With the large-scale integration of 5G communication and AI technology, electronic devices are evolving rapidly towards high-speed transmission, high computing power support, and high integration. As the central carrier of electronic devices, the printed circuit board (PCB) directly determines the operating efficiency, signal stability, and long-term reliability of terminal equipment. It has become the underlying hardware foundation for supporting the deployment of key applications such as 5G base stations, AI servers, and intelligent terminals. Faced with the two sides of 5G high-frequency signal transmission requirements and AI high-density computing power demands, PCB technology needs to make breakthroughs in the three basic goals of "low loss, high precision, and strong support" and form an all-around innovation system of materials, processes, and structural design.

I. Transmission of High-Speed and High-Frequency Signals: Bridging AI and 5G's "Signal Bottleneck

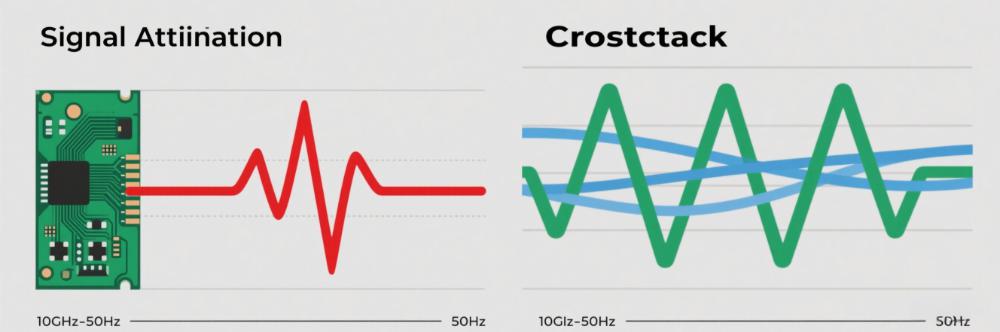

5G communication millimeter-wave frequency bands (26/28GHz) and the 10Gbps+ high-speed interconnect needs of AI equipment place very high demands on the "low loss" and "high stability" of PCB signal transmission. Ordinary PCBs, due to material property and process constraints, cannot meet signal attenuation, reflection, and crosstalk performance in high-frequency applications, thus becoming a key bottleneck restricting the performance of 5G and AI devices.

(I) High-Frequency "Shortcomings" of Ordinary PCBs

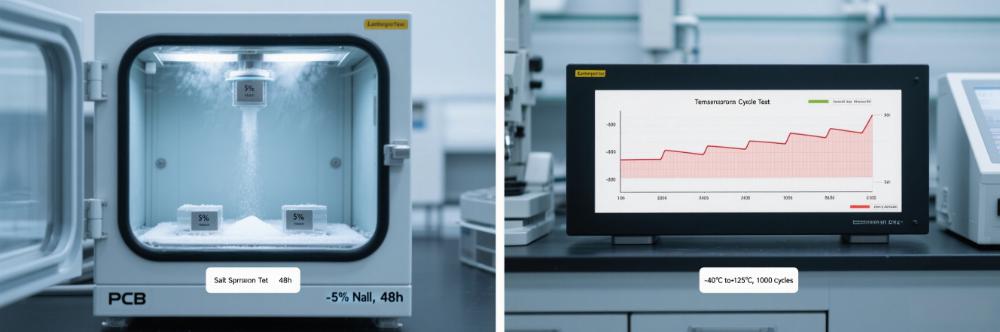

1. Increased Signal Attenuation: High-frequency signals' "skin effect" tends to focus the current at the surface of conductors (the current only spreads out within 5μm of the surface of the copper layer at 10GHz), significantly raising equivalent resistance. Concurrently, the dielectric loss tangent (tanδ) of standard FR-4 substrates measures approximately 0.02 at 10GHz and increases to 0.03 at 28GHz, resulting in more than 60% energy loss for signals traveling more than 10cm, which cannot support the long-distance coverage demands of 5G base stations.

2. Grave Signal Interference: The wavelength of the high-frequency signal is extremely short (the 28GHz millimeter wave wavelength is on the order of 10mm), and minor variation in line length can produce phase shifts. Electromagnetic coupling (crosstalk) among adjacent lines leads to signal "crosstalk". When data transmission speed is 10Gbps, if crosstalk is more than -20dB (10% signal energy coupling), it will directly lead to data transmission errors. Results of testing show that crosstalk of common 10Gbps signal can be up to -15dB, whereas that of 5G and AI-oriented PCBs needs to be kept less than -25dB.

