Power electronics printed circuit boards (PCBs) play a critical role in mission-critical applications such as electric vehicles (EVs), renewable energy systems, industrial machinery, and medical devices. These PCBs must handle excessive voltage, high current, and harsh thermal loads while ensuring reliability, safety, and compliance with international standards.

Compared to standard PCBs, power electronics boards face unique challenges: excessive heat from resistive loss, electromagnetic interference (EMI) from high-frequency switching, and the risk of electrical arcing or component degradation in high-energy applications. Developing robust power electronics PCBs requires an end-to-end design approach, encompassing layout optimization, materials science, component selection, thermal management, and regulatory compliance. This guide integrates PCBCart's engineering expertise and industry best practices to provide a solid framework for designing high-performance, safe, and robust power electronics PCBs.

1. Key Challenges in Power Electronics PCBs

Power electronics PCBs involve the intersection of electrical and thermal performance, where even minor design errors can lead to significant failures. The key challenges are as follows:

· High Power Density: Components like voltage converters, MOSFETs, and IGBTs handle currents exceeding 10 A and voltages ranging from hundreds to thousands of volts, generating substantial heat through I²R losses. Efficient heat dissipation is essential to prevent component degradation.

· EMI and Signal Integrity: The high-switching rate of AC/DC converters creates high di/dt (current vs. time) loops, which radiate and conduct EMI. This interference can disrupt sensitive analog circuits (e.g., sensors) or violate regulatory requirements (e.g., FCC Part 15, CISPR).

· Thermal Stress: Mismatches in the coefficients of thermal expansion (CTE) between PCB materials and components cause delamination, solder joint cracking, or structural failure due to temperature cycling.

· Safety Risks: High-voltage nodes pose electrical shock or arcing hazards, requiring strict insulation (clearance/creepage) and protective components (fuses, TVS diodes).

· Material Limitations: Standard PCB materials such as FR-4 lack the thermal conductivity and voltage endurance needed for high-power applications, necessitating the use of specialized substrates (e.g., ceramics, PTFE laminates).

PCBCart addresses these challenges with customized design tools (e.g., trace width calculators, EMI simulation tools) and design guides, helping engineers minimize risks early in the development phase.

2. Design Methods for the Core Layout of Power Electronics PCBs

Layout design is the foundation of reliable power electronics PCBs, as it directly affects heat distribution, EMI, and power integrity. The following methods integrate three industry perspectives to achieve optimal performance.

2.1 Strategic Component Placement

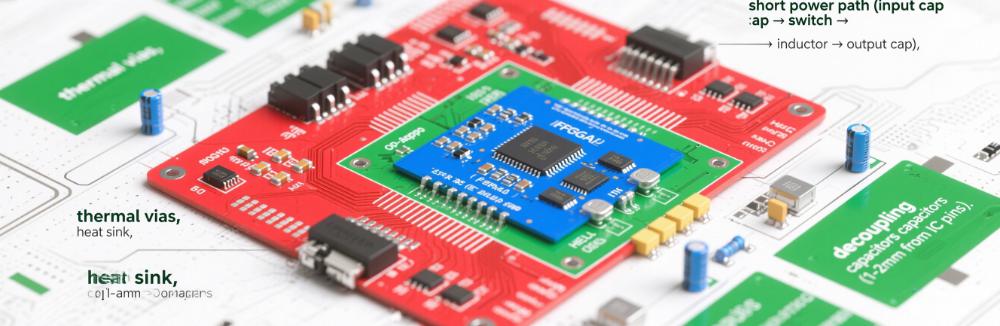

Component placement determines thermal hotspots, trace length, and EMI coupling, making it a top priority in layout design. Key guidelines include:

· Prioritize High-Power Components: Position high-current components (e.g., voltage converters, power transistors, rectifiers) internally (not at board edges) to avoid mechanical stress and enable access to heat dissipation structures. Ensure their associated traces are wide enough to handle rated currents (refer to Section 2.2 for trace width).

· Segregate Heat Sources: Place heat-generating elements (e.g., power MOSFETs, diodes, linear regulators) near heat sinks, thermal vias, or large copper planes to facilitate heat dissipation. Avoid clustering these components (to prevent localized hotspots); use distributed linear placement for uniform thermal diffusion.

· Centralize Digital Components: Highly integrated digital components (e.g., microcontrollers, FPGAs) generate moderate heat and should be located at the PCB center. This position balances heat removal and reduces thermal coupling to sensitive analog circuits (e.g., current sensors).

