Many engineers, especially novice ask questions like "Where to find the cheapest PCB assembly service?" or "How to reduce my PCB assembly cost?" To tell the truth, there's never any cheapest PCB assembly service. For those who only strive for low prices while neglecting PCB assembly quality, their projects may very much likely be failed due to low quality circuit boards. Although PCB Assemblers constantly digging ways to reduce circuit boards assembly cost to attract more business and gain more profit, price varies from one assembler to another. We strongly recommend you find a PCB Assembler which offers the best balance between assembly quality, customer service and cost. The priority is to adjust your circuit design to reduce the assembly cost, than you should pick up the right PCB Assembler with the best overall service within your budget. Here, we'll discuss 6 effective ways to cut PCB assembly cost with the insurance of high quality.

Way#1: Locate a Reliable, Professional and "Low-cost" PCB Assembler.

Almost all PCB assembly services providers declare to provide cost-effective service, but not all of them offer what they claimed. Firstly, you should fully aware of your projects' requirements and budget, then conduct a research from head to toe on each assembler through Internet, magazines or trade show. A lot of time and efforts are required, but it'll be totally worthwhile. When research PCB Assemblers, make sure you cover the following aspects.

• Certificates

Certificates accurately ensure a PCB assembler's manufacturing capabilities and management regulations they stick to, necessary certifications include ISO9001, RoHS, UL etc. ISO9001 is a family of international quality management standards and guidelines aiming to promote global companies and organizations' capabilities to meet and exceed the needs and expectations of customers by efficiently and effectively improving the quality of their products and services. RoHS, short for Restrictions of Hazardous Substances, refers to a series of restrictive laws of application of 6 hazardous substances in the manufacturing of electronic and electrical equipment for environmental considerations. Applicable for PC boards and power supplies, UL listing service requires manufacturers to rigorously test their products by conforming to correct procedures in order to minimize product hassles.

• Equipment

Up-to-date equipment contributes to high efficiency and high quality of assembly. With the development and increasing popularity of SMT (Surface Mount Technology), SMT placement equipment is closely associated with components' high-precision placing and its high manufacturing speed.

• Component procurement

Based on our years' experience in PCB industry, we noticed too often money and time are lost in the PC boards manufacture stage because of the disjointed relationships between phases of the process. To save money and time, we recommend you cooperate with PCB Assemblers which offer components sourcing service. As thus, you can fully focus on project engineering and improving, and let the Assembler do what it's good at – purchase cheap but excellent components and assemble them onto your circuit boards. We'll discuss how to judge whether a PCB assembler features competitive components sourcing capability in the later part of this article.

Apart from those aspects, quotation rate, lead time, price, manufacturing capabilities, minimum order volume and others should be taken into consideration when selecting a reliable PCB assembler. Some of those aspects will be discussed in the following paragraphs.

It's worth mentioning that world electronic circuits are based on US dollar system, leading to few fluctuations on expenses between countries except labor cost that is distinctive from country to country. Therefore, PCB assemblers based in US and Europe have fewer advantages on price than those from populated developing countries China for example.

As selecting a perfect fit PCB assembler is such a complicated process, striving for only one or a couple of those aspects are just unilateral, you should consider them comprehensively.

Way#2: Optimize Schematic Design of Bare PCBs based on Low Cost Concern.

The first step before real manufacturing is to check whether your circuit can be normally implemented, which is called DFM check. A lot of PCB assemblers provide free DFM check service you can rely on to reduce the assembly cost.

