Lots of electronic parts are applied in modern automotive vehicles and the number of electronic control systems can exceed 250. When driving a car, it's easy for us to see the electronic control systems everywhere including under the baffle, around power supply control, in car cockpit or near steering wheel.

As far as automotive electronics is concerned, both electrical and electronic devices feature extremely complicated structures. Automotive electronic systems have to provide technical specifications to the largest extent and have to pass expanded stress test and reliability test procedure since all the automotive applications will have to be confronted with tests as a result of their applications in rigorous environment. Therefore, technical requirement and technical specifications of those electronic systems are determined by the thought of obtaining high reliability through such low cost, which calls for many more rigorous demands than ordinary rigid PCB (printed circuit board). Interconnection between PCBs has to be achieved and it has to be connected with peripheral equipment, all of which can be realized through the application of ordinary cables and electric wires, tape cable, jumpers, connectors etc. Nevertheless, during the test process concerning extended reliability, stress test and practical running on the road, it's low-quality solder joints and connectors that usually lead to electrical failure.

Merits of Flex-Rigid PCB Application in Automotives

To successfully solve the issue mentioned in the first paragraph, flex-rigid PCB is applied to reduce the number of connectors and solder joints, which has been conformed to for over 20 years. As flex-rigid PCB is applied in automotive systems, the following advantages can be embraced.

• Obvious Improvement of Product Quality and Reliability

When applying flex-rigid PCB for automotives, connectors and soldering joints can be reduced, which can decrease the potential risks leading to electrical failures. Performance and reliability of automotive electronics control systems will proportionally go up with the reduction of connectors and soldering joints.

• Cost Reduction Due to Manufacturing Steps Shrinking

As flex-rigid PCB is applied, soldering of tape cable and assembly connectors will be cut so that cost will go down. After all, all the manufacturing procedure implementation is costly.

• Maintenance Simplification and Elimination

Flex-rigid PCB for automotives is composed by two or more than two pieces of rigid materials and one or more than one piece of flexible material while rigid sections are connected with each other through the application of flexible materials. Each rigid-flex circuit can be accurately packaged into a smaller package so that lots of administration and maintenance will be eliminated.

• Designer and Assembly Freedom Improvement

Flex-rigid circuit designers are only responsible for rigid board layout. As for flexible section, they only need to lead the connection and are capable of freely fixing, slinging or piling, which dramatically eases design and assembly.

Up to now, two types of flex-rigid PCBs are available in current market:

a. Semi-flexible PCB. Flexible section of semi-flex PCB is made of thin FR-4 material, especially applicable for assembly calling for just a couple of flexibilities. Moreover, semi-flexible PCB leads to low cost.

b. Multi-flexible PCB. Made by polyimide (PI) material, multi-flexible PCB works agreeably on applications calling for dynamic flexibilities. Since PI layer can expands into internal rigid section of flex-rigid PCB, multi-flex circuit boards are more applicable for applications calling for gradually dynamic flexibilities.

Multi-Flexible PCB

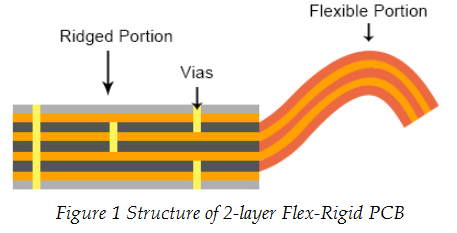

When the flexible section of flex-rigid PCB is made by flexible PI copper foil material, it belongs to multi-flexible PCB category. Belonging to a type of traditional flex-rigid PCB, multi-flexible PCB has been leveraged for more than three decades. Multi-flexible PCB features a hybrid structure laminated by rigid substrate material and flexible substrate material and interconnection between electrical conductors is achieved through electro-plated vias that will go through rigid and flexible materials. Figure 1 below demonstrates the structure of a two-layer flex-rigid circuit board.

In accordance with Figure 1, it can be concluded that flexible substrate material depends on ordinary PI copper foil material and it is not only laid in flexible section but covers all the rigid section as well. However, it's equivalently effective to lay some structures of PI copper foil in selective section. Since manufacturing complexity will go up once flexible PI copper foil is used in selective section, this method is seldom used generally.

When it comes to multi-layer flexible PCBs, because adhesive along Z-axis direction features relatively high CTE (coefficient of thermal expansion), the adhesive will possibly lead to mechanical damage of electro-plated via during stress test or thermal shock test. Therefore, when automotive PCB calls for higher thermal reliability, it's obligatory to avoid using flexible substrate material and cover lay within rigid section since electro-plated vias are usually available in rigid section.

Furthermore, temperature reliability issues have to be considered in terms of adhesive and no-flowing prepreg of ordinary FR4 because FR4 prepreg is also a type of substrate material with high CTE. No-flowing prepreg of ordinary FR4 features a Tg that is 105°C that is lower than that of traditional FR4 prepreg by approximately 30°C.

Apart from FR4 material that is used as rigid substrate material, almost any type of rigid material is applicable for multi-flexible PCB, including high-Tg material, halogen-free material or even high frequency material.

Majority of flexible materials for flex-rigid PCB use PI with adhesive or PI without adhesive that performs better. Nevertheless, PEN and PET material can be also used for simple and asymmetric flex-rigid circuit board structure. LCP (liquid crystalline polymer) material can be regarded as an optimal flexible material without adhesive with high reliability design and high-speed signal transmission design. It's suggested that they should be baked prior to their applications to eliminate humidity due to high humidity absorption of PI. Multi-flex PCB with LCP as substrate material, however, don't need to be baked.

As far as flex-rigid PCB is concerned, multi-flex circuits can allow a couple of flexible layers to be simultaneously available. Because complex interconnections of circuit are integrated designed, it can be repeatedly manufactured, which is advantageous than cable and wire connection. Thus, characteristic impedance control signal transmission line design can be implemented to replace coaxial cable.

Semi-Flexible PCB

Semi-flexible PCB fails to implement constant flexibilities. In fact, during many applications, the flexible portion of flex-rigid PCB only carries out a couple of flexibilities such as during assembly, rework and maintenance. Therefore, expensive flexible material like PI isn't necessary for such applications and bendable material is used, which is sufficient. Plus, cost can be reduced. Semi-flexible PCB can take advantage of traditional substrate material for multi-layer lamination so that different materials will be avoided being laminated together with internal thermal stress being the minimum. To acquire flexible material, the optimal method lies in getting traditional FR4 substrate material to be enough to be bent. Of course, another method is that the thickness of flexible portion should be selectively reduced.

Semi-flexible PCB is fabricated by sticking to the same manufacturing technology with traditional double-sided PCB and multi-layer PCB. Flexible portion thinning can be done through milling. Moreover, semi-flexible PCB is fabricated by sticking to similar manufacturing technology of traditional PCB except that flexibility manufacturing is added to it.

Reach PCBCart for Cost-effective Flex-rigid PCB Manufacturing Demands

PCBCart has been offering flex-rigid printed circuit boards manufacturing service since 2005. We have all it takes to print fully functional PCBs within customer required lead time and budget. Feel free to reach us to discuss your flex-rigid PCB fabrication and assembly demands or click below button to request PCB quote.

Request Flexible PCB Quote

Helpful Resources

• Flex-rigid Printed Circuit Board Applications

• Streamline Assembly and Improve Reliability with Flexible and Flex-rigid PCBs

• Flex-rigid PCB Manufacturing Services from PCBCart

• PCBCart Offers Flex-rigid PCB Assembly Services

• Applications and Types of PCBs for Automotive Industry