In today's ever-evolving world of electronics manufacturing, Surface Mount Technology (SMT) is an innovative technology that has transformed the mounting of electronic components onto printed circuit boards (PCBs). SMT is at the heart of nearly every modern electronic device, enabling manufacturers to produce increasingly tiny and efficient electronic devices, ranging from mobile phones to industrial machinery. For those in industries that rely on precise and sophisticated electronics, having knowledge of SMT is important.

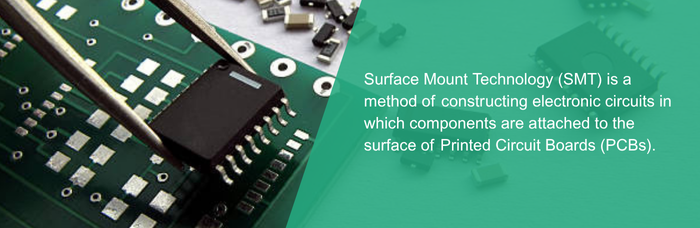

Understanding Surface Mount Technology

Surface Mount Technology (SMT) is a method of constructing electronic circuits in which components are attached to the surface of Printed Circuit Boards (PCBs). The method is used instead of the traditional through-hole technology, under which component leads were threaded into holes drilled onto the PCB. The justification for the change to SMT has been the need for enhanced accuracy, small sizes, and affordability in electronic manufacturing.

Surface-mount devices (SMDs) are components specifically designed for this type of assembly. Components do not require leads to pass through the board, which simplifies manufacturing a great deal and reduces it in terms of labor. Instead, they are assembled onto the surface pads of the PCB, typically by using a process known as reflow soldering.

Background of SMT

The technology of SMT has its roots in the 1960s when IBM was one of the first users to adopt a method then known as Planar Mounting. It was not until the 1980s, however, that SMT gained universal acceptance worldwide, fueled by the shrinkage of electronic components and the demand for more robust, multi-functional electronic products.

By the mid-1980s, surface-mount technology was already overtaking conventional methods; surface-mounted devices had a mere 10% of the market as early as 1986 but their market share rose rapidly. By 1990, the majority of PCB assemblies used SMT owing to its clear superiority over speed, efficiency, and high-density layout capabilities. Some other expressions are also normally associated with surface-mount technology (SMT). They are:

SMD – Surface-mount devices

SMA – Surface-mount assembly

SMC – Surface-mount components

SMP – Surface-mount package

SME – Surface-mount equipment

Advantages of SMT

Miniaturization: One of the most significant benefits of SMT is the ability to produce much smaller components. The miniaturization enables easy manufacture of compact, lightweight devices to be used in handheld units, a crucial factor in today's fast consumer electronics business.

Higher Density and Capabilities: SMT also allows for components to be mounted on the backside of a PCB. This feature greatly increases circuit density, with designers able to include more capability within smaller spaces, with devices thereby being more feature-rich without being larger.

Cost Reduction and Automation: The SMT procedure is highly automated, reducing labor and accelerating production. This automates manufacturing to be more reliable and less costly in terms of labor cost. Also, the lead material reduction results in lower component cost.

Performance Enhancement and Reliability: The components are soldered with short lead length in SMT. This shorter length means less parasitic capacitance and inductance, which contributes to improved high-frequency performance and reliability.

Design Flexibility: SMT provides greater design flexibility, and it can accommodate a mixture of SMT and traditional through-hole components if needed, which is used in hybrid or complex schemes at times.

SMT Manufacturing Process Overview

The production process of SMT can be split into several steps, all significant to providing an effective end product:

SMC and PCB Preparation: The SMCs and the PCB are prepped for assembly. The board contains solder pads – flat and typically tin-lead plated. Smaller, typically silver or gold-plated, pads also exist. These pads aid the mounting of components. Solder paste is directed in its application onto the PCB by using a stencil that corresponds to these pads.

Solder Paste Printing: The solder paste is a mixture of powdered solder metal and flux and is deposited with the assistance of the stencil. The paste temporarily holds components and facilitates easy soldering by cleaning the surfaces and preventing oxidation.

Component Placement: Extremely advanced pick-and-place machines place the SMCs onto the PCB with very high accuracy using vacuum or gripper nozzles. This is a critical step, as any misplaced component can result in defects that are time-consuming and expensive to fix.

Reflow Soldering: After mounting components, the PCB is reflow soldered. The board is put through a reflow oven, where it is heated up gradually, allowing the solder paste to melt and form strong connections between board and components.

Cleaning and Inspection: The PCB is cleaned to remove any flux residues after soldering. It is then subjected to rigorous inspection processes, including Automated Optical Inspection (AOI), X-ray inspection, and other procedures to detect any flaws or defects.

Challenges and Considerations

Even though SMT has numerous advantages, there are certain challenges it faces. The small size of the components can lead to assembly and installation issues. Also, the cost of initial investment in the automation tools along with the technical expertise involved can be very high.

SMT board fixing is also more complex than their through-hole counterparts, with the added complexity of dealing with small and closely packed components. High-precision equipment is required for testing and inspection, which require high educational and financial expense.

Surface Mount Technology (SMT) is a cutting-edge technology that has completely transformed the mounting of electronic components onto printed circuit boards. By directly mounting components onto the surface of PCBs, SMT facilitates the design of electronic devices that are smaller, more efficient, and cheaper. With its high-density arrangements and greater degree of automation, this method of assembly is behind nearly all modern electronics and enables one to move a giant leap in terms of circuit complexity and functionality. As companies ongoingly demand smaller and more intricate technology, SMT will never lag behind in driving these advancements. Keeping pace with the quick rate of technology advancement, knowing and applying SMT is important for all individuals taking part in producing electronics.

At PCBCart, we leverage the benefits of Surface Mount Technology to offer world-class PCB manufacturing and assembly services that are tailored to meet individual customers' specific needs. Our advanced facilities and advanced automation equipment allow us to mass-produce high-density, high-reliability electronic assemblies at competitive prices without a compromise on quality. Our professional personnel is committed to making sure all products are of the finest quality. Whether you're a new enterprise seeking a quick prototype or a corporation requiring a high-volume production order, PCBCart has the capability to fulfill your needs with very high precision and efficiency. Welcome to place a quote with PCBCart today and experience our commitment to excellence in PCB assembly and production.

Start Your Customized SMT Assembly Quote at PCBCart

Helpful Resources

• The Most Essential Facts about Surface Mount Technology (SMT)

• SMT, Surface Mount Technology Assembly

• A Full Understanding of SMT Assembly Procedure Helping YOU Reduce Production Cost

• Essential Elements of SMT Assembly

• Application of Surface Mount Technology (SMT) on Ball Grid Array (BGA) Packages

• Process Control Measures to Stop Defects in SMT Assembly