DESIGNED TO PERFORM

YOUR #1 SOURCE FOR

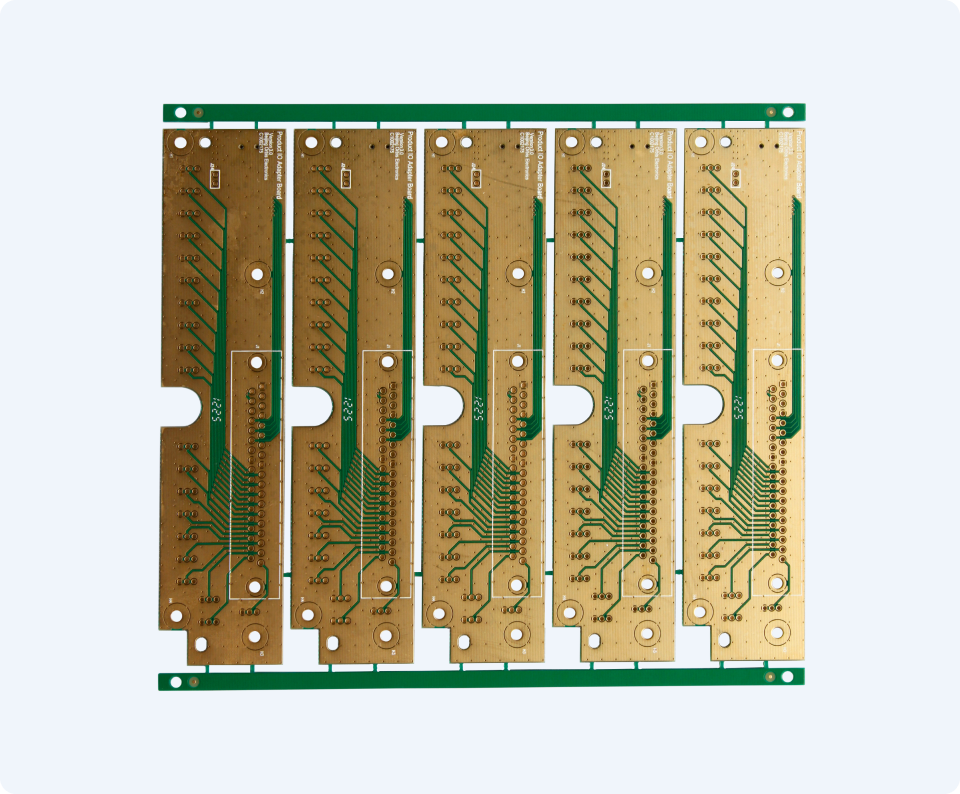

PRINTED CIRCUIT BOARDS

As the Chinese New Year holiday is approaching, please note that our office will be closed from February 14th to 23rd (10 days). During this period, responses to inquiries may be delayed, but you can still submit quotes and orders online as usual.

English

English

English

English

English

English

Español

Español

Deutsch

Deutsch

Français

Français

Italiano

Italiano

日本語

日本語

ภาษาไทย

ภาษาไทย

Malay

Malay

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

[email protected] [email protected]

[email protected] [email protected]

Thanks for your support! We'll go over your feedback in detail to optimize our service. Once your suggestion is picked up as the most valuable, we'll instantly contact you in email with a $100 coupon contained.