· Minimize Power Path Lengths: Group power supply components (e.g., input capacitors, DC-DC converter ICs, inductors, output capacitors) as closely as possible. Shorter high-current traces reduce parasitic inductance, which causes voltage spikes and EMI. For example, placing the input capacitor, switch, inductor, and output capacitor on the same layer eliminates impedance discontinuities from vias—PCBCart's Power Electronics Layout Guide includes application-specific examples.

· Segregate Functional Subgroups: Divide the PCB into functional groups (e.g., power conversion, control, sensing) to isolate noise sources from delicate circuits. For instance, place analog control components (e.g., op-amps, Hall-effect sensors) at the edges, using thin traces and dedicated ground planes to minimize interference from high-power paths.

· Optimize Layer Positioning: Place large components (e.g., MOSFETs, electrolytic capacitors) on the top layer to prevent movement during soldering; position small passives (e.g., resistors, ceramic capacitors) on the bottom layer to save space. Avoid placing heavy components (e.g., heat sinks) in ways that stress solder joints.

· Precision IC Decoupling: Position decoupling capacitors (0.1 μF to 10 μF) 1–2 mm from IC power pins and connect them directly to ground. This provides a local energy reservoir for immediate current demand, minimizing power rail ripple and noise. For high-frequency noise (>1 MHz), avoid using vias for decoupling capacitors to prevent parasitic inductance—see PCBCart's Decoupling Capacitor Placement Guidelines for details.

2.2 Optimized Power Trace Design

Power traces are critical for carrying high currents without excessive voltage drop or heating. Poorly designed traces can cause thermal stress, EMI, or component failure. Key guidelines include:

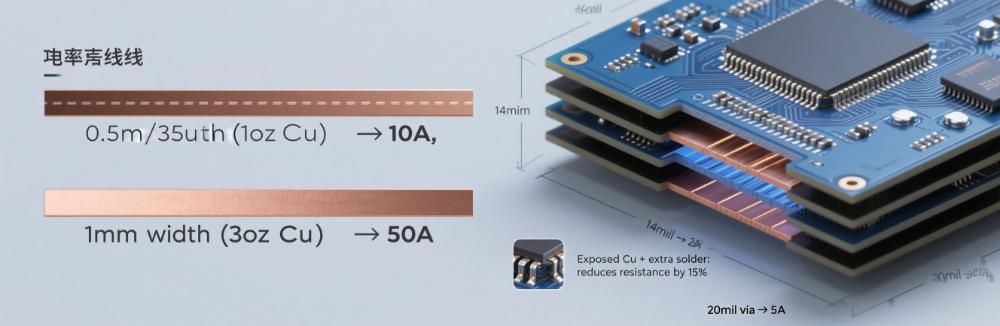

· Select Appropriate Copper Thickness: For currents over 10 A, use copper thicknesses of 35–105 μm (1–3 oz/ft²). Thicker copper reduces resistance (and thus heat) and allows narrower traces—critical for space-constrained designs. PCBCart recommends aligning copper thickness with IPC-2152, which specifies current-carrying capacity based on temperature rise and ambient conditions.

· Size Traces Based on Current Requirements: Trace width must match the expected current to prevent overheating. Benchmarks are

0.5 mm (20 mil) for 10 A

1 mm (40 mil) or greater for 50 A

Always derate trace capacity by 20–30% to account for surge currents (e.g., motor start-up). Table 1 provides additional guidelines for 1 oz/sq ft copper (0.035 mm thick), based on a 10°C temperature rise on outer layers and 20°C rise on inner layers (traces not near heat sinks):

| Trace Width | Current Capacity |

|---|---|

| 0.010″ | 0.8 A |

| 0.015″ | 1.2 A |

| 0.020″ | 1.5 A |

| 0.050″ | 3.2 A |

| 0.100″ | 6.0 A |

PCBCart's Trace Width, Current Capacity and Temperature Rise Calculator simplifies this process, generating custom trace sizes based on current, copper weight, and temperature limits.

· Minimize Parasitic Inductance: Keep power traces as short as possible to reduce loop area—especially in high di/dt circuits (e.g., switching regulators). For example, the "hot loop" of a DC-DC converter (input capacitor → switch → inductor → output capacitor → ground) should be as small as possible to avoid voltage ringing. Route current and return paths together to cancel magnetic fields and reduce EMI.

· Use Outer Layers for High-Current Traces: Outer layers act as more effective heat sinks than inner layers (exposed to ambient air). If outer layer routing is not feasible, use multiple vias to connect copper areas between layers. 14 mil diameter vias can carry up to 2 A, and 20 mil vias up to 5 A; for higher currents, use via stitching (vias λ/20 to λ/10 apart, where λ is the signal wavelength) to create low-impedance paths.

