At PCBCart, we realize that PCBs are the basic building blocks powering all modern electronics, from commonplace consumer devices through to life-critical applications in aerospace and medicine. Our commitment to uncompromising quality and reliability for each PCB that leaves our factories starts with adherence to international industry standards, and none come more critical than those dictates laid down by IPC—Association Connecting Electronics Industries. As a valued PCB manufacturing partner, PCBCart integrates IPC standards into every stage of our quality control process, utilizing its framework to produce consistent, high-performance products that meet the varied needs of our customers.

What are IPC standards, and why are they important in quality control?

IPC standards are globally recognized guidelines developed by industry experts with the intent of standardizing PCB design, manufacturing, assembly, inspection, and testing. Far beyond optional best practices, these over-300 published standards give engineers, manufacturers, and suppliers a common language and align them with quality criteria throughout the supply chain. At PCBCart, IPC standards form the backbone of our quality control system in that they stipulate clear acceptability criteria, reduce variability, and minimize risks associated with defects, rework, and product failures.

Importantly, IPC standards are not legislated, yet their widespread acceptance has made them the standard of excellence for PCB quality. Compliance with these guidelines enables PCBCart to guarantee that our PCBs will be compatible with components from various suppliers, will meet the performance expectations of our customers, and will also adhere to particular regulations that may apply for specific industries, like medical or aerospace applications. Real-world results prove their value: companies following IPC standards have seen dramatic reductions in recall rates-for instance, an airbag unit recall reduced from 400,000 to just 990 cars thanks to its adherence to IPC-1782 traceability.

Core IPC standards that shape the quality control at PCBCart:

Key IPC standards undergird the quality control process at PCBCart for every step of PCB production, from bare board fabrication to final assembly. These include granular criteria for inspection and performance to ensure that no detail has been overlooked:

• IPC-A-600 : This standard is the foundation for bare PCB acceptability. It provides visual quality criteria for surface conditions, conductor patterns, hole quality, solder mask alignment, and edge conditions. PCBCart follows this standard in the inspection of raw PCBs prior to assembly, with strict limits on defects according to the product's class based on IPC standards.

• IPC-6012 : Rigid PCB performance should be specified, addressing material life, capability to withstand thermal stress, and electrical performance. The said document ensures our PCBs can withstand operational conditions-from extreme temperatures in aerospace to constant usages in consumer electronics.

• IPC-A-610 : This standardizes the acceptability of electronic assemblies in areas like soldering, component placement, and cleanliness. For the assembled PCBs (PCBAs), PCBCart follows its class-specific criteria to guarantee reliable connections and long-term functionality.

• IPC-2221 : Formalizes design guidelines on trace widths, spacing, layer stack-ups, and material selections. Included at the front end in the design phase, our engineering team uses these rules to improve manufacturability and head off quality issues before they arise.

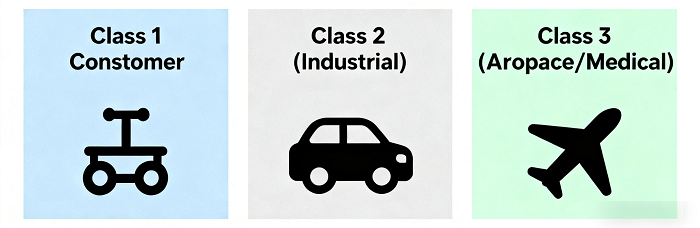

IPC Classifications: Tailoring Quality Control to Application Needs

IPC specifications divide PCBs into three classes by reliability and functional requirements within the application, enabling PCBCart to tailor our quality control processes for each project:

• Class 1 (General Electronic Products) : For low-cost, short-lifecycle products such as toys and other simple consumer gadgets. Quality control is mainly concerned with functionality, with lenient criteria for cosmetic defects that do not affect performance.

