Printed circuit boards (PCBs) are the central structure in nearly all electronic appliances, ensuring efficient working and integration of components of the device. As our universe turns more and more into an electronic world, learning and fixing PCB issues becomes ever more important. In this guide, the most common PCB issues are addressed and light is shed on effective repair methods.

Understanding the Role of PCBs

A PCB is the structural backbone of electronic gadgets, offering mechanical support and electrical linkages in the form of conducting paths composed of materials such as copper and silver. PCBs play a vital role in deskside computers, wearables, industrial equipment, and so on. Without them, operations of devices would come to a standstill.

Given their importance, PCBs must be properly planned and maintained. Despite all the technological advancements, PCBs remain not free from faults that cause device malfunctioning. These range from physical and component faults to more insidious ones like trace and power failure. Solutions for these issues are necessary for rapid intervention and repair.

Common PCB Issues and Repair Strategies

Physical Malfunction

Physical destruction is the most obvious form of PCB failure. It most often results from mechanical stress in the form of drops, bumps, or handling mishaps. These actions have the potential to make substrates crack, connections get severed, and pads become raised.

Repair: Physical damage repair is typically a multi-step procedure starting with a complete visual and structural inspection to identify areas of damage. It may include reconnection of severed traces by precision soldering and replacement of shattered pads or components. Given the delicacy and precision involved, this should be accomplished by trained technicians with precision equipment to provide successful restoration and optimal performance.

Component Failure

Component malfunction is another common issue that can disrupt an electrical circuit of a PCB. Common culprits include capacitors, resistors, diodes, and integrated circuits. It might fail due to aging, thermal stresses, electrical overloads, or voltage surges.

Repair: Fault diagnosis of components begins with functional testing and visual inspection for signs of damage like burn spots, bulging, or discoloration. Advanced tools like multimeters and oscilloscopes aid in isolating the bad components. Discovered bad components are then carefully desoldered and replaced. Being compatible with existing circuitry is vital in order to avoid repeated failure, and this should be done by experts to shield the performance and stability of the PCB.

Trace Damage

Traces are the copper paths on a PCB that provide electricity between devices. They can be physically broken by wear, corroded by exposure to the environment, or electrically overheated. Intercepts of traces can cause complete or partial failure of circuits.

Repair: Repairing defective traces requires close detail work, sometimes involving cleaning the defective portion prior to filling in the area with conductive ink or wire bridges to ensure continuity of the circuit. Fresh copper traces are at times soldered over the defective areas. Repair by a professional ensures the continuity of the electric path to prevent shorting or degradation.

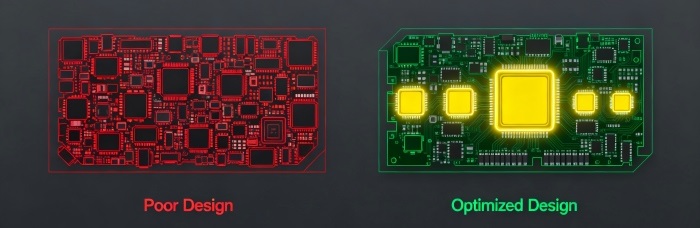

Poor Design

Design issues can lead to ongoing issues with a PCB, such as ineffective thermal management, insufficient spacing between components, or electrical contamination due to poorly designed traces. This can manifest in the form of inefficiencies in function, excessive heat generation, or ongoing component failure.

Repair: Correcting design defects usually involves reevaluating and redesigning the PCB layout. This may include trace rerouting for better flow, thermal reliefs, or choosing substitute components to improve performance. Having a professional PCB design service can assist in resolving such issues to make the board conform to the specified design requirements and perform suitably.

Power Failure

Power failure may be due to malfunctioning power supply circuits, voltage overloading, or PCB shorts. This will cause inefficient power distribution, and it can cause systems or components to shut down or fail to run.

Repair: Diagnosing power failure involves the use of detection equipment like voltage testers and logic analyzers to detect differences in power flow. Repair typically involves reseating loose components, replacing fuses or power devices, and reinforcing the power supply network. Repair in this manner should conform to electrical standards and be carried out by qualified technicians to prevent future issues and ensure safe operation.

Plating Gaps

Plated thru-holes allow interconnection among different wiring layers of the PCB. Plating gaps are the outcome of process defects during wiring layer electroplating or drilling, leading to the failure of electrical connections.

Repair: Gap fixing in plating often involves re-drilling the thru-holes and recoating with a new layer of copper plating. Precision in the process of electroplating is crucial to obtain complete functionality. Strict quality checking at every stage in the production process is necessary to prevent such defects. Should repair be necessary, skilled hands need to align and coat with caution to prevent failures from recurring.

Why Choose PCBCart?

We at PCBCart provide end-to-end solutions that cater to the specific issues of PCB problems. Our exhaustive list of services includes:

Review of schematic and circuit design

Post-manufacturing evaluation and testing

Sophisticated diagnostics and intricate repairs and modifications

BGA soldering and reballing services

With commitment to precision and reliability, PCBCart warrants all repair services performed with industry-leading practices and newest technology. Our professional expertise ensures the lifespan and performance of your PCBs, ensuring your device maintains its ultimate performance.

Fixing PCB issues with success requires significant electronics knowledge and proper repair execution. We at PCBCart balance technical know-how with advanced tools to diagnose and repair PCB defects, assured to keep gadgets operational. Trust our services as your PCB partner, where we help you minimize downtime while experiencing operational supremacy. Get in touch with PCBCart now for unparalleled PCB design, repair, and optimization experience.

Request for Advanced PCB Assembly & Manufacturing Quote

Helpful resources:

• Emergency Procedures for Leading PCB Defects

• The Most Common Problems in PCB Design and Their Analysis

• PCB Quality Inspection

• Common Defects in PCB Assembly and How to Prevent Them

• How to Ensure the Quality of PCBs