· Prevent Signal-Power Trace Coupling: Run sensitive signal traces (e.g., sensor outputs) perpendicular (90°) to power traces, and separate them with a ground plane in multilayer PCBs. Parallel routing on adjacent layers causes capacitive coupling, degrading signal integrity.

· Upgrade Traces with Exposed Copper: For high-current traces, remove solder mask to expose copper and add extra solder. This increases effective copper thickness, reducing resistance without widening the trace—ideal for space-constrained designs. For harsh environments, add silver plating to exposed copper to resist corrosion.

· Meet High-Voltage Requirements: For voltages over 250 V, use cutouts (grooves or notches) to improve creepage distances between conductive paths, reducing arcing risks. Avoid large holes in high-voltage regions, as they weaken PCB integrity and may cause cracking. PCBCart's PCB Conductor Spacing and Voltage Calculator computes minimum clearance/creepage based on voltage, material, and ambient conditions.

2.3 Capacitor Stabilization of Power Delivery

A stable power delivery network (PDN) is critical for power electronics, as voltage transients or ripples can damage components or disrupt operation. Capacitors are primarily used to stabilize PDNs:

· Bulk Capacitors for Surge Currents: Use bulk capacitors (e.g., electrolytic, tantalum) to supply surge currents (e.g., motor start or IC power-up) and stabilize input voltages. Minimum capacitance is calculated using the equation:C=I×ΔtΔV

where I = surge current, Δt = surge duration, and ΔV = maximum allowable voltage drop. Place bulk capacitors near high-current components (e.g., MOSFET inputs, sense resistor outputs) to minimize trace length.

· Bypass Capacitors for Noise Filtering: Use bypass capacitors (e.g., 0.1 μF ceramic) near IC power pins to filter high-frequency noise. For multi-frequency systems, combine capacitor values (e.g., 10 μF for low frequency, 0.1 μF for high frequency) to cover a broader noise spectrum.

· Low ESR Capacitors for High Frequencies: Select capacitors with low equivalent series resistance (ESR) to minimize power losses at high switching frequencies. Ceramic capacitors (X5R, X7R dielectrics) are ideal, with ESR as low as 10 mΩ. Avoid wet tantalum capacitors in high-voltage circuits (vulnerable to catastrophic failure under overvoltage)—use niobium capacitors as a safer alternative.

2.4 Ground Plane Design for Noise Reduction

Ground planes reduce noise, establish low-impedance return paths, and aid heat dissipation. Key design principles include:

· Use Solid Ground Planes: Employ uninterrupted ground planes (instead of scattered traces) to achieve lower impedance for high-return currents. Solid planes also help remove heat from heat-sensitive devices (e.g., power transistors).

· Separate Power and Signal Grounds: Use a dedicated ground plane for power circuitry, connected to the system ground at a single point (star grounding). This prevents power noise (e.g., from switching regulators) from coupling into sensitive analog circuits.

· Dual-Side Ground Planes: In multilayer PCBs, use ground planes on both top and bottom layers to absorb radiated EMI and reduce ground loop noise. Connect these planes with vias to ensure electrical continuity.

· Optimize Ground Planes for High-Current Paths: Arrange ground planes with high-current power traces in a "sandwich" to reduce parasitic inductance and EMI. For example, route a power trace on the top layer and its return path on the adjacent ground plane to cancel magnetic fields.

3. Critical Material Selection for High-Power PCBs

Material selection directly impacts thermal performance, voltage tolerance, and mechanical reliability. Power electronics PCBs require materials that outperform conventional FR-4 (which has lower thermal conductivity and voltage tolerance).

3.1 Substrate Material Selection Criteria

The PCB substrate (laminate) forms the basis of electrical and thermal performance. Key parameters to evaluate are:

Thermal Conductivity (K): Measures a material’s heat conduction ability. For high-power designs, select substrates with K>1 W/m-K. Examples include:

- Rogers RT laminates (1.44 W/m-K): Ideal for high-power designs due to superior thermal management and low dielectric loss.

- Ceramics (alumina, aluminum nitride): Offer K values up to 200 W/m-K but are brittle and more expensive.

- PTFE laminates (Teflon): Provide good thermal conductivity and voltage withstand, suitable for high-frequency power circuits.

- Avoid FR-4 (K≈0.25 W/m-K) in high-power applications, as it inhibits heat dissipation.

Glass Transition Temperature (Tg): The temperature at which the substrate softens. Select substrates with Tg≥20∘C above the PCB’s maximum operating temperature. For example, if the PCB operates at 170°C, choose a substrate with Tg≥190∘C. Substrates like Pyralux AP, Nelco N7000-2HT, and ISOLA 370HR meet this requirement.

