PCB successfully added to your shopping cart

A Comprehensive Introduction of Copper Clad Laminate

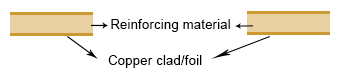

Copper Clad Laminate, abbreviated to CCL, is a type of base material of PCBs. With glass fiber or wood pulp paper as reinforcing material, a copper clad board is a type of product through lamination with copper clad on either one side or both sides of reinforcing material after being soaked in resin.

How are CCLs Classified?

According to different classification standards, CCLs can be classified into various categories:

• Based on CCL mechanical rigidity, we have rigid CCL (FR-4, CEM-1, etc.) and flex CCL. Rigid PCBs depend on rigid CCLs while flex PCBs are on flex CCLs (flex-rigid PCBs are on both rigid CCLs and flex CCLs).

• Based on insulation material and structures, we have organic resin CCL (FR-4, CEM-3, etc.), metal-base CCL, ceramic-base CCL etc.

• Based on CCL thickness, we have standard thickness CCL and thin CCL. The former one requires at least 0.5mm thickness while the latter can be thinner than 0.5mm. Copper foil thickness is excluded from CCL thickness.

• Based on reinforcing material types, we have glass fiber cloth base CCL (FR-4, FR-5), paper base CCL (XPC), compound CCL (CEM-1, CEM-3).

• Based on applied insulation resin, we have epoxy resin CCL (FR-4, CEM-3) and Phenolic CCL (FR-1, XPC).

What Makes an Excellent CCL?

CCLs only perform well when catering to performance requirements in the following aspects:

• Appearance. Issues may be caused on copper foil due to unexpected elements in manufacturing process such as dent, scratch, resin point, wrinkle, pinhole, bubble etc. All those problems will definitely lead to low performance of CCL and then PCB. Therefore, an excellent CCL should be flat and smooth in appearance.

• Size. Since CCLs are base material of PCB boards, they have to conform to size requirements corresponding to PCBs. Parameters concerning the size of CCLs include length, width, diagonal deviation and warpage, each of which has to meet specific requirement.

• Electric performance. This is an essential mission for a PCB so any aspect affecting its electric performance has to be carefully designed including dielectric constant (Dk), dielectric loss tangent (Df), volume resistance, surface resistance, insulation resistance, arc resistance, dielectric breakdown voltage, electric strength, Comparative Tracking Index (CTI) etc.

• Physical performance. Parameters concerning physical performance of a CCL include dimensional stability, peel strength (PS), bending strength, heat resistance (including thermal stress, Td, T260, T288, T300), punching quality etc.

• Chemical performance. Chemical performance of a CCL has to meet the requirements of flammability, chemical reagents resistance, Tg, Z-axis coefficient of thermal expansion (Z-CTE), dimensional stability etc.

• Environmental performance. It has to cater to the requirements in terms of water absorption etc.

CCL quality judgement should be carried out by PCB Fab Houses. Take PCBCart for example, it applies IPC-4101C as a manufacturing standard and uses IPC-TM-650 for CCL testing. Accordingly, such measures lead CCLs to be qualified substrate of PCBs.

What is Prepreg?

Prepreg, the reinforcing material inside a CCL, is made from glass fiber after being baked. It is also called bonding sheet by some people and composed by epoxy resin, glass fiber cloth, DMF, 2MI, acetone etc.

• Classification of Prepreg. Prepreg can be classified into many categories based on different classification standards:

1). Based on glass fiber cloth: 106, 1080, 2112, 2116, 1500, 7628;

2). Based on applied resin and its performance: POLYCLAD Turbo 254/226, ISOLA FR402/FR406, ITEQ IT180, Sheng Yi S1141-140/170;

The following table shows PCBCart partial manufacturing capabilities in terms of prepreg. More detailed info please reach us at [email protected].

| Prepreg | Gel Time (s) | Resin Content | Thickness |

|---|---|---|---|

| 1080 | 135±15 | 62±1.5% | 3mil |

| 2112 (2113, 2313) | 135±15, 115±15 | 57±1.5%, 59.5%-62.0% | 4mil |

| 2116 | 135±15 | 49.5±1.0%, 53±1.5% | 5mil |

| 7268 | 113±15, 135±15 | 44±1.5%, 38±1.5%, 41±1.5% | 7mil |

• Classification of Resin

1) Phenolic resin

2) Epoxy resin

3) Polyimide resin

4) Polytetrafluorethelene resin (PTFE or TEFLON resin)

5) Bismaleimide triazine (BT)

• Attributes of Glass Fiber can be summarized into the following aspects:

1) High intensity

2) Heat and fire resistance

3) Humidity resistance

4) Excellent insulation capability

• Aspects affecting quality of prepreg. High-quality prepreg leads to high-quality CCLs, thereafter, PCB. Therefore, PCBCart pays much attention to test and control of prepreg quality, which is carried out in terms of resin content, gel time, resin fluidity, volatile content and dicyandiamide crystallization.

