For a baker to make a cake, they need to buy the necessary ingredients, such as flour, butter and sugar. They also need access to the required tools, which include bowls, mixers, pans, an oven and other items. When this baker goes to the store to get the ingredients they need and any tools they're missing, they will likely take a list with them that tells them what to buy and how much of each item to buy. They might even note on their list where to buy each ingredient and other details, especially if they're sending someone else to get their ingredients.

Imagine, though, that instead of the baker making a list, it came from the customer who ordered the cake. Even worse, the baker has hardly had an opportunity to have face-to-face communication with the customer. The only way the customer told them what they wanted was through that detailed shopping list. The list also includes information about how to use each ingredient, enabling it to double as a recipe. This list is in many ways like a bill of materials, or BOM. Except with a BOM, instead of baking a cake, you're making a piece of hardware such as a printed circuit board.

What Is a BOM?

So what exactly is a bill of materials? A BOM is a comprehensive list of raw materials, assemblies and sub-assemblies, components and other crucial items for product manufacturing. Manufacturers must depend on the information included in their BOM to build a product, so it has to be highly accurate and sufficiently detailed. Customers use BOMs to explain to a printed circuit board, or PCB, assembler what exactly they need when they order circuit boards. The assembler uses it to build the board to the customer's specifications.

BOMs play a crucial role in the PCB assembly services we provide at PCBCart, as they do with other PCB manufacturers and assemblers.

What You Need to Know Before Creating a Bill of Materials

Creating a detailed BOM can take time, so it's tempting to skip this step. Developing one of these records, however, can make your PCB production process more efficient and can prevent costly mistakes, especially when it comes to more complex designs.

Before creating your BOM, you should have the answers to the following questions.

1. What are you building? Before you move on the BOM step, you should have at least begun the design phase of your project. If you don't, you won't know how to prepare your BOM. You might start compiling information about the parts you need as you design, but you can't start creating a BOM in earnest until you have your design ready. You should have made sure your plan worked as expected and produced a Gerber file, which explains the design information for a PCB to the manufacturer. This step will help you determine what parts to include in your BOM.

2. How will you manage your BOM? As you create your BOM, it'll likely go through multiple iterations, numerous people may handle it. Before you get started, you should establish a system for managing it and ensuring the latest version is in use. Track changes and create identifiers for different versions. Allow as few people as possible to edit the document, and decide ahead of time who will be responsible for what tasks to avoid confusion.

3. Who will use it? Because of the range of information this document includes, it's likely multiple departments, including design, engineering, purchasing and manufacturing, will use it during the PCB production process. Having an idea of who will need your BOM will help you include the correct information.

4. What information will you include? You don't need to know the specifics at this point, but you should know what categories you want to include in your document. Every BOM should consist of some basics, such as part name and quantity, but other items are optional. You need to decide if you'll include consumables — for example, glue and bolts. Do you have a preference for suppliers to buy parts from? Keep in mind, though, the best practice is to make your BOM as detailed and complete as possible.

5. How will you organize it? It can be helpful to decide on basic organization strategies before you begin. Consider how many levels and sub-assemblies — items you will assemble separately and then attach to the main assembly — your file will have, how you'll group items and any special designations you plan to have. If you create your BOM list format ahead of time, you'll be able to plug data in more efficiently once you start writing your BOM.

6. What program will you use to create it? Before you can make your bill of materials, you have to know what software you will use to create it. A BOM is essentially a spreadsheet, and many companies use Excel. As your business grows and your projects get more complicated, you may find you need a more advanced program expressly designed for BOMs, of which there are many.

How to Write a Bill of Materials

Once you have all that information sorted out, you can begin writing your BOM list. The process is relatively straightforward, but finding the information can be challenging. Here's how to prepare your BOM.

1. Create the document: Open the program you plan to use and create a new spreadsheet document. Name the file and put the name of the project and any other important identifying information at the top.

2. Organize the document: Establish user permissions, set up change tracking and create any levels you need. You might need to add more of this organizational information and make changes to it as you go.

3. Fill in the columns: Populate the names of the categories at the top of the columns. These titles will include things such as item name, quantity, part number and more. We'll discuss in more detail what you should include in the next section.

4. Fill in the rows: Populate the rows with information, according to the category of the column. Each component of your board will have a separate row. Ensuring that information is accurate and up to date is crucial to the success of your project.