Coefficient of Thermal Expansion (CTE): Ensure the substrate’s CTE matches that of components (e.g., copper, silicon) to avoid mechanical stress during temperature fluctuations. Mismatched CTE can cause delamination or solder joint failure. For example, Rogers laminates have a CTE of ~14 ppm/°C (x-y axis), nearly matching copper’s 17 ppm/°C.

Comparative Tracking Index (CTI): Characterizes a material’s resistance to electrical tracking (surface current leakage). High-voltage applications require materials with high CTI values to prevent arcing. CTI is classified into groups (Table 2):

| CTI Group | CTI Range (V) | Typical Materials |

|---|---|---|

| I | ≥ 600 | PTFE, Ceramics |

| II | 400–599 | High-performance laminates |

| IIIa | 175–399 | FR-4 |

| IIIb | 100–174 | Low-cost laminates |

PCBCart's PCB Material Design Guide provides detailed CTI information for substrates, enabling engineers to select materials that meet voltage requirements.

Resin Content and Glass Weave: High-voltage applications require high resin content substrates (>50%) and fine glass weaves (e.g., 1080, 2113, 2116). Minimizing voids (air pockets) between layers reduces the risk of conductive anodic filamentation (CAF)—a copper electromigration failure mechanism in humid conditions. Fine glass weaves improve resin penetration, further lowering CAF risk.

Curing Agents: For high-voltage applications, use substrates with phenolic curing agents (instead of dicyandiamide, DICY). Phenolic agents offer better CAF inhibition, while DICY-based materials—though having higher Tg—are prone to failure under high voltage gradients.

3.2 Copper Thickness and Weight Optimization

Copper is the primary conductor in PCBs, and its thickness directly affects current-carrying capacity and heat dissipation. Key guidelines include:

· Copper Thickness for Current Requirements: As discussed in Section 2.2, 1 oz/ft² (35 μm) copper suffices for currents below 10 A, while 3 oz/ft² (105 μm) copper handles currents above 30 A. For high-current powertrain applications (e.g., EV powertrains), PCBCart offers heavy-copper PCBs (up to 12 oz/ft²) for enhanced performance.

· Copper Thickness and Thermal Dissipation: Thicker copper dissipates heat better than thinner copper. For example, a 2 oz/ft² copper trace dissipates 30% more heat than an equivalent-width 1 oz/ft² trace.

· Inner vs. Outer Layer Copper: Use thicker copper on outer layers (exposed to air) to maximize heat dissipation. Inner layers can use thinner copper, as they rely on thermal vias to transfer heat to outer layers.

4. Component Choice Best Practices in Power Electronics

Component selection is critical for maximizing efficiency, reducing heat, and ensuring safety. The following guidelines integrate insights from three industry perspectives to help engineers make informed decisions.

4.1 Power Supply Components

Power supplies are the backbone of power electronics PCBs, and selection depends on application requirements (e.g., efficiency, noise, power density).

Linear Power Supplies for Noise-Critical Uses: Linear regulators (e.g., LDOs) have low EMI and are ideal for low-power, noise-sensitive applications (e.g., medical devices, laboratory equipment). However, they are inefficient (<60% at high voltage drops), generate significant heat, and are not suitable for high-power use. Key design recommendations:

- Choose LDOs with low thermal resistance (θJA<50∘C/W) to prevent overheating.

- Place temperature-sensitive components (e.g., sensors) away from linear regulators.

- Use an input filter capacitor to dampen power supply noise.

Switched-Mode Power Supplies (SMPS) for High Efficiency: SMPS (buck, boost converters) achieve efficiency >90% by rapidly switching components on/off, reducing resistive losses. Suitable for high-power applications (EV chargers, industrial power supplies) but radiate more EMI than linear regulators. Critical design recommendations:

- Use solid ground planes and shielding to limit EMI.

- Select gate drivers with appropriate current capability to support SMPS switching speeds.

- Add input/output filters (e.g., LC filters) to reduce ripple voltage and conducted EMI.

DC-DC Converters for Voltage Regulation: DC-DC converters adjust voltage levels (step-up/step-down) in portable devices (e.g., smartphones) and automotive applications. Select converters based on:

- Topology: Buck (step-down) for lower voltage needs (e.g., 12V to 5V), boost (step-up) for higher voltage (e.g., 3.7V to 12V), or buck-boost for a wide voltage range.

- Efficiency: Choose converters with efficiency >95% at full load.

- Switching Frequency: Higher frequencies (e.g., 1 MHz) allow smaller inductors/capacitors but increase EMI.

PCBCart's Component Selector Tool enables engineers to compare power supply components based on efficiency, voltage range, and package size.

