PCB successfully added to your shopping cart

As the Chinese New Year holiday is approaching, please note that our office will be closed from February 14th to 23rd (10 days). During this period, responses to inquiries may be delayed, but you can still submit quotes and orders online as usual.

PCBCart Thailand Factory—Fully Prepared for Production! Learn More

Your First PCB Assembly Order

PCB Assembly Cost $500OFF

Coupon Code: FCPCBA

Applicable to turnkey PCB assembly services only. Other restrictions

may apply.

Product Portfolio &

PCB Assembly Services

IPC610-D Standards

ISO9001 Quality products

Over 99.8% Satisfaction rate

Under 0.1% Complaint Rate

PCB Manufacturing and Assembly

Services All in One Place

25,000+

different part numbers

delivered annually

100,000+

served customers in

120+ countries

Box Build Assembly

Rigid Flex PCB Assembly

.png)

High Frequency PCB Assembly

BGA Assembly Services

.png)

.png)

.png)

.png)

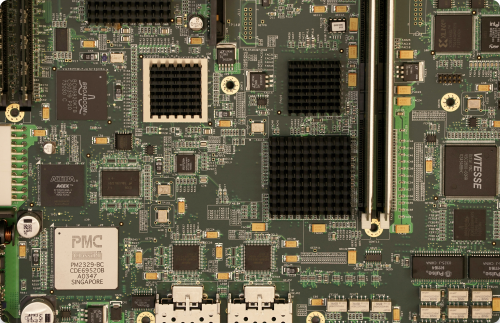

Just like the PCB business, our PCBA services at PCBCart are tailored

for prototyping, low-volume, and high-volume production, making us your

true one-stop solution for PCB fabrication and assembly. This integrated

approach streamlines your R&D, shortens lead times, and ensures

consistent quality. Backed by a professional engineering team, we

support you from design to delivery with services like free DFM/DFA

checks, BOM optimization, and functional testing. Fulfilling global

orders daily, PCBCart has built a reputation for high efficiency,

certified quality, and cost-effective solutions. Our ISO 9001 and IPC

Class 2/3-compliant factory is equipped with advanced systems and

inspection tools—such as AOI, X-ray, and functional test systems—to

guarantee reliable results from prototypes to full-scale production.

PCBCart Assembly Capabilities: SMT, THT, Mixed Technology, BGA, POP,

Rigid & Flex PCBs, Box Build, Full Turnkey, Partial Turnkey, Kitted

Assembly, Cable & Wire Assembly. Compliant with ISO 9001 and IPC 610

Class 2 & 3 standards.

Order Process

Fill in the quantity to get a quote for PCB assembly online.

Please upload your BOM file and PCB Gerber file so that we can quote you

faster and more accurately.

We will confirm the details (testing or programming) with you before

production. If you have any questions or need more information, please

feel free to contact your dedicated customer service.

Top Question

Via in Pad

Multilayer PCB

PCB Panels

PCB Materials

Layer Stackup

Full Feature PCB Manufacturing

Our PCB Assembly Solutions

PCBA

PCBCart offers turn-key PCB assembly services for prototype to

high-volume production, handling everything from component sourcing

and PCB fabrication to assembly, testing (including AOI/X-ray), and

final shipment, with capabilities including SMT, THT, mixed assembly,

BGA, POP, and RoHS-compliant processes.

PCB Fabrication

PCBCart offers a comprehensive solution that covers both PCB

manufacturing and prototype assembly, with a strong emphasis on

low-volume production and circuit board prototyping. We excel at

delivering high-quality, budget-friendly printed circuit boards,

including sophisticated multilayer designs reaching up to 14

layers.From impedance-controlled PCBs to boards featuring blind or

buried vias and intricate multilayer structures

PCBA Process

.png)

Before assembly begins, all incoming materials,

including fabricated PCBs and electronic components,

undergo rigorous quality control checks.

including fabricated PCBs and electronic components,

undergo rigorous quality control checks.

· Accurate resistance and capacitance values

· Consistency between component pads and the board

· Precise incoming quantity verification

· Detection of any abnormal components

· Consistency between component pads and the board

· Precise incoming quantity verification

· Detection of any abnormal components

.png)

A crucial step in the surface mount PCBA process flow, solder paste

printing involves applying solder paste to a printed circuit board

(PCB). The most common method utilizes a stencil printer to

accurately deposit the correct amount and thickness of solder onto

the solder pads.

.png)

Solder Paste Inspection (SPI) aims to identify defective solder

paste printing early in the Printed Circuit Board (PCB) assembly

process. SPI directly assesses the quality of solder paste on the

PCB, helping to significantly reduce defect rates and save

considerable cost and time.

.png)

Component placement is an electronic manufacturing PCBA process that

precisely mounts surface-mounted devices (SMDs) onto designated

locations on a printed circuit board (PCB). This step is essential

for establishing electrical interconnections between the components

and the PCB.

Manufacturers utilize Pre-Reflow Automated Optical Inspection (AOI)

to rapidly identify and address any defects before the PCBA

production moves to the next phase. This strategic inspection point

is vital for ensuring a reliable and efficient assembly process.

.png)

The reflow soldering process temporarily attaches electronic

components using solder paste. Through a controlled high-temperature

profile, the solder paste melts, allowing the surface-mounted

components to be firmly adhered to the PCB board.

.png)

Post-Reflow AOI can detect mis-soldering, reverse soldering, empty

soldering, empty soldering, lack of penetration, short circuit,

offset, tombstone, etc. after reflow soldering. It can also detect

defects such as excessive welding, insufficient welding, and

continuous welding in the appearance of PCBA solder joints.

.png)

PCBA through-hole component soldering is a vital step. Manual

soldering offers flexibility and precision for small batches and

prototyping, though with lower productivity. Wave soldering, on the

other hand, is ideal for mass production due to its high efficiency

and consistency, but it has limitations in component selection,

requires preheating, and can be more costly.

.png)

The first sample test involves cross-referencing the completed PCBA

with Gerber, BOM (Bill of Materials), and coordinate files. A

first-sample tester re-verifies the resistance and capacitance

values to confirm the accuracy of all parameter values.

.png)

X-ray inspection is commonly performed on Quad Flat No-Lead (QFN)

and Ball Grid Array (BGA) components during printed circuit board

assembly. This process checks the solder joints of otherwise

invisible components, ensuring the reliability of each solder ball

in a BGA.

.png)

The ultimate stage of the PCB assembly process is the final

inspection and functional test, which verifies that the PCB operates

as intended. Additionally, specific applications may have further

requirements. For example, automotive PCBs might undergo drop tests,

while medical PCBs may require halogen testing.

PCB Assembly Facilities Showcase

Advanced Equipment and Testing

Main Products

Jet Printer and Dispenser (MYCRONIC)

Main Products

3D AOI

Main Products

High-Speed 3D Solder Paste Inspection System

Main Products

High-Precision Solder Paste Printer

Main Products

JTR-1200D-N Reflow Oven

Main Products

KED600 Batch Cleaner

Main Products

SE-450-HL Wave Soldering System

Main Products

Panasonic NPM-W2 Chip Mounter

Main Products

X-RAY

Main Products

.png)

.png)

.png)

.png)

.png)