5. Update as needed: Update the information in your BOM as necessary. As you create your file, remember to save it often and keep a record of changes. As you find out more about your project and circumstances, you'll likely find you need to be flexible as you go through the PCB production process.

What Should a BOM Include?

The information included in a BOM for PCB assembly may differ from project to project, but below are some of the categories of information that are commonly in them. Include as much of the following information as you can that's relevant to your assembly.

• Part number: To identify the exact parts you need for your PCB, list the manufacturer's part number on your BOM. This is how the assembler will ensure they use the right component. Every part number is unique, so there's no chance of confusion. Part numbers are also an international language, which is crucial in today's global economy.

• Manufacturer name: You should also list the name of the component's manufacturer to help those using the BOM to find the right part. It's important to take time to verify each piece is available from the manufacturer before listing it and to ensure it is suitable for your project regarding specifications, cost and delivery time. Checking this information early on will help avoid the extra time and costs of finding a replacement part later in the production process.

• Description: It can also be useful to list details about each part in the BOM, such as dimensions, voltage, color and other specifications. These details will help ensure the right part gets ordered and avoid confusion because of similar elements. Also, make sure you list the correct units of measure — whether that's centimeters, ounces, ohms or something else — with each description. For items that have multiple possible units, keep your choice consistent throughout the document.

• Quantity: The number of each part you need is another critical piece of information to include. Keep this information up to date, so you can take advantage of discounts for purchasing items in bulk.

• Procurement type: Listing the procurement type on your BOM spreadsheet can also help ensure you obtain the right part. This designation describes how a component is bought or made. For instance, is it purchased off-the-shelf or is it custom-made?

• Flexibility indicator: At times, it might not matter as much to you what manufacturer a part comes from. You might be willing to substitute a different manufacturer if the price is better. Sometimes, something might unexpectedly become available, meaning you need to be flexible if possible. Indicating your amount of flexibility in your BOM can help make the production process smoother. It's helpful to categorize items by how flexible you can be with them. Some parts you might mark as critical, meaning your assembler must follow your specifications exactly. Other parts might be important to your design, but able to be swapped for equivalent parts from a different brand. Generic parts could be labeled as non-critical, giving the assembler the freedom to switch the manufacturer and part number. They should still follow your other specifications, though. At PCBCart, we won't make a change or substitution with consulting our customer first.

• Alternate parts: If you have some flexibility regarding a part, you might include some potential alternate parts in case the component you initially requested is unavailable or another change arises. Doing so can reduce the amount of time lost in these situations. You might want to note whether these alternates are the only acceptable substitutions, or just examples.

• BOM level: BOMs often contain multiple levels, which each represent either the main assembly or a sub-assembly. Each BOM has its own structure that is divided and marked based on BOM levels to help users navigate the document and understand the assembly.

• Supporting files: As you design your board, you'll create files such as CAD files, data sheets, diagrams and instructions that don't fit into the BOM spreadsheet. In these instances, you'll want to attach these supporting documents and associate them with the appropriate BOM level and components.

• Reference designator: Create a unique reference designator for each part of your PCB assembly that indicates where the piece goes on your board. Making this designator the same as the label you use in your PCB design documents will help you cross-reference your BOM and PCB layout easily. These identifiers often consist of a letter and a number. Resistors, for example, might be named R1, R2, R3 and so on.

• Package type: You should also include in your materials document a description of the package or case type each surface mount component should be in. These packages are designed to streamline production, and choosing the right package type can make the process more efficient and cost-effective. Examples of package types include small outline packages, single in-line packages and ceramic column grid array packages.

• Placement method: For PCBs, you'll also need to list the placement method or surface mount technology your project will use, which describes how each component will attach to the board. These methods include through-hole and surface mount technology (SMT).

• Board layer: This category indicates what layer of the board the component will be placed on. This might be the top or bottom of the board, or in multi-layer boards, somewhere in the middle.

• Points/footprint: Notate the number of connection points each component has on the board. Also include the footprint of each part, which explains the arrangement of connectors, such as through-holes or pads in SMT, that attach them to the board both physically and connect them electrically. You should note the points and footprint for both individual components and each BOM level.

• Phase: You may want to include space in your sheet to mark where in their lifecycles parts are. Designations in this category include production, testing and design. This helps you keep track of your assembly's progress and create realistic project timelines.