4.2 Switches, Diodes, and Semiconductors

Switches and diodes control power flow in circuits, and their selection directly impacts efficiency and heat generation.

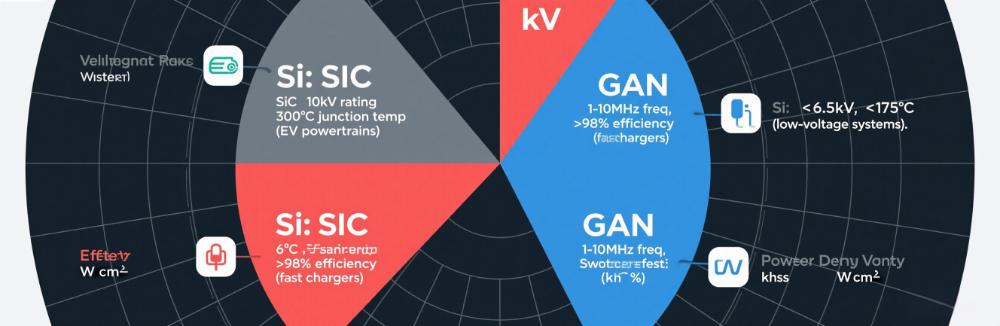

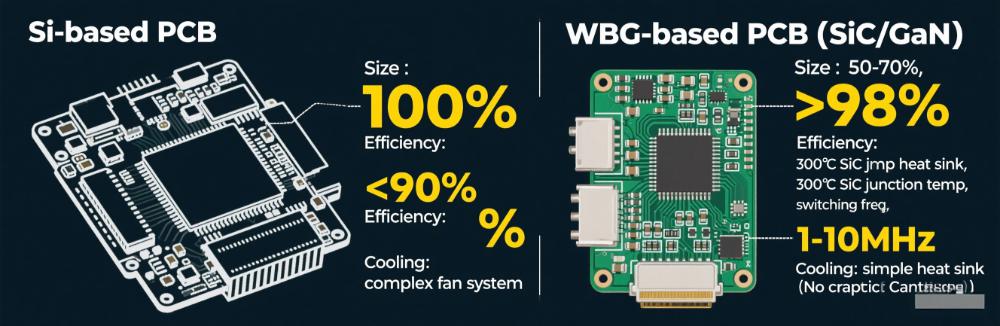

· Semiconductor Materials: Choose between silicon (Si), silicon carbide (SiC), and gallium nitride (GaN) based on application requirements (Table 3):

| Parameter | Silicon (Si) | Silicon Carbide (SiC) | Gallium Nitride (GaN) |

|---|---|---|---|

| Voltage Rating | Up to 6.5 kV (IGBTs) | Up to 10 kV | Up to 650 V (commercial), 1.2 kV (industrial) |

| Temperature Tolerance | Up to 175°C (junction) | Up to 300°C (junction) | Up to 200°C (junction) |

| Switching Frequency | Low (10–100 kHz) | Medium (100 kHz–1 MHz) | High (1–10 MHz) |

| Efficiency | Moderate (<90% at high power) | High (>95% at high power) | Very High (>98% at high frequency) |

| Applications | Low/medium-voltage systems (e.g., 12V automotive) | High-voltage systems (e.g., EV powertrains, solar inverters) | High-frequency systems (e.g., fast chargers, data centers) |

Si: Cost-effective for low-voltage, low-power designs but limited in frequency and temperature.

SiC: Used in high-temperature, high-voltage designs (e.g., EVs, industrial drives) due to its high voltage handling and thermal resistance.

GaN: Used in high-frequency, high-density applications (e.g., 65W laptop supplies) due to minimal losses and high switching frequency.

Switches: Select switches based on voltage rating, current handling, and switching speed:

- MOSFETs: Suitable for low-to-medium voltage (up to 1 kV) and high-frequency applications. Choose MOSFETs with low on-resistance (Rds(on)<100 mΩ) for low conduction losses.

- IGBTs: Ideal for medium-to-high voltage (up to 6.5 kV) and high-current applications (e.g., industrial motors). They combine the low on-resistance of MOSFETs with the high voltage rating of bipolar transistors.

- GaN FETs: Faster switching and lower losses than Si MOSFETs, making them suitable for high-frequency power supplies.

Diodes: Choose diodes based on forward voltage drop, reverse recovery time, and voltage rating:

- Schottky Diodes: Low forward voltage drop (0.2–0.5 V) and fast reverse recovery time (<10 ns), ideal for high-frequency rectification.

- SiC Diodes: High voltage rating (up to 10 kV) and thermal resistance, best for high-power rectification (e.g., EV chargers).

