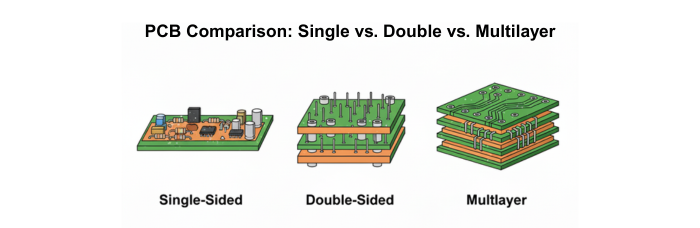

Printed circuit boards are the silent backbone in this world of electronics manufacturing, powering a wide range of devices from simple household appliances to complex industrial systems. These serve as both mechanical supports and electrical connectors for electronic components. The different configurations include single-sided, double-sided, and multilayer. Each type comes with its characteristics, cost implications, and applicability. This article examines in detail these three types and takes you through their features to help you decide which will best suit your project requirements.

The Basics of PCB Design and Structure

It cannot be overemphasized how vital the role of a PCB is in electronic hardware. A PCB connects electronic components together as functionally and as smooth as possible. The functionality, complexity, and cost of any device often depends on a single-sided, double-sided, and multilayer choice a PCB presents. Keeping these distinctions in mind can make quite a difference while an engineer designs electronic solutions efficiently.

Single-Sided PCBs

Single-sided PCBs are the most basic form of these boards. As the name would suggest, they consist of one layer of conductive material, copper normally, but attached to a base, usually made from fiberglass (FR4). One side of the board has copper traces etched into a precise pattern to direct electrical currents across the board. The other side contains all the components.

Advantages:

Cost-Effective Production: The simplicity in design and manufacturing translates to lower costs, making single-sided PCBs the most economical option, ideal for straightforward designs.

Ease of manufacture: Their structure is very simple; hence, they are easy to produce and give few problems when it comes to troubleshooting and maintenance.

Rapid Prototyping: Single-sided PCBs can be produced much faster due to their simple design; hence, these are highly useful in projects that require quick turnaround times.

Limitations:

Limited Complexity: Having only one layer limits the complexity of the circuit design to simple electronic functions.

Increased Size Required: The limitation of a single layer constrains miniaturization, adding to the size and weight of end-product devices.

Applications:

Single-sided PCBs have their strong points in cost-effectiveness and ease of assembly, therefore, are suitable for:

Consumer electronics such as calculators and home appliances.

Basic electronic components include power supplies.

Audio devices and accessories.

Printers and simple cameras.

Double-Sided PCBs

Double-sided PCBs provide more flexibility during the design of circuits due to their conductive layers on both sides of the substrate, hence making circuits with more complexity in electrical pathways. Vias, small holes drilled into the board, connect the circuits on the two sides and enable currents to travel between layers.

Advantages:

Increased Flexibility and Complexity: The ability to place components on both sides with their interconnected pathways greatly enhances circuit complexity without doubling the size of the board.

Improved Performance and Density: More elements can be accommodated in one area than on single-sided boards, enhancing the performance of electronic items and space utilization.

Cost-Effective for Complex Designs: While they are more expensive than single-sided PCBs, they offer cost-effectiveness in cases when multilayer configurations are not required for intermediate levels of complexity.

Limitations:

Higher Production Costs than Single-Sided PCBs: The dual-layer setup and via implementation add to manufacturing costs.

Increased Complexity in Design: Designs that can utilize both sides efficiently require skill and precision; hence, design difficulty increases.

Applications:

These PCBs are crucial in more complex electronics, such as:

LED lighting applications.

Automotive dashboards and controls.

Vending machines and ATMs.

Complex industrial and HVAC control systems.

Standard computing peripherals and networking devices.

Multilayer PCBs

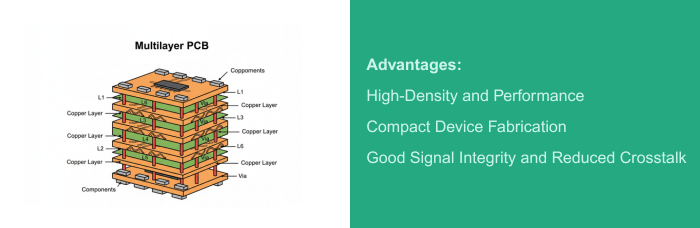

The multilayer PCB represents the highest complexity level for PCBs, having three or more copper layers. These layers are separated by insulation and then laminated together using high heat. This complex layering will support sophisticated electronic designs and a high density of pathways, allowing devices to be compact and powerful.

Advantages:

High-Density and Performance: This feature multiple layers that increase circuit density and complexity, well adapted for high-performance applications.

Compact Device Fabrication: This design allows compact and light electronic devices to be developed, a feature of high importance in many modern technologies.

Excellent Signal Integrity and Reduced Crosstalk: The multiple layers act as a buffer between signals, minimizing electrical interference and improving overall signal integrity.

Limitations:

High Production Costs: The complications in design and manufacturing greatly increase the cost compared to single and double-sided boards.

Complex Manufacturing Process: The process of fabrication is very intricate, requiring advanced technology with long lead times.

Challenging Repairs: Multilayer boards are more difficult to repair and diagnose because of their complex construction.

Applications:

Multilayer PCBs are fundamental in today's technology, including:

Smartphones and tablets.

Advanced medical devices, including heart monitors.

Aerospace and military electronics.

Complex computing and data center systems.

Scientific instruments and high technology consumer gadgets.

When selecting the appropriate PCB for your project, it is essential to assess your design requirements against your budget and the demands of your application. Single-sided PCBs are suitable for low-cost and simple electronic products, double-sided PCBs for intermediate applications with more complexity, and multilayer PCBs are dedicated to the most stringent high-performance technologies.

At PCBCart, our mission is to empower your innovation and take your projects forward with expert PCB manufacturing. With rich experience in the industry and leading production facilities, we ensure that from simple single-sided boards to advanced multilayer assemblies, the finest quality of the exact specification comes into the customer's hands. Our focused team is determined to help you with the tools and knowledge you need to improve your designs and reach your goals effectively. Contact PCBCart now and let us help you turn these technological ambitions into actual success.

Request for Advanced PCB Assembly & Manufacturing Quote

Helpful resources:

• 4 Layer PCB — When and Why You Need It

• How to Determine the Number of Layers in PCBs

• Single-Layer vs. Multi-layer PCBs: Cost & Performance Comparison

• Full Feature PCB Manufacturing Capabilities

• Prototype vs. Full Spec Production — When to Switch