PCBCart Team

Sept 23rd, 2025

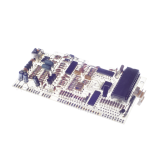

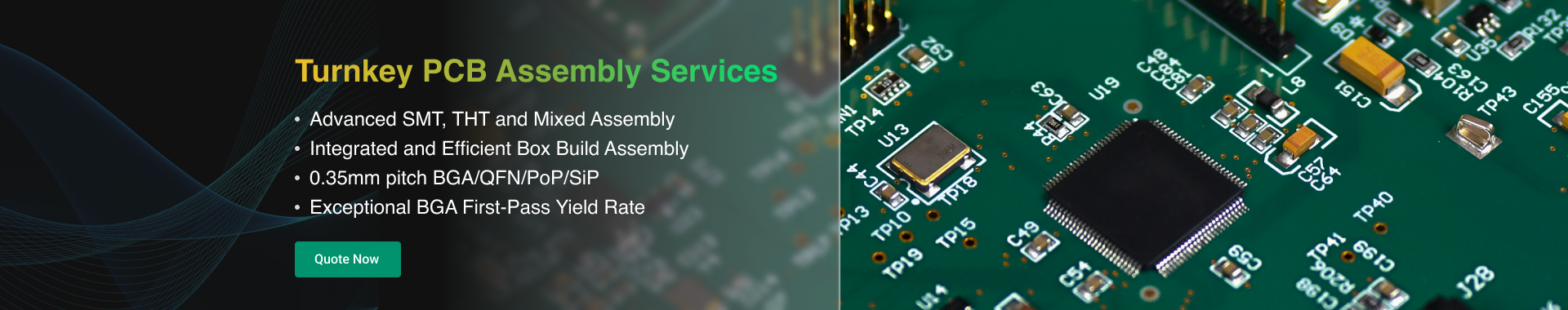

PCB AssemblyHOT

One-stop PCB assembly service.

read more

Fulfillment: Turnkey or consigned

Quantity: 1-10,000+pcs.

Quality Grade: IPC3

Lead time: as short as 2 days

Other: AOI, X-ray, SPI, ICT

PCB Layout

Optimize your designs with our precision PCB layout services read more

Layers: Up to 64

Capability: Support 150,000+ PIN

Services: Validation and re-engineering

Lead time: 3-10 days

Type: Rigid, Flex, Rigid-Flex, HDI

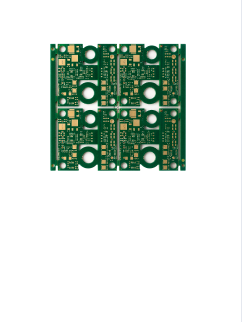

PCB Manufacturing

PCB prototype, standard and advanced PCB fabrication. read more

Layers: 1-32

From Prototype to Production

Quality Grade: Standard IPC3

Lead time: 2-15 days

Type: Flex, Rogers, Alu, etc.

BOX Build Assembly

Ready-to-ship electronic products,

tailored to your needs.

