Recent years have witnessed increasingly wide applications of flexible PCBs. Flex PCBs were primarily applied in military field at their early phase, specifically applied in aerospace and military products. The constant development of technology has gradually seen the expansion of flex PCB boards into civilian field. Up to now, flex printed circuit boards are widely applied in computer peripherals and home appliances such as ribbon lead of hardware drive, automotive electronics, cameras, digital video cameras, instruments, office automation devices, health care equipment etc. Recent years have seen their applications in Chip on Flex (COF) film working for Liquid Crystal Display (LCD) modules. With the gradual widening of application field of flexible PCBs, great changes have taken place to their structural form, product functions and performance. Therefore, higher performance requirement has been set on substrate material of flexible PCBs including high heat resistance, high dimensional stability, high flexibility, high frequency (low dielectric constant) and non-halogenation. As substrate material of flexible PCBs, flexible CCL (copper clad laminate) has to upgrade in terms of its performance so that comprehensive performance of flexible PCB will be finally improved. This article will cover basic aspects of flex CCL so that agreeable flexible substrate material can be picked up for optimal performance of your flexible PCBs.

Development History of Flexible CCL

Flexible CCL refers to single-layer or double-layer flexible copper clad laminate made of PI film or polyester film as substrate material that are insulating and thin copper foil conductor with flexibility on surface. Compared with rigid CCL, it features light weight, thinness and flexibility so flexible PCBs with flexible CCL as substrate material are expansively applied in numerous electronic products including cell phone, digital camera, automotive GPS, laptop etc.

The earliest flexible CCL could start from conductors made of wax paper substrate in 1898. In 1960, engineers first applied copper foil on thermoplastic film with pattern generated by etching so that circuit pattern will be finally generated on flexible circuit board. After more than 50 years' development, flexible CCL has received such increasingly wide applications that they play an indispensible role in consumer electronic products such as pad, cell phone etc.

When it comes to the development of flexible CCL in China, it started as early as 1980s. Then, flexible CCL began to take off at a high speed. Up to now, the overall manufacturing capacity has exceeded 108 m2, ranking among top countries around the world.

Classification of Flexible CCL

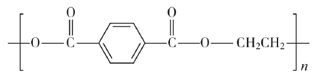

Based on different layers, flexible CCLs can be classified into single-side flex CCL, double-side flex CCL and multi-side flex CCLs; based on different trace density, flexible CCLs can be classified into ordinary flex CCL and high-density flex CCL; based on different substrate material types, flex CCLs can be classified into polyester type flexible CCL, PI type flexible CCL and polytetrafluoroethylene type flexible CCL; based on different product structures, flex CCLs can be classified into 3L-FCCL and 2L-FCCL that are demonstrated in the following image.

In accordance with the depiction of this image, 3L-FCCL is also called adhesive flex CCL while 2L-FCCL is also called non-adhesive flex CCL.

Structure of Flexible CCL

Flex CCL is mainly composed by conductor material and insulation basilar film. Adhesive is also contained in 3L-FCCL, as is depicted above.

Conductor material contributing to flex CCL includes copper foil, aluminum foil and copper-beryllium alloy and copper foil accounts for the majority. Copper foil can be further classified into electrolytic copper foil and rolled copper foil each type of which is ranked into different levels. Because electrolytic copper foil and rolled copper are manufactured in different methods, they differ a lot from each other in terms of mechanical property and flexibility and so does in copper roughing treatment.

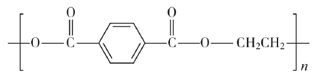

As a primary element of flex CCL, insulation basilar film is classified into polyester film, PI film, polyesteride film, fluorocarbon ethylene etc. among which polyester film and PI film account for the majority. Polyester film is actually polyethylene terephthalate film whose chemical structure is displayed as below.

It features excellent water resistance and dimensional stability after moisture absorption and performs well in terms of mechanical properties and electrical performance. Its disadvantages, however, is bad heat resistance and it tends to go through high shrinkage when heated. Moreover, it features a low melting point, which is not acceptable for high-temperature soldering.

PI film features excellent mechanical performance and electrical property. It performs well in heat resistance with long-term application temperature of 260°C and can withstand transient high temperature that is over 400°C with good fire resistance. Therefore, PI film is always applied for flex CCL now.

As a key component, adhesive directly determines performance and quality of 3L-FCCL products. Adhesive used for flex CCL includes polyester type, acrylic acid type, epoxy or modified epoxy, PI type and phenolic-pvb type etc. Nowadays, acrylic acid adhesive and epoxy adhesive are widely applied.

Development Trend of Flexible CCL

Flexible CCLs have witnessed a wide application field in the future. Simultaneously, much progress has been made on new types of flexible CCLs by researchers, such as high-Tg flex CCL, halogen-free and phosphor-free flex CCL, high-speed flex CCL and ultra-thin flex CCL.

• High-Tg Flex CCL. As far as 3L-FCCL is concerned, the key point of high-Tg flex CCL lies in heat resistance improvement of adhesive. Adhesive applied in 3L-FCCL is now primarily epoxy resin and acrylic acid. As a result, high-Tg flex CCL has to keep manufacturing cost as low as possible with dimensional stability, insulation and chemical resistance first ensured.

• Halogen-Free and Phosphor-Free Fire-Resistance Flex CCL. Due to EU regulations release and people's calling for environmental protection, halogen-free and phosphor-free have become the new development target of flex CCLs.

• High-Speed Flex CCL. Recent years have seen high frequency and high speed of signal transmission so that new need in terms of high frequency and high speed has been called for.

• Ultra-Thin Flex CCL. Light weight demand of electronic products has scattered around flex CCLs, which is the leading reason for ultra-thin flex CCLs.

Get an Instant and Reliable Quote on Flexible PCB from PCBCart

As a matter of fact, you don't need to order flex CCL whenever you've picked up a trust-worthy PCB manufacturer because it's their responsibility to provide flex PCBs with the best performance which depends on properties of flexible CCLs. What you need to do is just have a Quote on Flexible PCB on PCBCart.com and win an opportunity to flourish.

Request FREE Flex PCB Quote

Helpful Resources

• A Comprehensive Introduction of Copper Clad Laminate

• 5 "Whats" about FR-4 Copper Clad Laminates

• Comprehensive Introduction on PCB Material

• Flexible and Flex-Rigid Printed Circuit Board Applications

• Flex PCB Manufacturing Service from China

• PCBCart Also Offers Flex-rigid PCB Manufacturing Service