(II) Technological Breakthrough Paths: "Dual Upgrades" of Processes and Materials

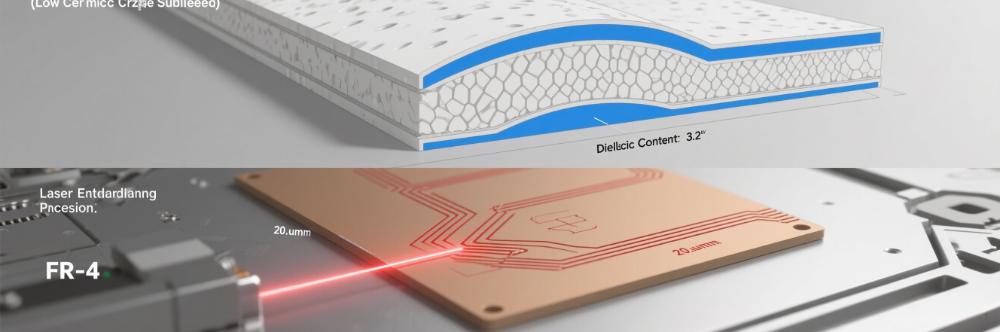

1. Selection of Low-Loss Material: High-frequency ceramic-filled substrates with dielectric constant Dk = 3.0±0.05 are employed. For 5G millimeter-wave micro-base station PCBs, signal transmission loss for the 10GHz frequency range is kept at 0.25dB/in, a 45% decrease compared to traditional FR-4 substrates, and virtually doubling the high-frequency signal transmission distance. At the same time, "very low profile (VLP) copper foil" is used to control the surface roughness (Ra) of 0.3μm, which avoids the "scattering loss" of signal caused by general electrolytic copper foil (Ra≈1.5μm) and reduces the transmission loss of 28GHz signals by 15%-20%.

2. Optimization of High-Precision Processes: One process of "precision impedance control + low-roughness lines" is fixed. Transmission lines are processed using laser etching technology with an edge roughness Ra<0.5μm. The reflection coefficient of the signal (S11) in the 28GHz frequency band is optimized to -30dB, which is 20% better than industry level, to enable undistorted transmission of high-speed 10Gbps signals. In the meantime, laser direct imaging (LDI) technology is used to achieve line width deviation control of ±0.005mm, impedance matching accuracy reaching ±2%, far more superior to the ±10% level of regular PCBs, reducing signal reflection risk from the process side.

(III) Application Effects: Enhancing 5G and AI Devices' Performance

Test results of a 5G base station equipment manufacturer demonstrate that the high-frequency optimized RF module with wider signal coverage and improved rate stability is achieved for 15% broader signal coverage and 30% higher rate stability when multiple users are accessed simultaneously. On the high-speed interconnect links of AI servers, the bit error rate of the 10Gbps signal transmission is reduced from 1e-12 (with common PCBs) to 1e-15, meeting the requirements of low-latency AI real-time data processing.

II. High-Density Integration Design: The "Space Revolution" Enabling AI Computing Capacity

The continuous improvement in the computing power density of AI chips (with the computing power of a single chip running higher than dozens of TOPS) has driven PCBs to develop towards "high density and small size". Standard PCBs are limited by wiring density and chip integration and cannot implement parallel operation on many high-computing-power chips. Advances in integration bottlenecks need structural design breakthroughs.

(I) Core Technological Innovations

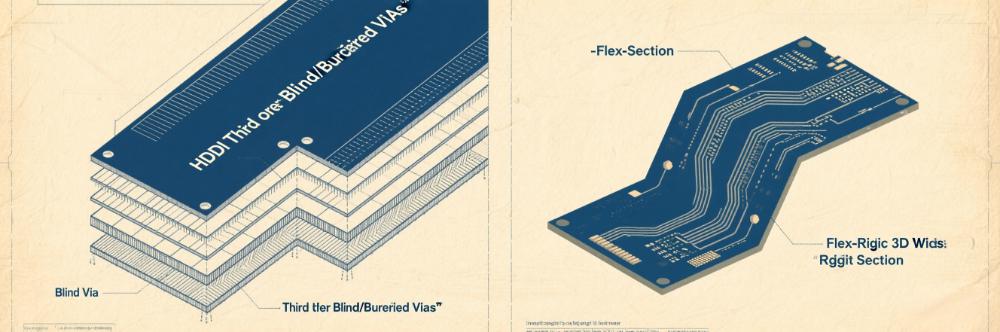

1. HDI Third-Order Blind and Buried Via Technology: Through a 0.1mm microvia processing technology, wiring density in a PCB is increased to 200 lines/cm², 50% more than standard PCBs. In a PCB for an AI accelerator card, this technology supports up to 8 high-computing-power chips without difficulty, enhancing the density of computing power to 20TOPS/cm² and providing high-density computing power support for AI inference tasks.