• Comments and notes: Although this is not a critical category, it can drastically increase the efficiency of your project, especially when problems or unexpected changes arise. This is the section where you put any comments and notes that don't fit into any other category.

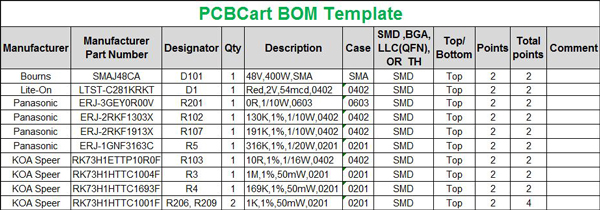

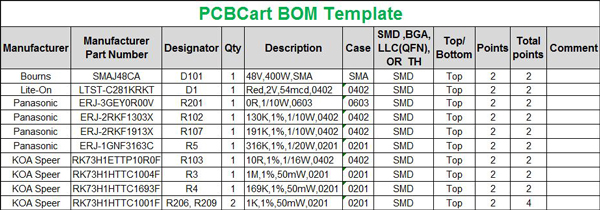

BOM Example

Here's an example of part of a BOM that includes some of the information mentioned above. You'll notice the sheet is clean, organized and clearly labeled, and that information is noted consistently throughout it. This is just an example BOM list, and yours will likely be longer and contain more information.

In the far left column of the bill of materials example above, you'll see the name of the manufacturer. Next to that is the manufacturer's part number, the quantity and a description of the item with units. After that is the case or package type. Next is the placement method. This BOM provides the option of selecting SMD, BGA, LLC (QFN) or TH. All the components in this list call for SMD placement. They will also go on the top of the board with two connection points. Because the last item has a quantity of two, it has four total connection points, while the other components have two total. In the final column is a space for additional comments.

BOM Creation Tips

• Tailor your BOM to your needs: Before you create your BOM, decide what you and your partner companies need from it and design it to meet those needs. Different companies do BOMs in different ways, and different projects require different organization, information and other features. Customize your BOM according to the unique demands of your project.

• Use a template: Each PCB manufacturer and assembler has BOM templates you can obtain from their sales departments or websites before you request a quotation. Using a template from the company with which you're working helps avoid problems with accessing and opening the BOM document and technical issues caused by incompatible file types.

• Include the right amount of details: Include as much helpful information as you can in your document. Remember, your BOM plays a crucial role in explaining your PCB assembly to people who have to build it entirely from scratch. These people may have never spoken to you in person, and they might not even speak the same language. For this reason, you need to make your BOM as clear, detailed and precise as possible. Some types of information aren't helpful and will only create confusion, but use your best judgment on this. In general, the more details, the better.

• Double-check all information: Before uploading or sending your BOM to a manufacturer, check it meticulously to make sure all the included information is correct and you can navigate the document the way you intended. Even relatively small mistakes can be costly when it comes to PCB assembly.

• Keep track of changes: Ensure you have a system in place to keep track of all changes to the document. You may want to keep a record of all previous versions in case you want to refer back to them. Just make sure each version is clearly labeled and that the most up-to-date one is always the one in use for the project.

• Limit editing capabilities: Although a lot of people might need access to your BOM, don't give them editing permission unless necessary. Instead, give them read-only access to the document. Restricting editing ability can prevent accidental and misinformed changes. Also, consider creating a unique identifier for everyone with editing capabilities, so you know to whom they should direct questions about the information in the BOM.

• Consider automation: Consider introducing aspects of automation to your BOM management. Doing so can help you identify discrepancies among records and allow for enhanced traceability. It can also make it easier to import and export information for various file formats. Automation features are more prevalent with dedicated BOM systems and may require the purchase of additional software.

PCB Assembly From PCBCart

At PCBCart, we focus on quality and offer a full range of PCB services, including procurement, fabrication and assembly. We make it easy to get your PCB project completed with our one-stop approach and a range of helpful tools. Browse our free online resources, or contact our knowledgeable support team for help at any stage of your project.

We also offer instant online quoting, ordering and reordering. If you already have everything ready for a PCB assembly quotation, click below button to submit your circuit specs, PCB files and BOM.

Request for Free PCB Assembly Quotation

Helpful Resources

• Pre-order File Checklist

• Design PCB to Better Take Advantage of PCBCart's Assembly Capabilities And Save Cost

• Step-by-step Instruction On Requesting PCB Assembly Price