- TVS Diodes: Transient voltage suppressor (TVS) diodes clamp voltage spikes (e.g., from ESD) to protect sensitive components. Select TVS diodes with a breakdown voltage slightly higher than the maximum operating voltage.

4.3 Capacitors and Inductors

Inductors and capacitors store and transfer energy in power circuits, and their selection affects efficiency and noise.

Capacitors:

- Ceramic Capacitors: Used for high-frequency filtering (0.1 μF) and bypassing. Choose X5R or X7R dielectrics for thermal stability (-55°C to 85°C or 125°C).

- Electrolytic Capacitors: Ideal for bulk energy storage (e.g., 100 μF to 10 mF) in low-frequency applications. Select long-life options (e.g., 10,000 hours at 105°C) for industrial use.

- Film Capacitors: Low ESR and high voltage rating (up to 10 kV), suitable for high-power motor drives and inverters.

Inductors:

- Low DCR Inductors: Select inductors with low DC resistance (DCR) to minimize power losses. Toroid inductors are preferred for low EMI and high efficiency.

- Shielded Inductors: Used in EMI-sensitive applications (e.g., medical devices) to reduce radiated noise.

- Inductance Value: Calculate required inductance based on ripple current and switching frequency. For example, a 1 μH inductor is suitable for a 1 MHz buck converter with 10% ripple current.

4.4 Resistors, Fuses, and Protection Devices

Protective devices shield components from overcurrent, overvoltage, or ESD failure.

Resistors:

- Current-Sense Resistors: Use precision resistors (tolerance <1%) and low TCR (<50 ppm/°C) for accurate current measurement. Select resistors with a power rating 2–3 times the expected dissipation (P=I2R).

- Wirewound Resistors: Used in high-power applications (up to 100 W) due to high power density.

- Metal-Film Resistors: Used in high-frequency circuits (up to 100 MHz) due to low parasitic inductance.

Fuses:

- Fast-Acting Fuses: Used in low inrush current circuits (e.g., digital ICs) to prevent short circuits.

- Slow-Blow Fuses: Used in high inrush current circuits (e.g., motors, transformers) to avoid false tripping.

- Rating Considerations: Use fuses with voltage ratings higher than the circuit’s maximum operating voltage and current ratings 1.25x the normal operating current.

Other Protection Devices:

- Varistors: Offer nonlinear resistance that limits surge currents (e.g., from lightning) as voltage increases.

- ESD Protection Diodes: Protect sensitive components (e.g., ICs) against ESD events (up to 15 kV contact discharge).

4.5 Sensors, Drivers, and Connectors

Sensors and drivers manage and monitor power flow, while connectors enable reliable power/signal transfer.

Sensors:

- Current Sensors: Use Hall-effect sensors for non-invasive current sensing (up to 1000 A) or shunt resistors for precise low-current sensing (up to 100 A).

- Temperature Sensors: Incorporate NTC thermistors or digital sensors (e.g., I2C-based) to monitor PCB temperature and trigger thermal shutdown if limits are exceeded.

Drivers:

- Isolated Gate Drivers: Used in high-voltage designs (e.g., SiC MOSFETs) to isolate low-voltage control signals from high-voltage power paths. Optocoupled or transformer-isolated drivers are common.

- Bootstrap Drivers: Suitable for low-voltage designs (e.g., 12V automotive) to drive high-side MOSFETs without an isolated power supply.

Connectors:

- Current Rating: Select connectors with appropriate maximum current ratings (e.g., 30 A for EV charging ports). Use gold or silver-plated connectors for low resistance and corrosion resistance.

- Locking Mechanisms: Use connectors with secure locking (e.g., screws, latches) to prevent accidental disconnection in vibrating environments (e.g., automotive, industrial machinery).

- Environmental Rating: For harsh environments, use connectors with IP65 or higher ratings to protect against dust and moisture.

PCBCart's Connector Design Guide provides detailed recommendations for selecting connectors based on current, voltage, and environmental conditions.

5. Advanced Thermal Management Approaches

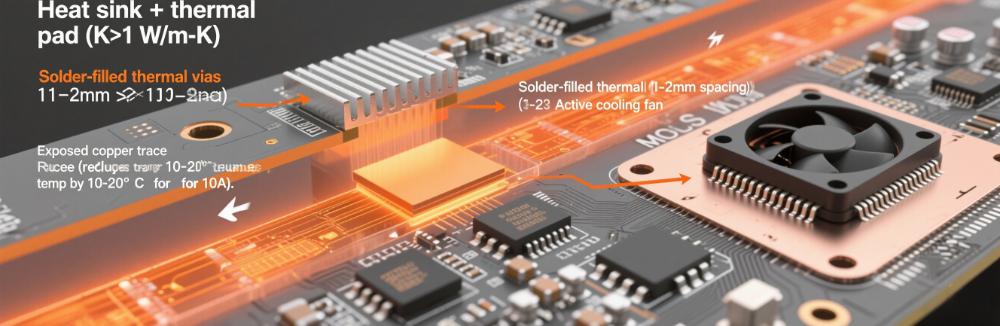

Thermal stress is the primary failure mechanism for power electronics PCBs, making thermal management a key design stage. The following approaches integrate insights from three industry perspectives to maximize heat dissipation:

