The choice of solder mask color represents a very important decision in the complex world of PCB design and fabrication-one that goes far beyond mere surface cosmetics. This selection greatly influences the performance, inspection process, and aesthetic look of a PCB. Green has traditionally been the industry’s default color, but like most facets of technology, its evolution has brought significant new solder mask colors into the menu, each with its unique set of advantages that can be targeted to specific applications.

The Role of Solder Masks in PCB Design

A solder mask is an epoxy-based protective layer applied to the surface of a PCB. Among its major functions are the prevention of solder bridges, corrosion resistance, and protection of copper traces from environmental damages. More than that, the color of solder mask plays a critical role in many operational aspects of PCB, impacting both human and automated visual inspections and the performance of signals.

Common Solder Mask Colors and Their Characteristics

Green: The Industry Standard

Green is by far the most applied solder mask color and has remained the standard for the industry because of its perfect contrast to copper traces and solder pads. The high contrast enables better ease and accuracy of visual inspections-both manual and automated. AOI systems mostly working with red light perform well when green masks are deployed on the boards due to their clarity, which comes as an added advantage. Beyond this, green is widely used, which makes it economical because manufacturing processes become streamlined by ensuring availability and consistency.

Blue: Ideal for high-frequency applications

Blue solder masks are also gaining popularity for use in high-frequency applications due to excellent dielectric properties. Blue masks reduce noise and crosstalk, which are critical considerations for boards with signals operating in the GHz range.These characteristics ensure superior signal integrity, a condition particularly important in RF and microwave applications. The clarity blue provides in these settings makes it a popular choice among designers concerned about both signal performance and reliability.

Red: Improved Inspection Visibility

Red solder masks are usually used when rigid inspection and quality control are necessary. High contrast allows the detection of minimal flaws and particulates easily with red masks, which makes them perfect for aerospace, military, and high-reliability medical purposes. The distinct visual advantage of red masks helps in maintaining the strict standards required in these sectors where precision and safety are of utmost importance.

Yellow: High Visibility for Prototyping

Yellow solder masks have the added advantage of their bright color, providing better visibility for tracing and etching inspection, and are well-suited for prototypes or small production runs where much is done visually. Yellow provides a clear, vibrant backdrop to assist technicians and engineers in thorough evaluation during those critical early stages in development.

Black: Emissions Control and Stylish Design

Black solder masks are unique not only in aesthetic respect but also in functional features promoting the control of emissions. The dark color reflects minimal light and, when scattered signals are absorbed, it greatly minimizes EMI/RFI. Such qualities make black masks suitable for automotive, aerospace, and consumer electronics applications that require regulatory compliance with emissions standards. Additionally, the stylish and modern look of black masks makes them favored in consumer products where aesthetic appeal is just as significant as functionality.

White: Best Serving High-Contrast Needs

White solder masks are especially useful for LED applications since they can provide maximum contrast to the substrate of the board. The reflectivity and diffusing properties of white masks enhance brightness and visibility, both of which are critical for ensuring the efficiency of lighting applications. Their high contrast further enhances the effectiveness of AOI systems, crucial in quality control and assurance processes.

Purple: A Unique and Professional Choice

While less frequent, purple solder masks carry an appealing look that is fast becoming useful in the military and aerospace industries.Colors such as RAL 4010 telemagenta allow for a professional finish that aligns well with the branding of higher technology applications. The distinctive nature of the purple mask serves to enhance visual inspection while providing an appearance that can be characterized as high-tech and sophisticated.

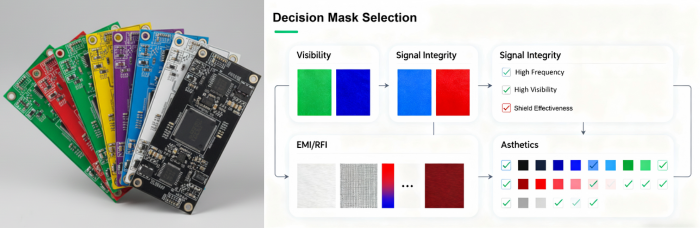

Factors to Consider in Solder Mask Color Selection

Visibility and Inspection: The selection of solder mask color mainly depends on ensuring good contrast visually with the PCB substrate and traces.This is necessary for the manual checks by the engineers and also for automated checks through AOI, etc. Highly visible colors such as green, yellow, and white are easy to inspect, hence beneficial for prototype test and low-volume manufacturing runs.

Signal Integrity: The color of the solder mask makes a big difference in signal integrity, especially at high frequency. For example, blue masks boast of a very low dielectric constant and loss tangent, making them suitable for RF and microwave applications where signal integrity is crucial.

EMI/RFI Compliance: Black solder masks have an advantage in those areas of application where electromagnetic emission criteria are very stringent. The absorbency helps reduce unwanted emissions, thus being quite apt for sectors where this compliance is non-negotiable.

Aesthetic Goals: The solder mask color, apart from functional considerations, provides an aesthetic feel to the styling and appeal of the product. Colors like black and white give a sleek, high-tech look, while vibrant colors, such as red or purple, allow for brand alignment and differentiation.

Choosing the right solder mask color for your PCB strikes a balance among performance, visibility, and aesthetics. Green still generally stands as a good all-around choice, but it's helpful to understand what other colors can offer so that more strategic, informed decisions enhance both function and appearance. The choice will have to be guided by demands of the application based on requirements of inspection ease, signal transmission, emissions, and visual design.

At PCBCart, we value such considerations and have different solder mask options for various project needs. With our experience in PCB fabrication, we make sure boards not only meet but also excel in performance and design. Reach out to our team and learn how the perfect solder mask color can help bring out the best in your PCB project for optimum performance and aesthetics.

Request for High-quality PCB Assembly & Fabrication Quote

Helpful Resources

• Advanced PCB Assembly Services

• Standard PCB Fabrication Service

• PCB Prototype Service

• Layer Stackup Design Service