• Select prepreg based on cost. When it comes to the cost of prepreg, glass fiber cloth accounts for the majority of high cost. Generally speaking, the cost of prepreg is directly related with the thickness of glass fiber cloth. The thinner prepreg is, the higher the cost becomes. In addition, prepreg 2112 is more expensive than prepreg 1080 because the former is seldom applied.

What is Copper Foil?

Copper foil can be summarized into the following table according to technology and class.

| Class | Type | Name | Code |

|---|---|---|---|

| 1 | E | Standard electrodeposited | STD-Type E |

| 2 | E | High ductility electrodeposited | HD-Type E |

| 3 | E | High temperature elongation electrodeposited | HTE Type E |

| 4 | F | Annealed electrodeposited | ANN-Type E |

| 5 | W | As rolled-Wrought | AR Type W |

| 6 | W | Light cold rolled-Wrought | LCR Type W |

| 7 | W | Anneal-Wrought | ANN Type W |

| 8 | W | As rolled-Wrought low-temperature annealable | ARLT Type W |

In accordance with performance, copper foil can be classified into standard copper foil that is applied for FR-4 and paper base board, HTE that is applied for multi-layer PCBs to feed back split ring issue and low profile (LP) copper foil that is applied for multi-layer PCBs as well.

New Trend of CCL

In order to cater to the regulations of RoHS (Restriction of Hazardous Substances), higher requirements are brought on CCLs in terms of heat resistance and reliability. Modifications are implemented from the following two aspects:

• Halogen-free CCL. It refers to CCLs whose content of chlorine (Cl) and bromine (Br) is controlled within 900ppm while their overall content is no more than 1500ppm. Performance comparison between halogen-free CCLs and ordinary FR-4 CCLs is summarized into the following table.

| Item | Halogen-free CCLs | FR-4 CCLs |

|---|---|---|

| Flammability | V-0 | V-0 |

| Peel strength | Bad | Good |

| Heat performance | Good | Bad |

| Thermal decomposition | >320°C | 310°C |

| Size stability | Excellent | Bad |

| T260 | >30min | 10min |

| Bending strength | Bad | Good |

• Lead-free CCL. It refers to copper clad PCBs whose surface mounting is carried out without the application of lead-free solder. The main resin of lead-free CCLs is brominated epoxy resin. According to the regulations of RoHS, six substances such as PBB and PBDE are no longer used in CCLs. Compared with DICY curing system (with dicyandiamide as curing agent) applied in ordinary FR-4 CCLs, lead-free CCLs take advantage of PN curing system (with Phenol-formaldehyde resin as curing agent).

| Item | DICY | PN |

|---|---|---|

| Peel strength | Good | Bad |

| Thermal performance | Bad | Good |

| CAF resistance | Bad | Good |

| Thermal decomposition temperature | 310°C | >320°C |

| Water absorption resistance | Bad | Good |

| T260 | 10min | >30min |

| Bending strength | Good | Bad |

Standards in terms of peel strength on halogen-free CCLs and lead-free CCLs have been accepted by PCB and CCL industries.

| Specification | IPC Standard | Attributes | ||

|---|---|---|---|---|

| 1 b/in | Kg/cm | LF/HF typical value | ||

| 12μm | / | >5 | >0.9 | / |

| 18μm | / | >6 | >1.05 | 1.15Kg/cm |

| 35μm | >1.05N/mm | >8 | >1.4 | 1.5Kg/cm |

| 70μm | / | >11 | >2.0 | / |

Due to more than two decades' efforts and experience, PCBCart has been playing an active role in contributing to the flourishing of this business. Certified by ISO 9001, UL and RoHS, it is fully capable of providing high-quality and environmental-friendly PCBs with corresponding type of copper clad PCB boards at competitive prices.

Good-quality CCLs ensure good PCB performance through compliance with standards in appearance, size, and electric, physical, and chemical properties. Prepreg, the primary material in CCLs, is the origin of the quality of CCLs. As one of the global leading PCB manufacturers, PCBCart provides great, eco-friendly PCBs. For superior PCB solutions, partner with PCBCart. Request your free quote today!