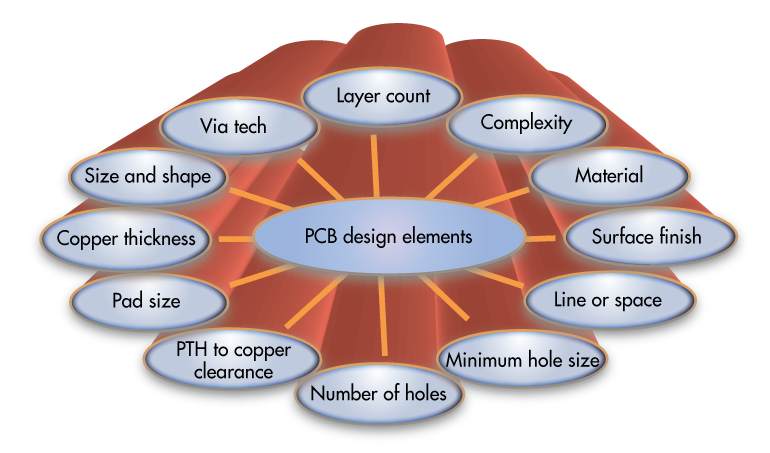

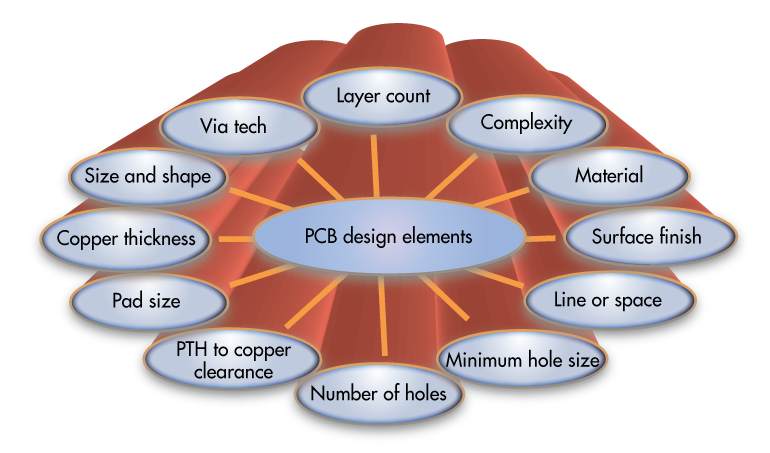

Factors influencing cost of bare PCBs are listed in the following figure:

To reduce the cost of your bare PCBs, measures can be done to each element:

• Layout Count

PCB cost increases with the adding of layer count, namely the more layers one circuit board has, the more expensive it'll be.

• Via Tech

Vias, including blind vias, buried vias or even microvias, play a key role in building interconnections on a circuit board. Generally speaking, the more vias, the more expensive and the smaller diameters of vias are, the more expensive PCBs will be. Therefore, you should carefully arrange the number of vias to reduce the cost of bare PCBs while guarantee the sufficient functions.

• Size & Shape

Circuit boards should be designed neatly and functionally. PCB's size should correspond to the requirement of pick and place equipment owned by your PCB assembler, it should be accurately designed to be capable of implementing all functions and accounting for moderate space. Panels are recommended when necessary. However, with the improvement of density and complexities of modern electronics, small PCBs can also be relatively complex. To be small doesn't directly lead to low cost.

Shape also affects price of PCBs. Basically, standard shapes such as square or rectangle lead to low price while special shapes lead to high price.

• Surface finish

By preventing pads from oxidizing, Surface finish helps ensure excellent solderability and electric performance. Different type of surface finishes (HASL, OSP, ENIG, ENEPIG etc.) has its advantages and disadvantages, chose the best fit surface finish type based on your products' requirement.

Actually, cost of bare PCBs results from comprehensive elements each of which possibly leads to slight fluctuation of final prices. These're only some tips based on our years' manufacturing and assembly experience, more tips can be expected from your own.

Way#3: Prepare an Effective and Complete BOM.

BOM, short for bill of materials, is a comprehensive list of raw materials, items, assemblies and sub-assemblies, components etc. for product manufacturing. You might think creating a BOM is much easier than making the Gerber file while we found more mistakes tend to be made in BOM then in Gerber files.

A complete BOM should include essential items for PCBA including Part number, Manufacturer name, Reference designator, Quantity, Description, Case/Package, SMT method, Top/Bottom, Points/Footprint, Comment/Note, BOM level, Comment/Note. Usually, PCB Assemblers have their in house BOM template and BOM creating guidelines, which you can fill in accordingly and speed up the quotation procedure.