· Heat Sinks and Thermal Pads: Mount heat sinks on high-power components (e.g., MOSFETs, IGBTs) using thermal pads or thermal paste (thermal conductivity >1 W/m-K). Size heat sinks based on heat dissipation requirements—larger heat sinks for components dissipating >10 W.

· Thermal Vias: Use thermal vias (solder-filled or copper-filled) to distribute heat from hotspots (e.g., power transistor pads) to inner or outer copper planes. Space vias 1–2 mm apart for optimal heat transfer.

· Active Cooling: For high-power designs (>50 W dissipation), use fans or liquid cooling systems. Mount fans on enclosures and power them directly from the input AC signal (for AC/DC converters) or PWM signals (for DC/DC converters) to adjust speed based on temperature.

· Exposed Copper and Solder Mask Removal: Remove solder mask from high-current traces and add extra solder. This technique can reduce trace temperature by 10–20°C for 10 A currents.

· Bus Bars: Use copper or aluminum bus bars to transfer heat from high-power components (e.g., capacitors, inductors) to heat sinks. Bus bars offer high thermal conductivity and low impedance, suitable for currents >100 A.

· Thermal Insulation of Sensitive Parts: Insulate sensitive components (e.g., sensors, op-amps) with materials like polyimide films to prevent thermal variation from affecting performance.

6. EMI Reduction Techniques for Power Electronics PCBs

EMI from high-frequency switching can disrupt sensitive circuits and prevent regulatory compliance. The following techniques reduce EMI:

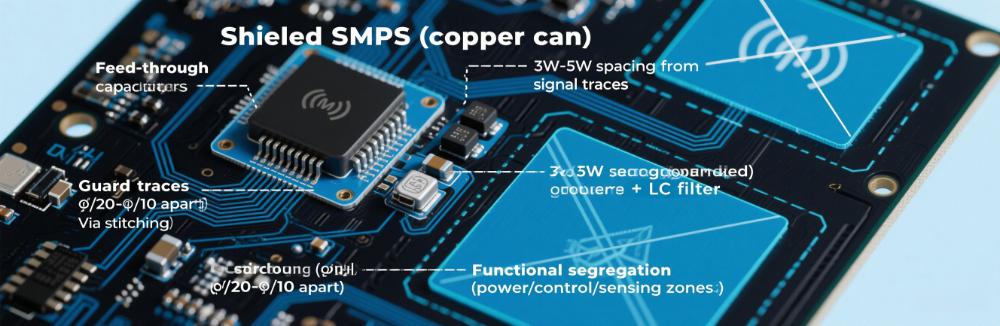

· Shielding: Shield noise sources (e.g., SMPS) using conductive materials (e.g., copper cans, conductive coatings). Properly ground shields to avoid resonance. Use a Faraday cage to enclose electromagnetic fields in sensitive areas.

· Filtering: Place feed-through capacitors or LC filters at power supply input/output to filter conducted EMI. Use common-mode chokes to suppress common-mode noise (e.g., from ground loops).

· Guard Traces: Route guard traces (ground-connected copper strips) around noise-sensitive signals (e.g., sensor outputs) to protect against noise. Maintain 3W–5W spacing between guard traces and signal traces (where W = signal trace width).

· Via Stitching: Use via stitching (grounded vias near PCB edges) to provide a low-impedance path to ground, reducing radiated EMI. Space vias λ/20 to λ/10 (λ = signal wavelength) for optimal performance.

· Circuit Segregation: Divide the PCB into functional regions (power, control, sensing) to isolate noise sources from sensitive circuits. Use ground planes to electrically separate these regions.

7. Industry Standards Compliance

Power electronics PCBs must comply with international standards to ensure safety, reliability, and interoperability. Key standards include:

IPC Standards:

- IPC-2221: Provides PCB design guidelines (e.g., clearance/creepage distances, trace width, component placement)—critical for preventing ESD and electrical arcing.

- IPC-2152: Defines trace current-carrying capacity based on copper weight, temperature rise, and ambient conditions—essential for high-power designs.

