In the world of electronics where time is of the essence, speed and accuracy are fundamental factors in going from a concept to a product that can be launched in the market. The success factor for this process is PCB fabrication and assembly. The need to create flawless prototypes within a short time period has made turnkey prototype PCB manufacturing and assembly services critical to companies wanting to accelerate product development.

Understanding Turnkey PCB Assembly

The term "turnkey" refers to an end-to-end model of service where the whole project is undertaken with the support of a single provider and receives a ready-to-use product at the end. For the PCB assembly example, this translates into component procurement, manufacturing, and complete testing of PCBs. Turnkey PCB assembly applies advanced cloud-based software and robust manufacturing networks and offers small and medium-sized enterprises a cost-efficient, effective way of PCB creation.

Advantages of Turnkey Solutions

Seamless Efficiency: Turnkey solutions consolidate design, procurement, fabrication, assembly, and testing under one roof. This eliminates much complexity and compresses the time from concept to production-ready board.

Cost-Effectiveness: With one service provider, companies get best prices on components and reduced logistics costs, which help contain project expenses within limits.

Systematic Quality Control: Strict testing and quality control measures eliminate errors, and finished products are to design specifications without rework.

Focus on Core Competencies: Turnkey services allow companies to devote resources to product innovation and design with the assembly and fabrication logistics handled by the specialists.

Fast Turnaround: With tech-focused markets, rapid lead times are necessary in order to gain competitive edge, and turnkey solutions provide the functionality to bring innovations to market timely.

PCBCart: Your Best Turnkey PCB Assembly Partner

At PCBCart, we understand the critical role played by the correct PCB manufacturing and assembly in the product development process. Being a leading turnkey PCB assembly services company, we specialize in delivering high-quality products from prototype levels to high-volume production. We focus on small to medium volume manufacturing with flexible minimum orders, with consistent service dedicated to you.

Our Expertise and Services

With large amounts of experience in PCB assembly using mixed technology, through-hole, and surface-mount, PCBCart can handle various project requirements. Our service offerings include:

Quick-Turn Prototype Assembly: A program to facilitate fast prototype board delivery, to support iterative design flows that are so important to innovation.

Full and Partial Turnkey Assembly: We offer scalable levels of service, from full turnkey where we take care of the entire process, to partial turnkey for businesses that want to retain control over some aspects.

In-Depth Component Sourcing and Management: From procurement of parts to final shipping, PCBCart handles the entire supply chain process so you can focus on your main business processes.

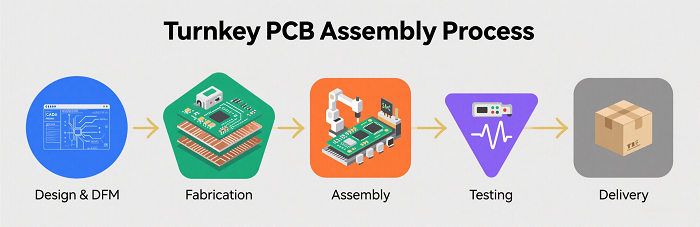

Turnkey PCB Assembly Process

Design and Consultation: It starts with a consultation where we talk about your designs and needs. Our experienced staff can assist with design for manufacture (DFM) to optimize production efficiency.

Online Quotes: Obtain real-time quotes on PCB production using our online quote tools. This provides the accessibility of rapid-turn prototypes and production runs, with transparency and ease of making quick decisions.

BOM Submission and Price: Provide us with your Bill of Materials (BOM) submission. We respond to you with a price breakdown commonly within 24 hours, so you are fully aware of the cost involved in the components.

Fabrication and Assembly: Once the design and components are decided, we proceed with fabrication, using sophisticated facilities and tools to ensure accuracy and quality.

Testing and Verification: Thorough testing is performed to guarantee the assembly quality and reliability of the assembled PCBs, ensuring they meet the high quality standards that your end customers demand.

Delivery and Support: Assembled PCBs are shipped and delivered to your destination. Our support does not end with delivery—we provide extended customer support to respond to any questions or issues that come up after shipping.

Why Choose PCBCart?

PCBCart stands out in electronic manufacturing by making the process of developing PCBs as easy as possible. We eliminate the inconvenience of dealing with multiple component vendors since we provide full service, which ensures that every step of the process is given exactness and care.

For a quote, for an inquiry, or just to talk about your project needs, don't hesitate to reach out to our expert team. Here at PCBCart, we're dedicated to delivering the high quality and efficiency that are necessary for achievement in today's competitive electronics market. Let us work with you to bring your innovative products to life.

Request for Turnkey PCB Assembly & Manufacturing Quote Now

Helpful resources:

• What is Turnkey PCB Assembly

• Prototype PCB Benefits

• PCB Manufacturing Process — A Step-by-Step Guide

• How Much Does PCB Assembly Cost

• Printed Circuit Boards Assembly (PCBA) Process