• Class 2 (Dedicated Service Electronics) : these include industrial controls, automotive electronics, laptops, and office equipment; in other words, those that require high dependability and constant performance. PCBCart provides detailed visual inspection, closer tolerances for conductor spacing and soldering, and upgraded documentation for Class 2 PCBs.

• Class 3 (High-Reliability Electronics) : This is when applications related to aerospace, defense, and critical medical machinery are included, failure of which may result in severe damage. Our quality control for Class 3 PCBs includes highly detailed inspections like 10x magnification and automated optical inspection, stringent requirements regarding plating thickness (minimum 25 microns for through-holes), 75% barrel fill for PTHs, and comprehensive documentation with complete traceability.

In conforming our quality control to the relevant IPC class, PCBCart has made sure that each PCB meets the exact reliability requirements of its intended usage-no more, no less-delivering the best value to our customers.

How PCBCart Applies IPC Standards for Strict Quality Control

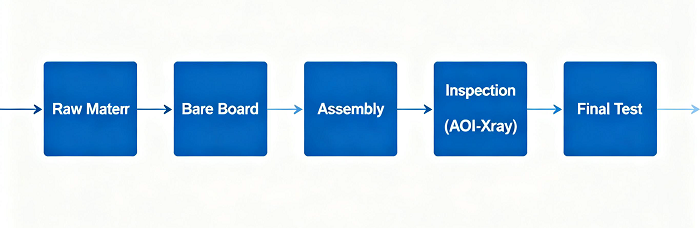

IPC compliance is not treated as an afterthought at PCBCart but rather as an intrinsic part of the manufacturing culture. We adopt a systematic approach in integrating IPC standards into every link of quality control:

• Team Training and Certification : Our engineers, inspectors, and production staff undergo the IPC certification training program, including IPC-A-600 and IPC-A-610 Certified IPC Specialist training, to deeply understand the requirements of standards.

• Material Quality Assurance : We acquire raw materials from trustworthy suppliers in line with IPC specifications and conduct incoming checks on them for copper thickness, dielectric properties, and thermal stability.

• Multi-Stage Inspection Processes : We combine manual visual inspections with automated tools (AOI, X-ray inspection) to check PCBs at key production stages—raw material intake, bare board fabrication, assembly, and final testing. For Class 3 PCBs, we add microsectioning to verify internal structures like plating quality.

• Defect Tracking and Continuous Improvement : Detailed records are kept of defects, and statistical process control is used to monitor the rate of defects, with targets of less than 1% for Class 2 and near zero for Class 3 production. These statistics lead to process optimizations to prevent recurrence of defects.

• Supplier Collaboration : We audit and collaborate with suppliers that meet the IPC standards for consistency down the whole supply chain, from components to manufacturing equipment.

Overcoming IPC Compliance Challenges

As much as the IPC standards detail what has to be adhered to, the challenge in compliance usually comes in the form of inconsistent inspection results, material variability, and higher production costs related to Class 3 production. PCBCart addresses these by:

• Standardizing inspection processes by using checklists and automation to reduce human error.

• Working exclusively with certified suppliers and conducting regular material audits to ensure consistency.

• Emphasis will be on defect prevention rather than rework, through DFM reviews using IPC-2221 to reduce waste and cost for high-reliability PCBs.

Conclusion: Commitment to Quality for PCBCart through IPC Standards

More than specifications, IPC norms are the bedrock of trust in the electronics industry. At PCBCart, our dedication to IPC compliance implies that every PCB that leaves our facility meets the highest standard of quality, reliability, and consistency. Whether you require a Class 1 consumer PCB or a Class 3 aerospace-grade assembly, your product is matched with quality control processes that find their root in IPC's rigorous framework.

By choosing PCBCart, you are partnering with a manufacturer committed to the role IPC standards play in quality control. We combine technical expertise, certified processes, and continuous improvement to deliver PCBs that perform as expected, reduce your risk of failures, and enhance the value of your end products.