- IPC-6012: Specifies PCB fabrication quality requirements (e.g., dielectric strength, solderability, thermal performance).

- IPC-A-600: Establishes visual acceptance criteria for PCBs to promote manufacturing consistency.

UL/IEC Standards:

- UL 60950-1 / IEC 60950-1: Safety standards for information technology equipment, specifying insulation requirements and fault current limits.

- UL 1950 / IEC 60950: Similar to UL 60950-1 but applicable to a broader range of electronic equipment.

- IEC 61800: Requirements for adjustable-speed electrical power drive systems, including EMI and safety requirements for motor drives.

EMI Standards:

- FCC Part 15: Regulates radiated and conducted EMI for electronic products marketed in the United States.

- CISPR 22: European EMI standard for information technology equipment, compliant with FCC Part 15.

PCBCart offers compliance testing to verify PCB adherence to these standards, including EMI/EMC testing, thermal cycling, and dielectric strength testing.

8. Safety Precautions for High-Energy Circuits

High-energy circuits (e.g., EV powertrains, industrial inverters) pose significant safety risks and require additional design protections:

· Clearance and Creepage: Maintain minimum clearance (air gap between conductors) and creepage (surface distance between conductors) per IPC-2221 and IEC 60950-1. For example, 2 mm clearance/creepage for 250 V AC circuits.

· Insulation Materials: Use high-CTI materials (e.g., CTI ≥ 600) for high-voltage circuits to prevent electrical tracking. Apply conformal coating (e.g., acrylic, silicone) to protect against moisture, dust, and accidental contact.

· Safe Discharge Paths: Provide low-resistance paths to discharge stored energy in capacitors, inductors, and batteries. Use bleed resistors (e.g., 1 MΩ) to discharge capacitors within 1 second after power-off.

· Enclosure Design: Select enclosures meeting UL/IEC safety standards (e.g., flame-retardant plastics, metal enclosures). Ensure enclosures have adequate ventilation (e.g., vents, fan mounts) for heat management and an IP rating of IP65 or higher for harsh environments.

· Onboard Safety Features: Implement temperature sensors to trigger thermal shutdown if PCB temperature exceeds safe levels (e.g., 150°C). Add fuses at high-current outputs to protect against short circuits.

9. Emerging Technologies: Wide-Bandgap Semiconductors

Wide-bandgap (WBG) semiconductors (SiC, GaN) are transforming power electronics by outperforming conventional Si devices. Key improvements include:

· Higher Efficiency: WBG devices minimize switching and conduction losses, enabling power supplies with efficiency >98% (compared to <90% for Si).

· Smaller Form Factor: Higher switching frequencies allow smaller inductors, capacitors, and heat sinks, reducing PCB size by 30–50%.

· Higher Temperature Tolerance: SiC and GaN support junction temperatures up to 300°C and 200°C, respectively, eliminating the need for complex cooling systems.

WBG semiconductors are increasingly used in EVs (SiC in powertrains), fast chargers (GaN in 65W+ designs), and solar inverters (SiC in high-voltage DC systems). PCBCart's High-Speed PCB Design Guide provides insights into designing with WBG semiconductors, including layout optimization for high-frequency switching.

10. Conclusion

Power electronics PCB design requires balancing electrical performance, thermal management, EMI containment, and safety. By integrating strategic layout design, material selection expertise, and component optimization, engineers can create boards capable of withstanding the demands of high-power applications (EVs, renewable energy, industrial equipment). Key takeaways include:

· Prioritize component placement to avoid thermal hotspots and minimize trace length.

· Select materials with high thermal conductivity, Tg, and CTI for reliability in high-power environments.

· Choose WBG semiconductors (SiC, GaN) for high-efficiency, high-frequency applications.

· Adopt aggressive thermal management (heat sinks, thermal vias, active cooling) to prevent component failure.

· Comply with IPC, UL/IEC, and EMI standards for safety and regulatory approval.

PCBCart supports engineers throughout the design process with tools (trace calculators, part selectors), design guidelines, and compliance testing services. By following these guidelines and leveraging PCBCart's expertise, engineers can design reliable, efficient, and safe power electronics PCBs.

Get Your Power Electronics PCB Quote

Helpful resources:

• How to Select Material for Your PCBs from Cost and Reliability Considerations

• Essential Elements to Ensure Quality in SMT Assembly Process

• Electrical Test Standards and Methods for PCB Quality Verification

• PCB Certifications: Compliance Requirements for Safe and Reliable Products

• A Guide to Medical PCB Fabrication and Assembly

• PCB Materials: Selection Criteria and Performance Characteristics

• Common Defects in PCB Assembly and How to Prevent Them

• Full Turnkey PCB Assembly