PCB etching is an important operation in the production of the printed circuit board (PCB), in which the undesirable copper is etched to cement the circuit. Such manifestations as undercutting, over-etching, and irregularity of etching often disrupt the performance and reliability.

PCB Etching: The Basics

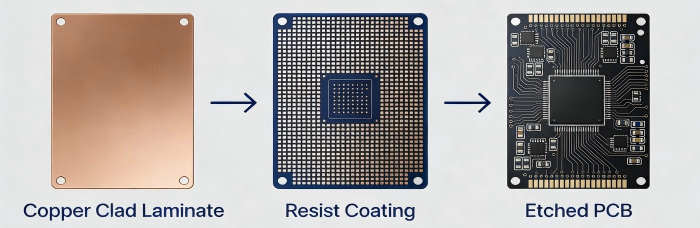

Fundamentally, PCB etching is a chemical operation that is aimed at scraping the unwanted copper in a PCB to achieve precise circuit patterns. An overlay of resist is used to shield passages of copper, with the remaining passages being dissolved in a chemical ether, e.g. ferric chloride or ammonium persulfate. The accuracy of such etching directly relates on the electrical performance, signal integrity and the reliability of the PCB. Such aspects as undercutting, over-etching, and unbalanced etching may result in faulty boards, expensive rework, even possible circuit failures.

Typical PCB Etching Issues and Effect

Knowing how the frequent etching problems affect one is the main way to troubleshoot successfully.

Undercutting

Undercutting is a situation where the etchant can remove copper at the surface and under the resist to form traces which are thinner at the bottom than they are at the top. This weakens the traces.

Causes of Undercutting:

Lack of adhesion of resist: the resist layer must be bonded correctly to the copper or ether will flow under the resist and cause undercutting.

Long etching time: Long exposure to etchant will etch off the copper on the sides of the traces.

Concentrated etchant: The concentrated etchant is too aggressive in copper.

Thin resist layer: Thin resist layers fracture under premature conditions exposing more copper.

Impact of Undercutting:

Weak traces may fracture, or lose their conductivity.

Impedance changes may cause signal degradation particularly in high-frequency circuits.

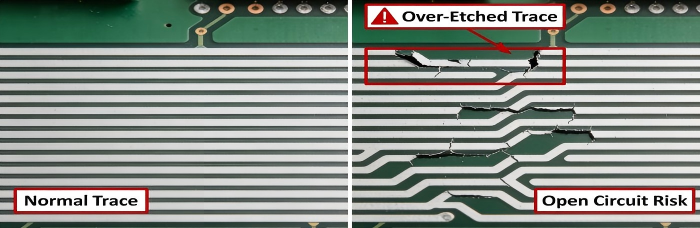

Over-Etching

There is over-etching whereby the etchant removes excessive copper as a result of being exposed too much. This may result in thin traces or open circuits.

Causes of Over-Etching:

Long exposure: copper will over-etch when the PCB is left in the ether too long.

Lack of correct etchant temperature: Increased temperature increases the rate of etching.

Poor etchant mix: Etchant of high chemical concentration removes too fast.

Impact of Over-Etching:

Failure of PCB occurs due to open circuits and broken connections.

Signal distortions, especially in high density layouts, are possible with very thin differences in trace width.

Uneven Etching

Uneven etching This is copper removal unevenly across the board. Certain areas are possible to be over-etched and some under-etched.

Causes of Uneven Etching:

Poor agitation: Some parts of the PCB are not properly stirred because of inadequate agitation.

Uneven resist application: Resist will not be uniformly covered and thus some of the design will be cut off.

Temperature changes: When the etchant temperature changes, the etching rate may become uneven.

Depleted or aged etchant: Worn out etchant will not cut evenly.

Impact of Uneven Etching:

Unstable electric performance results in faulty circuits.

Current distribution of power circuits can be influenced by variation in resistance.

Resolutions and Problem-solving Techniques

The following are practical measures that can be taken to address typical etching errors:

Solutions for Undercutting:

Maximize etching period: Pay attention to the etching. A 1 oz copper layer should normally take 5-10 minutes at 40℃. Test with a sample first.

Enhance resist adhesion: Clean copper surface properly to have good resistance bonding.

Reduce the concentration of the ether: This can be done by diluting the ether to reduce the rate of reaction and reduce undercutting.

Apply a resist layer of greater viscosity: Be sure of an even resist application, and of 1-2 mils thickness.

Solutions for Over-Etching:

Time of control etching: Set a timer and make a check of the board after every 2-3 minutes to prevent excessive exposure.

Optimal etchant temperature: Be sure that the etchant is maintained at 30-40℃ to ensure the same results.

Test etchant strength: It is always important to test the etchant strength on a scrap piece first before actual etching.

Fresh etchant: When the etchant saturates with copper, it is best to change it in order to produce predictable results.

Solutions for Uneven Etching:

Adequate agitation: Pumps, air bubbles or manual stirring will insure the even distribution of the etchant.

Resist Coating: Coat the resist thoroughly, watching out for air bubbles or gaps.

Regulate etchant temperature: regulate temperature of etchant by a thermostat during the process.

Replace old etchant: The etchant should be changed after a certain number of boards had been processed to ensure its effectiveness.

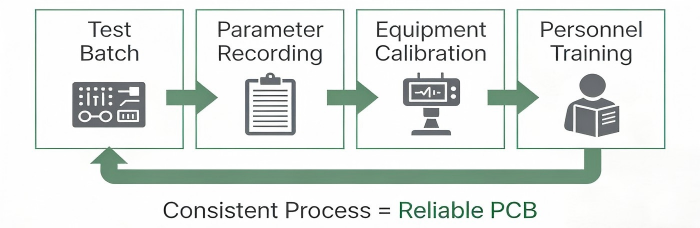

Prevention of Permanent PCB Etching

Prevention, as well as, troubleshooting is also important in ensuring high-quality etching outcomes. The following are the best practices to consider:

Normalize the procedure: Record and repeat the etching parameters (time, temperature, concentration) of each lot.

Work with high quality materials: Spend on quality resist materials and new etchants to minimize variation.

Periodically calibrate equipment: When using heating element, timers and agitation systems, it ensures they are calibrated so that they perform optimally.

Train personnel: All the personnel should be trained on the correct etching techniques and safety measures.

Run tests batches: Run a limited test run prior to full production to optimize your process.

PCB etching errors such as undercutting, over-etching and uneven etching must be properly managed to achieve consistent and high-performance boards. You can personally benefit greatly by learning what caused these problems and putting in place methods to solve them as provided by this guide. The secrets in making sure that your PCBs are of the best quality and reliability consist of precision, consistency, and proactive maintenance.

PCBCart provides the best precision and reliability in terms of quality PCBs. Be it in the complex designs or high volume output production, PCBCart can guarantee consistency and precision in any board thanks to its advanced etching processes. Start your PCB quote now and enjoy a smooth design to delivery process.

Request for High-quality PCB Assembly & Fabrication Quote Now