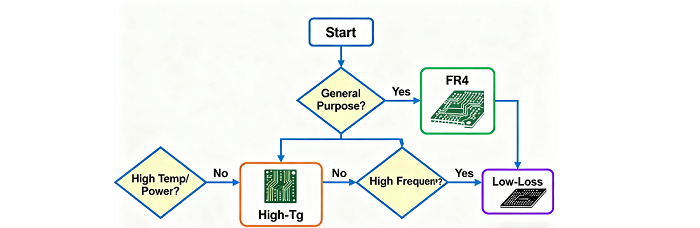

FR4 has always been the workhorse for Printed Circuit Board manufacturing, known for its cost-effectiveness, mechanical robustness, and compatibility with standard fabrication processes. However, as electronic devices go beyond higher frequencies, extreme operating temperatures, and tighter signal integrity requirements, these inherent limitations of standard FR4 have become increasingly pronounced. For an engineer or procurement team facing such challenges, knowledge of when to upgrade to High-Tg (glass transition temperature) or Low-Loss laminates becomes decisive, and PCBCart stands as your trusted partner in identifying and implementing the right material solutions.

Key Limitations of Standard FR4

Standard FR4, generally specified as having a Tg of 130–140°C and a dielectric constant [Dk] of ~4.4 at 1 MHz, is excellent for general-purpose applications but is lacking in four key areas:

Constraints of Thermal Stability: Below its Tg, FR4 maintains structural integrity, but when exposed to temperatures higher than 130°C - for example, automotive underhood systems, industrial controllers, or high-power electronics - the material softens, with resultant dimensional instability and greater risk of delamination. This becomes particularly troublesome in multi-layer PCBs or boards undergoing reflow soldering multiple times.

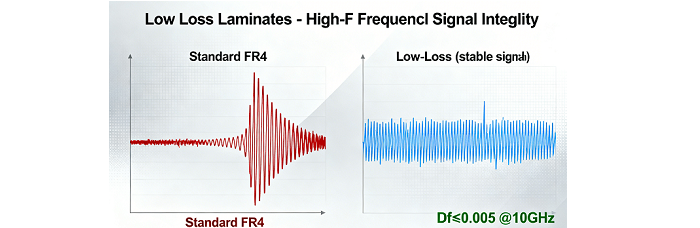

Poor High-Frequency Performance: As signal frequencies exceed 1 GHz, becoming prevalent in 5G, Wi-Fi 6/7, radar, and satellite communications, the high dielectric loss of standard FR4 (Df~0.02 at 1 GHz) causes excessive signal attenuation, crosstalk, and timing errors. Its Dk also shows higher variation with frequency, which impairs impedance control.

Limited High-Power Handling: In power electronics, such as inverters and motor drives, the low thermal conductivity of standard FR4 (~0.3 W/m·K) and susceptibility to thermal aging under continuous high-power loads cause reduced reliability and shorter service life.

Vulnerability in Harsh Environments: The absorption of humidity and chemicals from the environment diminishes the mechanical and electrical properties of standard FR4 over time, leading to early failure.

When to Upgrade to High-Tg Laminates

High-Tg laminates overcome the thermal limitation of standard FR4, with Tg ≥ 170°C - PCBCart offers options up to 200°C, making them indispensable in the following instances:

High-Temperature Operating Environments: If your PCB will be exposed to sustained temperatures above 130°C, such as automotive engine bays, aerospace electronics, or industrial furnaces, High-Tg materials resist softening and delamination. PCBCart's High-Tg FR4 variants, such as TG170, TG180, and TG200, maintain structural stability even with multiple reflow cycles at 260°C for more than 10 seconds, a perfect fit for lead-free soldering processes.

Multi-Layer and Thick PCBs: MLBs (8+ layers) or thick boards (≥4 mm) generate more heat during fabrication and operation. High-Tg laminates minimize warpage and improve interlayer adhesion, critical for maintaining signal path integrity in complex designs. PCBCart’s High-Tg solutions are optimized for blind/buried via structures and high-density interconnects (HDIs).

