PCB successfully added to your shopping cart

5 "Whats" about FR-4 Copper Clad Laminates

Among the fiberglass cloth base CCL products, FR-4 CCL refers to a type of flame-retardant CCL with fiberglass cloth as its substrate material and with brominated epoxy resin or modified epoxy resin as its adhesive.

Through holes in substrate can be metalized, also called plated through hole so that circuit conductivity can be implemented between layers in double-layer or multi-layer PCBs due to the features of fiberglass cloth base CCLs including high strength, excellent thermal resistance, and high dielectric properties. Recent years have witnessed higher requirement of thermal resistance for substrates with the updating and upgrading of electronic products so that some of paper base CCL products have been gradually replaced by fiberglass base CCLs. As a result, FR-4 fiberglass base CCLs have upgraded into the category of the most massive utilization and quantity among all products based on CCLs.

What are attributes of FR-4 CCL?

Products based on FR-4 CCL gained massive utilizations and the largest quantity among all fiberglass cloth base CCLs owing to its advantages:

• PCB manufacturability;

• CCL manufacturability;

• Excellent electric insulativity;

• Flame retardancy;

• Plentiful source;

What are products based on FR-4 CCL?

Up to now, different products based on FR-4 CCL have been generated and developed due to different performance levels and the categories are undertaking gradual generation and development. The main products based on FR-4 CCL are displayed in the content below:

• Common FR-4: flame retardant fiberglass cloth substrate as substrate material, flame retardant brominated epoxy resin as adhesive.

• Mid-Tg FR-4: flame retardant fiberglass cloth substrate as substrate material, brominated epoxy resin with excellent flame retardancy as adhesive.

• High-Tg FR-4: flame retardant fiberglass cloth substrate as substrate material, brominated epoxy resin with better flame retardancy as adhesive.

• Lead-free soldering FR-4: flame retardant fiberglass cloth substrate as substrate material and brominated epoxy resin with excellent flame retardancy as adhesive. Due to high soldering temperature of lead-free solder, much higher requirements must be met by thermal decomposition of substrate.

• Halogen-free FR-4: flame retardant fiberglass cloth substrate as substrate material, flame retardant phosphating nitriding epoxy resin as adhesive.

• Mid-Tg (Tg150°C) halogen-free FR-4: flame retardant fiberglass cloth substrate as substrate material, phosphating nitriding epoxy resin with excellent flame retardancy as adhesive.

• High-Tg (Tg170°C) halogen-free FR-4: flame retardant fiberglass cloth substrate as substrate material, phosphating nitriding epoxy resin with better flame retardancy as adhesive.

• FR-4 CCL with high performance: flame retardant or non flame-retardant fiberglass substrate. This type of CCL features high thermal resistance and characteristic attributes, using fiberglass cloth as substrate material and using modified epoxy resin with extremely excellent thermal resistance, triazine/bismaleimide resin, polyimide resin, PPE resin, diphenyl ether resin, cyanate ester resin or polytetrafluoroethylene resin as adhesive.

• Prepreg: When fiberglass cloth substrate material is dipped into resin glue and then dried to Level B, prepreg is generated. It has two functions one of which is to be used for CCL manufacturing and the other of which is to be used as inner layer adhesive material in multi-layer printed circuit board manufacturing. Although it's not a type of CCL, it enjoys a large amount of sales.

• Additionally, there are High modulus FR-4 board, FR-4 board with low coefficient of thermal expansion, FR-4 board with low dielectric constant, High-CTI FR-4 board, High-CAF FR-4 board, High thermal-conductivity FR-4 board for LED.

What is the production process of FR-4 CCLs?

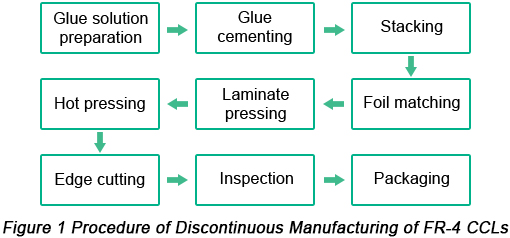

CCL manufacturing methods can be classified into two categories: discontinuous manufacturing and continuous manufacturing that is further classified into stacking process continuous manufacturing and continuous manufacturing from cementing to stacking. Up to now, discontinuous manufacturing accounts for most of manufacturing methods.

• Discontinuous manufacturing of FR-4 CCLs

Figure 1 shows procedure of discontinuous manufacturing of FR-4 CCLs. Each step of the procedure is implemented discontinuously.

• Continuous manufacturing of FR-4 CCLs

Since discontinuous manufacturing of FR-4 CCLs features a prominent disadvantage of low manufacturing efficiency and large material consumption, continuous manufacturing has been studied since a long time ago and new development has been generated. Continuous manufacturing of rigid boards is classified into two manufacturing methods: continuous stacking of CCLs and continuous manufacturing from glue cementing to stacking.

1). Continuous stacking manufacturing of FR-4 CCLs

This type of manufacturing is implemented through work of laminators. Continuous stacking manufacturing is relatively suitable for thin CCLs manufacturing because thin products have excellent thermal conductivity so that stacking time can be shrinked. Since the time of products' passing through laminators is relatively short, all the technological parameters of prepreg to be stacked are different from those of ordinary prepregs. Modification is essential for each item of technology of prepreg and resin ingredient.

2). Continuous glue cementing and stacking manufacturing of rigid CCLs

The continuous stacking manufacturing mentioned above is only applied in the run of stacking of the whole procedure. This type of manufacturing is available for each run of the whole procedure starting with glue cementing.

What is the first element of fantastic manufacturing of FR-4 CCLs?

Fantastic manufacturing of FR-4 CCLs derives from resin ingredient with reasonable ratios that is the prerequisite of excellent CCL products and electronic products. For CCL manufacturers, requirements of resin ingredient maintain the same after the determination of product models.

Traditional resin ingredient is displayed in the following table:

| Material Name | Ratio |

| Brominated epoxy resin | 100 (solid quantity) |

| Dimethyl formamide | 24-30 |

| Dicyandiamide | 2.3-3.5 |

| Accelerant (dimethylimidazole or benzylamine) | 0.05-0.15 |

| Solvent | Appropriate amount |

In this ingredient, the ratio means that all the data within the range are utilized by manufacturers. Differences in terms of distribution ratio of each group lead to differentiations in terms of craft and products. Therefore, it's necessary to test the ingredient before manufacturing in order to obtain the most suitable and reasonable ingredient. The keys to the successful resin ingredient include epoxy resin, curing agent, model and amount of accelerant.

This resin ingredient is suitable for both FR-4 CCLs and FR-4 laminate. The former enjoys relatively wide degree of freedom in terms of resin ingredient and manufacturing craft as a result of no requirement of copper foil peel strength and copper foil bubble quality.

Due to two decades' efforts and experience, PCBCart has been playing an active role in contributing to the flourishing of this business. Certified by ISO 9001, UL and RoHS, it is fully capable of providing high-quality PCBs with corresponding type of CCLs at competitive prices.