2. Flex-Rigid Combination + 3D Wiring: 3D wiring structure that connects rigid motherboards through flexible components is employed, reducing connectors by 60%, the signal transmission path by 30%, and controlling the signal delay within 50ns. For intelligent terminal PCBs, this structure not only meets the demand for device thinness and lightness but also ensures the response speed for real-time AI interaction.

In server applications for edge computing, high-density integration technology allocates 40% of the PCB area and supports 16-channel parallel data processing, satisfying the dual demands of "small size and strong computing power" for AI real-time inference and providing a hardware platform for deploying AI in edge scenarios.

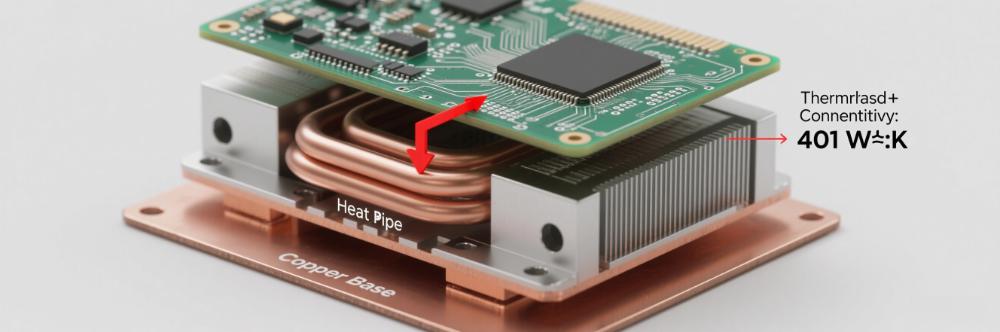

III. Computing Power Support Optimization: Shattering the "Heat Dissipation and Power Supply Dilemma" of AI Equipment

The deep power consumption characteristics of AI equipment (single-chip power consumption of as much as 300W) impose tremendous challenges on heat dissipation performance and power supply stability of PCBs. With delayed heat dissipation, junction temperature of the chip will rise, leading to the decline of computing power; inordinate ripple of the power supply cannot meet the instant power consumption demands of high-computing-power chips. Structure and circuit design need to be optimized simultaneously to overcome the constraints.

(I) Innovation of Heat Dissipation Solutions

A "copper base + embedded heat pipes" composite heat dissipation structure is built, with the thermal conductivity of the PCB enhanced to 5W/(m·K), a 60% rise compared to traditional aluminum substrates. In an AI server PCB, this structure can regulate the chip junction temperature to below 85℃ at an ambient temperature of 40℃, suppressing computing power frequency decline caused by high temperatures.

(II) Optimization of Power Distribution Networks

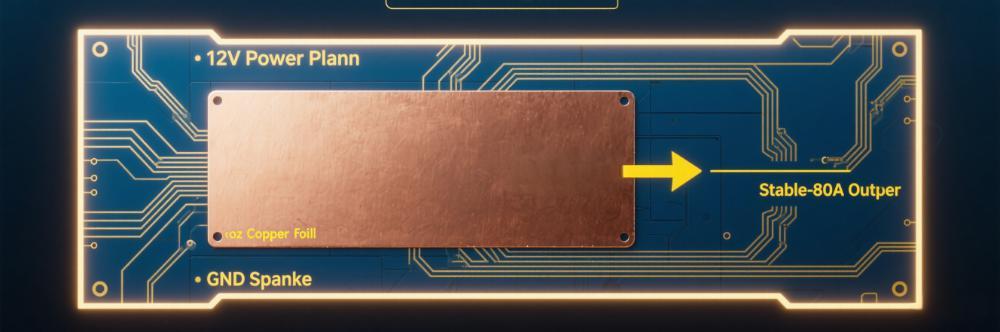

It uses a 2oz thick copper foil and multi-group power plane design to maximize the power distribution network, controlling the ripple of the power supply within ±2% and providing reliable high-current output of 12V/80A. In a PCB AI training card, the solution meets the instantaneous power consumption demands of high-computing-power chips, improving the reliable operation of the training card under long-term high load by 40% and increasing the utilization rate of computing power from 85% to 95%.