PCBs are fundamental to the current electronics as the basic backbone that allows and connects the electronic parts. FR-4 is a material that is currently the most popular in PCB manufacturing because of its cost-effective and reliability feature in a balanced manner. This article gives a detailed discussion of FR-4 PCBs, their features, production, benefits, and the points that a designer should remember.

What is FR-4?

FR-4 is a composite material that has very wide applications in PCBs. It is composed of woven fiberglass cloth and it has an epoxy resin binder, which has got good mechanical and electrical characteristics. The abbreviation FR means flame retardant, meaning the capacity of the material to extinguish itself when it is exposed to fire, to adhere to the UL94-V0 standard. One of the classification in the NEMA standards that lets the FR-4 be distinguished among other flame-retardant laminates is the 4, and this is why FR-4 is a reliable option in the design of PCBs that are safe.

Reasons Why FR-4 for PCB Production

Some of the main properties of FR-4 to be used in PCBs include:

Good Electrical and Mechanical characteristics:

FR-4 is available with high dielectric strength, which makes it a good electrical insulator that is required in the system to ensure good performance. Fiberglass nature provides the material with high mechanical strength that is resistant to physical forces, e.g. bending and impact.

Thermal and Moisture Resistance:

Having low water absorption, FR-4 can be used in humid environments, which is an advantage to marine and outdoor electronic products. Its normal glass transition temperature (Tg) is 130 deg C to 140 deg C, but there is a high-Tg version, with a higher stability range at high temperatures.

Cost-Effectiveness and Versatility:

FR-4 offers an inexpensive alternative without sacrificing on the key performance factors, with wide aperture of usage in consumer electronics, as well as in industrial machinery.

FR-4 PCB Manufacturing Process

The production of FR-4 PCBs is a series of steps followed with high discipline so as to ensure quality and functionality:

Material Preparation:

It begins with the production of FR-4 substrate. Prepreg layers are formed by impregnation with epoxy resin followed by fiberglass sheets, which in turn form the base on which copper layers are laminated.

Etching and Laminating:

In the case of multilayer boards, a step of laminating thin copper foil on the FR-4 substrate followed by a photoresist is applied. Resist is exposed to UV light by a mask, and through selective etching, undesirable copper is removed. The layers of etchings are built and compressed between prepreg and pressed under heat and pressure to glue the layers into a unified board.

Drilling and Plating:

Via and component lead holes are drilled in precision CNC machines. Copper is plated on these holes so that they are electrically connected well with the various layers on the board.

Surface Finishing:

Once the drilling process has been completed a protective solder mask is then applied over the board to protect the copper. A silkscreen is placed to label the components, usually with white ink, and finally the surface is finished by either HASL or ENIG to enhance solderability and prevent oxidation.

Testing and Quality Assurance:

A continuity and shorts test of continuity and shorts is done on each board. Using the routing or V-scoring method, the panels are then sliced into separate boards and the final product should be up to design standards.

Considerations in FR-4 PCB Design

FR-4 design should be considered observing several major aspects to ensure that the performance is optimized:

Selecting the Appropriate Thickness:

The FR-4 board is flexible, has impedance properties, and mechanical stress capacity, which depend on the FR-4 board thickness. In compact designs thinner boards are frequently used although can be difficult to assemble because they can bend more.

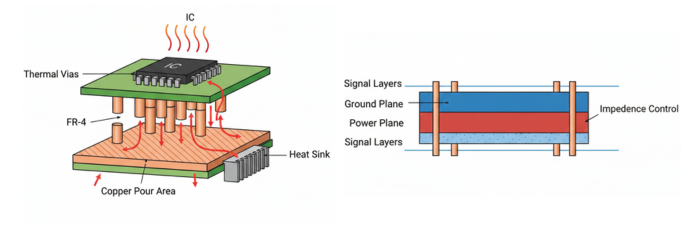

Optimizing Layer Stackup:

Layers stackup is a strategy that is vital in preserving signal integrity and managing electromagnetic interference (EMI). Signal, power, ground plane balancing can reduce the amount of crosstalk and maintain a steady impedance allowing high-speed circuits to operate.

Thermal Management:

Correct thermal management means should be applied to make sure that the board is capable of dissipating heat. This may be done by thermal vias, copper pours, and proper placement of components which will prevent degradation of performance owing to over heating.

Restrictions and Appropriate Alternatives:

FR-4 is not a perfect solution in all applications, though it can do it. It is not stable in high frequencies and high temperatures, and is therefore not as well suited to aerospace or RF applications, where the high thermal and dielectric stability are required. Such alternatives as high-performance laminates or PTFE substrates have to be considered in these cases.

The FR-4 materials play a very important role in the PCB industry as they offer an outstanding balance on cost-effectiveness and performance reliability. Their distinct product features of superior mechanical strength, electrical insulation and thermal and moisture resistance renders them the most suitable option in a broad spectrum of applications, including consumer electronics, and industrial systems. Knowing and exploiting the natural characteristics of FR-4, designers are able to maximize performance and reliability in their electronic undertakings. FR-4 boards can be used to provide successful and innovative electronic solutions at reduced costs regardless of the complexity of the designs or the complexity of simple configurations.

PCBCart is the leading partner in all your FR-4 PCB requirements, with the latest technology and an extensive experience in the production of PCB. Our stringent quality control, accuracy and customer satisfaction ensures that all the projects that we undertake are conducted in the best standards of reliability and performance. PCBCart offers customized solutions to your requirements, whether you are in need of simple single-level boards, or complex multilayer solutions. We would like to show you the quality of service and innovation that PCBCart provides. Get a quote today and allow us to make your electronic visions come true with the precision and quality.