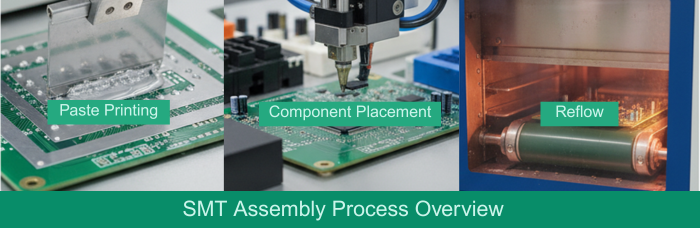

SMT constitutes the backbone of modern electronics, allowing for high component density and smaller form factors that characterize modern-day devices. However, the soldering process under SMT is intrinsically complex, dependent upon the exact interaction between design, material science, and thermal dynamics. This complexity opens the process to several kinds of defects that can severely compromise quality and long-term reliability in electronic assemblies.

High-yield zero-defect production means everything to them. It means being very meticulous and proactive in ensuring control over the entire chain from initial design to final inspection. The following article deals with the most important SMT defects, describes the root of their causes, and explains some robust and professional methods to ensure the best production results.

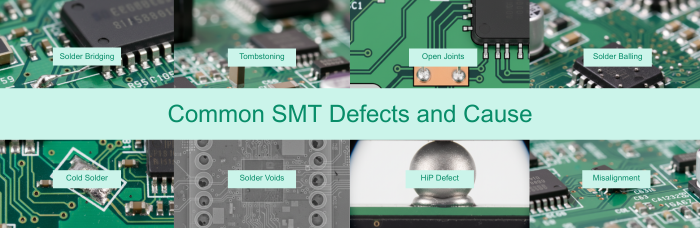

Core SMT Defects and Causes

The majority of problems in SMT arise from inconsistencies in the volume and placement of solder paste.

Solder Bridging (Shorts): This is an unintended electrical connection between adjacent conductors, mainly due to excessive solder paste deposition. Other causes include paste slumping or inadequate pad spacing in the PCB design.

Tombstoning (Manhattan Effect): This defect occurs when a small chip component stands vertically on one end because of an imbalance in the molten solder forces. This usually results from uneven heating of the two pads or unequal solder paste volume.

Insufficient Solder/Open Joints: This generally leads to a weakened connection or no connection at all. This is most often caused by lack of solder paste volume due to obstructed stencil apertures or poor stencil design. Poor component lead coplanarity is a contributing factor.

Solder Balling and Solder Beading: These are small, round solder particles that are usually created by moisture contamination in the solder paste, causing sputtering to occur during the initial heating phase, or by excessive paste volume leading to solder beads along the component edge.

Cold Solder Joints: This type of defect is characterized by a dull and granular appearance. It signals a failure to form a proper metallurgical bond because of inadequate heat during the reflow process or oxidation on the pads and component leads.

Voids in Solder Joints: These are the internal air pockets that weaken the joint and reduce thermal performance, usually caused by the entrapment of flux or volatiles that outgas during the reflow process.

HiP Defect: The solder ball of a BGA component detaches from the solder paste "pillow" of the pad. It is quite common for BGA components, due to warpage of the component or PCB, or oxidation on the component balls.

Component Misalignment: This defect occurs due to incorrect positioning of components on their respective pads. Most often, this is because of the pick-and-place machine inaccuracy or component movement during the process of reflow.

Strategies for Defect Avoidance and Process Control

The effective prevention necessitates strict control of DFM, material handling, and thermal profiling.

Solder Paste Printing Excellence (Printing Controls)

Optimize Stencil Design: Employ Solder Paste Inspection systems right after printing to check for correct paste volume and alignment.

Aperture Adjustments: Stencil apertures for fine-pitch components are reduced in size to avoid excessive deposition that causes bridging.

Control Environment: Store and handle solder paste strictly according to the manufacturer's specifications because one of the prime reasons for solder balling is moisture absorption.

Quality of Stencil: Stencil should possess an Area Ratio of at least 0.66 to ensure good paste release and avoid solder starvation.

PCB and Component Design (DFM Solutions)

Implement Thermal Relief: Apply thin spokes connecting pads to large copper planes so that the thermal mass is balanced and simultaneous melting occurs. This prevents tombstoning.

Symmetrical Pad Design: Component pads must be of similar size and shape to ensure a balance in the reflow process.

Solder Mask Dams: Use SMD (solder mask defined) pads for the fine-pitch components; make sure solder mask creates physical dams between pads to avoid bridging.

Verify Component Coplanarity: Check incoming components for bent leads or warpage; poor coplanarity directly leads to open joints.

Reflow Soldering Optimization (Thermal Controls)

Reflow Profile Tuning: The use of a gradual ramp rate in the preheat and soak zones allows flux to activate and volatiles to escape slowly to minimize both sputtering (solder balling) and thermal shock (tombstoning).

Achieve Proper TAL: Ensure the reflow profile allows enough TAL to promote good wetting and the formation of a strong metallurgical bond, thereby avoiding cold solder joints.

Nitrogen: For the most critical applications, the use of a nitrogen atmosphere in the reflow oven minimizes oxidation and greatly enhances wetting while reducing voids and HiP defects.

Inspection and Quality Assurance

AOI/X-ray: Utilize AOI after reflow for the detection of external defects, such as bridging and misalignment, and use X-ray inspection for non-viewable joints for the detection of voids and HiP defects within the BGAs.

Equipment Calibration: Perform regular calibration of pick-and-place equipment to ensure the perfect centering of components on their pads, addressing misalignment directly.

High-quality, reliable SMT assembly can be achieved by integrating robust DFM principles with accurate process control throughout-from verification of solder paste volume through SPI to reflow thermal profile optimization for balanced heating and optimal TAL. In so doing, manufacturers, by systematically addressing the root causes of the most common defects-bridging, tombstoning, and voiding-can effectively mitigate risk, ensure metallurgical integrity, and produce electronic products that perform to the highest standards throughout an exceptionally long life.

With PCBCart, quality is not just a target; it's a guarantee. Utilizing state-of-the-art equipment, such as 3D SPI and X-ray inspection, together with stringent process controls and expert DFM review, we proactively eliminate defects before they can occur. Whether you need a complex assembly that moves quickly from design into a reliable final product, count on PCBCart. Get an instant quote today and enjoy the confidence that comes with defect-minimized, high-yield PCB assembly.

Get an Instant Quote for Cost-Effective SMT Assembly

Helpful resources:

• Common Defects in PCB Assembly and How to Prevent Them

• How to Solve Solder Joint Problems in SMT Processing

• BGA Assembly Capability and Common Issues

• Advanced PCB Assembly Services