read more

Simple to multi-component systems

Tailored to your specifications

ISO9001, IATF16949, RoHS, UL

Cable/harness & electro-mechanical assembly, testing, packaging

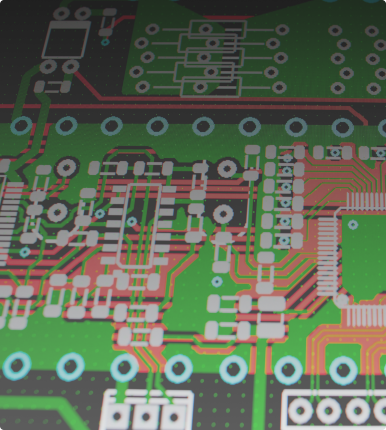

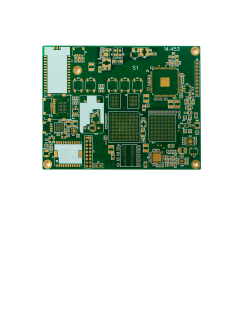

Reliable PCB Assembly

Focus on Small-Medium Volume PCB Assembly

High Quality

High Complexity

High Performance

Highlights

01005, 0201, CSP, WLP, Flip-Chip

0.35mm pitch BGA, QFN, PoP, SiP

Exceptional BGA First Pass Yield Rate

99% Satisfaction Across Batches

Assembly Types

SMT AssemblyTHT Assembly

Mixed Assembly

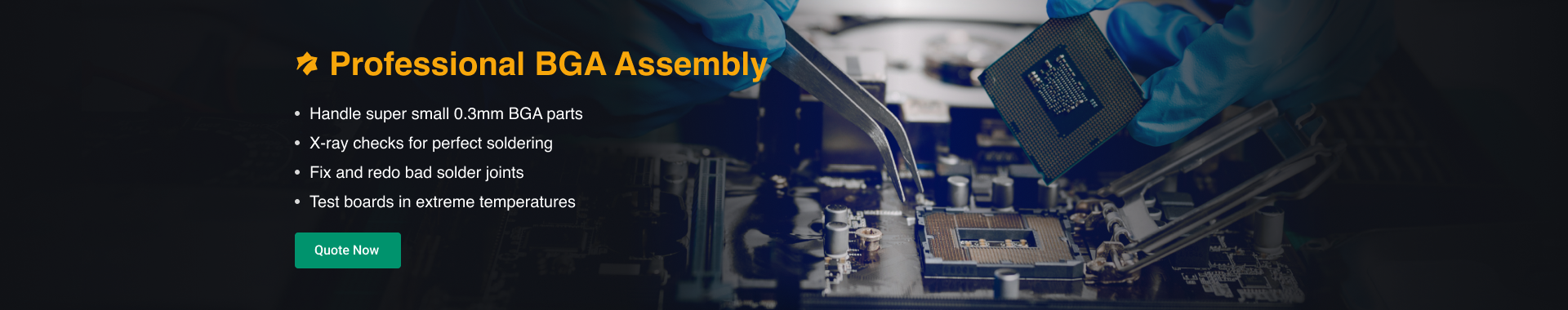

BGA & QFN Assembly

Kit Assembly

Fitch Component lnsertion

Component Types

SMT 01005 or largerCable & wire

BGA 0.35mm pitch, POP (Package on Package)

WLCSP 0.35mm pitch

Chip: min 01005

IC/Pedestal: min pitch 0.3

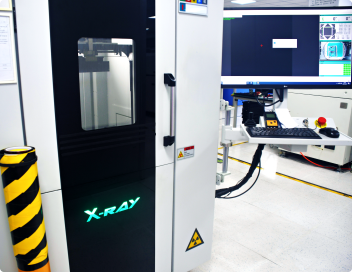

Comprehensive Testing

3D AOI

X-ray

FAI

SPI

50X Microscope

Innovative PCB Layout

PCBCart offers expert PCB layout services, providing complete electronic product solutions to a global clientele. We specialize in high-speed signal integrity analysis, schematic creation, precision PCB layout, and library development.