High-Power Electronics: Power converters, LED drivers, and industrial power supplies require materials that can dissipate heat and withstand thermal cycling. High-Tg laminates with enhanced thermal conductivity-up to 0.8 W/m·K in PCBCart's premium grades-reduce hotspots and extend PCB lifespan.

Reliability-critical applications: Medical devices, aerospace components, and military systems, require long-term stability. High-Tg laminates provide the best resistance to humidity, thermal aging, and mechanical stress; with IPC-4101/21 and MIL-PRF-28595 verification, these will also meet the strict quality control of PCBCart.

When to Choose Low-Loss Laminates

Low-Loss laminates (e.g., PTFE, PPO, or modified epoxy-based materials) are engineered for minimal dielectric loss (Df ≤ 0.005 at 10 GHz) and stable Dk, addressing standard FR4's high-frequency shortcomings. Upgrade to Low-Loss materials if:

Your Design Operates Above 1 GHz: 5G base stations, millimeter-wave radar, satellite transceivers, and high-speed data centers (100G+ Ethernet) require signal integrity at ultra-high frequencies. PCBCart’s Low-Loss laminates minimize the insertion loss and phase distortion with Dk=2.2 PTFE-based or modified epoxy Dk=3.4, among other options.

Impedance Control is Critical: RF amplifiers, antenna PCBs, and high-speed digital circuits (DDR5, PCIe 5.0) require impedance tolerances as tight as ±5% or better. Low-Loss materials support stable Dk across frequency and temperature, which enables precise impedance matching-supported by PCBCart's advanced dielectric modeling and PCB design services.

Weight and Size Reduction is a Priority: Aerospace and wearable devices benefit from Low-Loss laminates’ lower density (e.g., PTFE-based materials at 2.1 g/cm³ vs. FR4’s 1.9 g/cm³) and compatibility with thin-core designs, reducing overall system weight without compromising performance.

Low Signal Attenuation is Non-Negotiable: In long-distance signal paths, such as in backplane PCBs or communication cables, Low-Loss laminates reduce energy loss without requiring costly repeaters for the signal. PCBCart's Low-Loss portfolio includes both cost-effective modified epoxies and high-performance PTFE options to balance performance and budget.

PCBCart's Lamination Expertise: Your Upgrade Partner

Choosing the right laminate requires matching material properties with application requirements—and PCBCart simplifies the process by providing:

Material Selection: Our engineering team will analyze your design specifications-frequency, operating temperature range, power density, and cost targets-to recommend the best High-Tg or Low-Loss solution, from standard IPC-compliant grades to specialty materials, such as halogen-free, flame-retardant, or high-thermal-conductivity variants.

Full-Line Quality Control: All laminates go through strict testing, such as Dk/Df measurement, Tg verification, thermal cycling, and analysis of peel strength, at every PCBCart facility that complies with ISO 9001:2015 and IATF 16949 standards to meet or even surpass the industrial standards and your specific requirements.

Seamless Integration with Fabrication: PCBCart's fabrication process is optimized for High-Tg and Low-Loss materials, including precise controlled impedance routing, laser drilling for HDIs, and specialized lamination cycles to prevent delamination. We support prototype to high-volume production with fast lead times of as low as 24 hours for prototypes.

Cost-Effective Solutions: We balance performance and budget by offering tiered material options—e.g., modified epoxy Low-Loss laminates for mid-frequency applications (1–5 GHz) and PTFE for ultra-high-frequency (24+ GHz) designs—without compromising quality.

Conclusion

But standard FR4 remains a great choice for general-purpose PCBs. Issues like operating temperature, frequency, or reliability make the limitations of FR4 prohibitive. High-Tg laminates allow for thermal stability and durability in extreme environments, while Low-Loss materials provide the signal integrity required by next-gen electronics.

At PCBCart, we don't just supply laminates but deliver tailored material solutions with technical expertise, quality assurance, and customer-centric support. Be it a 5G PCB design, an automotive power module, or even a medical device, we are ready to support you in determining the right upgrade path. Contact PCBCart today to discuss your project requirements and tap into the full potential of your PCB design.

Get Instant Quote with Material Recommendation

Helpful resources:

• Factors Determining PCB Layers

• Halogen-Free PCB