It's highly recommended to add components replacement in your BOM. As electronics is developing super fast, components upgrade rapidly with old items eliminated. Though your PCB assembler will inform you about items that went out of production, time will be wasted to locate the replacement and production will be delayed accordingly. With the complete BOM and replacement provided, PCB assembler can quote in just one or two days and start the production with your confirmation. It's always good to look forward and be fully prepared for any kind of emergency.

Way#4: Make Components Sourcing Clear.

If you're with a company of small size, it's hard to control your budget and project schedule. Under this circumstance, rely on PCB assembler will make more sense. Record PCB assemblers are more likely to have friendly relationship with franchised component distributors due to their long-term cooperation. They can get your demanded components from those distributors at wholesale price, which is much lower than retail price. To evaluate a PCB assembler having genuine cooperation with franchised component distributor, you may ask for their purchase invoice from distributors.

Way#5: Adjust Order Volume and Lead Time.

Order volume is usually inversely proportional to the price of each commodity. In general, the more you order, the less expensive each circuit board assembly price will be (the same goes to PCB fabrication). Please take your company's situation into consideration, know your order volumes (high, medium or low), then select a PCB assembly manufacturer capable of providing service catering to your requirements.

In terms of lead time, the main problem lies in its calculation way. Different PCB assemblers have different lead time calculation ways. Make sure you know PCB Assemblers' lead time calculation: Where does starting time start from? The day you pay? The day you order? The day your components received? Well, the basic rule on lead time is that the longer your required lead time is, the lower price you'll get.

Way#6: Never Neglect Inspection or Test.

You must be wondering the relationship between cost reduction and inspection or test. In actual fact, inspection or test implementation drives to cost increase. However, under the theme of our mission explained at the beginning of this article, we aim to reduce cost without losing high quality of products. Inspection or test has been playing a crucial role in contributing to high quality of products by telling us about issues or mistakes in advance. Some PCB assemblers are capable of providing such service while others don't. It's more convenient and efficient to have products inspected or tested in their manufactured house. Under such conditions, PCB assembler usually provides a lower cost on inspection compared with those only dealing with inspection. Furthermore, your products don't need to suffer from being delivered everywhere.

If your PCB assembler provides inspection service for you at the end of production line, you should provide your test jig so that their test can be implemented according to your specification. Ordinary inspection methods range from visual inspection, AOI (automated optical inspection) to AXI (automated X-ray inspection).

For large volume order, it's necessary to carry out First Article Inspection on the first several products prior to real volume assembly. It leads issues such as component orientation and polarity to be exposed so that modification can be made in time. Time permitting, you can even ask your assembler to deliver sample products to you so that you can get it run in real circumstances.

There's one more rule, namely stick to one PCB assembler as your forever partner. If you are doing business with a PCB assembler for more than five years, then I suggest that you can depend on them continuously based on smooth cooperation, mutual credit and trust established through years. However, if you're having a tough time with your PCB assembler recently, or you're suffering from a cost crisis of your business, then it's time to make some changes. Rigorously conforming to the rules of thumb discussed in this article, you can adjust your decision and select your new PCB assembler again. And you'll surely cut some cost without sacrificing quality.

Article wrote by PCBCart's editor Dora Yang, originally posted on Electronic Design website.

PCBCart is dedicated to providing high-quality PCB manufacturing, assembly and prototyping services at an affordable cost.

PCBCart has been providing PCB fabrication, components sourcing and assembly services since 2005. We are capable of processing numerous advanced spec. You may find our detailed PCB assembly capabilities here. If you have circuit card assembly requirements, please contact us for more information. Or, you may click below button to request FREE and non-obligation PCBA quote!

Request for PCB Assembly Quote

Helpful Resources

• Full Turnkey PCB Assembly Service from PCBCart

• Components Sourcing Service from PCBCart

• How to Evaluate A PCB Manufacturer or A PCB Assembler

• Making the Best of China's Electronics Manufacturing Resources to Obtain Optimal Balance between Cost and Performance