Capabilities

Up to 64 layers

Support 150,000+ PIN

High-precision 0.3mm BGA pitch

Max. 120+ connections

Min. 3mil line spacing

From Layout to Assembly

Layout seamlessly to assembly

Verified for assembly compatibility

Rapid layout-to-assembly flow

Skilled in processes management

Advantages

Detailed guidelines for accurate layout and routing

Robust systems for high-standard, error-free designs

Strict processes catch and address potential issues

Expert team reviews for optimal performance

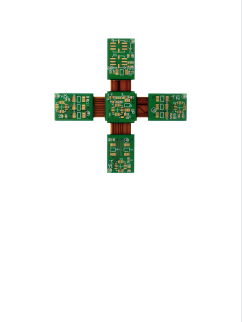

Advanced PCB Fabrication

Material and Layers

Alu: 4-24 layersRigid-Flex: 32 layers

Flexible: 1-8 layersHDI: 4-24 layers

Thick Copper: 2-24 layers

Additional Services

Free Valor DFM Check

Free tips on reducing production cost

Free Panelization Service

Custom Layer Stackup

Expedited Production Service

One-year Quality Warranty

Manufacturing solutions

Flex-Rigid PCB

Layers: 6 Medical

Flex-Rigid PCB

Layers: 6

Application: Medical

Board thickness: 1.0mm

Min. annular ring: 3.5mil

Min. via diameter: 0.2mm

Board size: 2.32*2.28inch

Min. trace/space: 10/5.2mil

Surface finish: ENIG (RoHS)

Heavy copper PCB

Layers: 12 Industrial control

Heavy copper PCB

Layers: 12 Copper weight: 5.5oz

Board thickness: 3.0mm

Min. annular ring: 6.625mil

Min. via diameter: 0.3mm

Board size: 5.19*4.86inch

Surface finish: ENIG (RoHS)

Min. trace/space: 10/9.75mil

Application: Industrial control

24-layer HDI PCB

Layers: 24 Communication

24-Layer HDI PCB

Layers: 24

Board thickness: 2.8mm

Min. annular ring: 4.53mil

Min. via diameter: 0.1mm

Board size: 3.54*2.75inch

Min. trace/space: 5.2/2.8mil

Surface finish: ENIG (RoHS)

Application: Communication

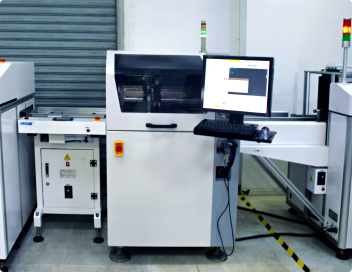

PCB Assembly Facilities Showcase

Advanced Equipment and Testing

Jet Printer and Dispenser (MYCRONIC)

3D AOI

High-Speed 3D Solder Paste Inspection System

High-Precision Solder Paste Printer

JTR-1200D-N Reflow Oven

KED600 Batch Cleaner

SE-450-HL Wave Soldering System

Panasonic NPM-W2 Chip Mounter

X-RAY

ZSWHPS-11-2 Selective Wave Soldering Machine

Jet Printer and Dispenser (MYCRONIC)

3D AOI

High-Speed 3D Solder Paste Inspection System

High-Precision Solder Paste Printer

JTR-1200D-N Reflow Oven

KED600 Batch Cleaner

SE-450-HL Wave Soldering System

Panasonic NPM-W2 Chip Mounter

X-RAY

ZSWHPS-11-2 Selective Wave Soldering Machine

Automated Production Line: Features the latest automatic three-proof paint spray and dispensing machines to meet diverse processing needs.

Comprehensive Testing Process: All quick sample products undergo 100% automatic optical inspection (AOI), visual checks, and X-ray testing before shipment.

Why Choose us

With 20 years of dedication and innovation, PCBCart stands as a top PCB manufacturing supplier, offering exceptional PCB Assembly and Layout services tailored to meet your specific needs with high quality and precision.

Singapore

Singapore

Parkview Square, Singapore

Parkview Square, Singapore

Thailand Factory

Thailand Factory

Samut Prakan Province, Thailand

Samut Prakan Province, Thailand

USA

USA

Katy Houston

Katy Houston

China Factory

China Factory

Hangzhou, China

Hangzhou, China

What is 4 Layer PCB?

Unlock the potential of 4-layer PCBs: the perfect blend of performance, innovation, and affordability, driving the future of smart electronics and beyond.

view detailsCommon PCB Issues and Repairs

Explore the crucial role of PCBs in electronics, where expert repairs address issues like trace damage and component failure to ensure seamless device performance.

view detailsPCB Board vs. Motherboard

Delve into the vibrant world of electronics, uncovering the distinct functions and fascinating differences between versatile PCBs and sophisticated motherboards.

view details