a backing material. Copper and copper alloys offer an even higher level of performance with regards to thermal heat dissipation than aluminum. As such, if a standard aluminum backed design isn't meeting the thermal heat dissipation demands of a design, using copper can be considered as a next step in resolving the issue.

In conclusion, using an aluminum backed solution can go a long way towards increasing the reliability and life time of a design through temperature control and the resultant low component failure rates. Along with excellent temperature control characteristics, aluminum designs also provide high levels of mechanical stability and low levels of thermal expansion. When standard fiberglass (FR-4) backed PCBs cannot satisfy the thermal dissipation and density requirements of your design, aluminum backed PCBs may provide the answer.