The advancement of printed circuit boards from a simple, rigid substrate to an advanced, multi-faceted component reflects significant change in electronic design. As technology progresses, the need to downsize the electronic devices, increase their speeds, and boost their power has put into focus the importance of adequate thermal management. This has rendered the selection of an appropriate PCB substrate material between aluminum and copper core significant in the delivery of performance without compromising reliability. This article provides an in-depth overview of both the aluminum and copper core PCBs by looking into thermal performance, mechanical properties, cost, and manufacturing details to help you arrive at the correct decision for your next electronics project.

The Critical Role of Substrate Material

In PCB design, the substrate material significantly affects thermal management, durability, cost, and overall functionality. With ongoing miniaturization of devices, the efficiency of heat dissipation becomes a key issue. The leading positions in this respect are occupied by aluminum core and copper core PCBs, each boasting specific advantages that turn them into indispensable elements of top-performance applications. Understanding these differences will allow designers, engineers, and decision-makers to choose the best fit for their specific needs-be it powering LED lighting, designing automotive modules, or engineering consumer gadgets.

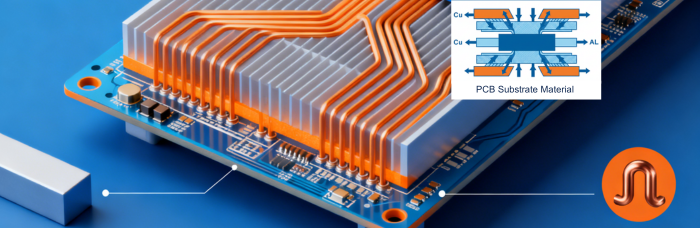

Copper Core PCBs: Excellence in Thermal Management

Copper core PCBs come with superior thermal performance and reliability, and are therefore applied in high-power and precision electronic devices. With a solid copper plate as a substrate, such PCBs have been designed to conduct heat away from sensitive components quickly for maintaining system stability and extending product life.

Key Features:

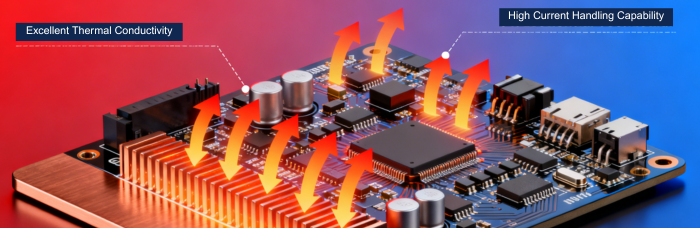

Excellent Thermal Conductivity: It has a thermal conductivity of about 400 W/mK, which is important for preventing sensitive electronics from being damaged by overheating.

Superior Mechanical Strength: Copper substrates offer significant rigidity, minimizing the chances of warping, flex, and physical damage even in extreme conditions.

High Current Handling Capability: Since copper has low electrical resistance, such PCBs can handle higher currents safely; hence, they can support high-powered loads and complex circuits.

Typical Applications:

Copper core PCBs are ideal for applications where consistent thermal performance and structural durability are mission-critical. Common uses of copper core PCBs are in LED lighting modules, automotive control systems, industrial power units, and high-current electronics.

Manufacturing Considerations:

Copper core PCB fabrication involves specialized fabrication techniques, including precision substrate cutting, controlled dielectric lamination, and high-temperature soldering. While these processes can raise costs, the resulting boards resist heat fatigue, extend component longevity, and provide superior electrical performance. In industries where failure is not an option, copper core PCBs are a requirement.

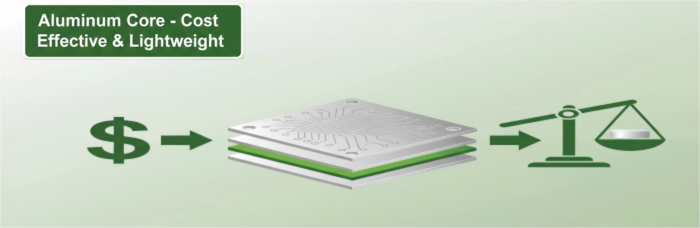

Aluminum Core PCBs: Balancing Cost with Performance

The MCPCB, or aluminum core PCB, is one such cost-effective alternative to realize lightweight thermal management while maintaining dependably high levels of electrical performance. It is, therefore, considered especially appealing in projects where budget constraints are a major consideration.

Key Features:

Good Thermal Conductivity: Aluminum core PCBs provide good heat dissipation of up to 200 W/mK, far better than the conventional FR4 boards. This has made them ideal for applications like LED lighting and power electronics.

Cost Efficiency: Aluminum's cost efficiency enables the production of high-performance, thermally stable boards within tight budget limits-a perfect option for mass-market products.

Lightweight and Flexible: the boards are lighter than copper counterparts, thus helping those designs where total weight needs to be minimized.

Best Applications:

The applications that involve the use of Aluminum core PCBs are found in an LED lamp, consumer power supplies, and automotive lighting where it uses moderate thermal control, and costs must remain low.

Manufacturing Benefits:

Manufacturing of the aluminum core PCBs is relatively simpler and cheaper; thus, projects that require speedy and scalable production are advantaged. They are also easy to machine and assemble, making them suitable for many practical applications.

Copper Core vs. Aluminum Core PCBs

Thermal Management: Copper core PCBs have the highest thermal conductivity, making them unparalleled in high-demand and heat-intensive applications.

Cost Efficiency: Aluminum core PCBs are considered an economical solution for projects in which budget sensitivity is critical but still offer effective thermal solutions for everyday applications.

Weight and Assembly: The lighter weight of aluminum makes handling and assembly easier, which helps when producing portable and lightweight devices.

Application-Specific Insights

The choice between an aluminum core and a copper core largely depends on the application context:

LED Lighting

Copper Core: Ideal for high-power LEDs applied to systems needing maximum heat dissipation, such as stage lighting and automotive LED applications.

Aluminum Core: Ideal for everyday LED bulbs, commercial lighting, and wherever cost-effective thermal management is needed.

Automotive & Industrial Power

Copper Core: Suitable for heavy current loads on engine control units and industrial drives.

Aluminum Core: Common in automotive light assemblies and industrial power supplies operating under moderate thermal demands.

Consumer Electronics

Copper Core: Utilized in laptops and gaming devices of the high-end range, where thermal regulation is vital.

Aluminum Core: Suitable for standard power adapters and small home electronics where budgetary concerns take precedence.

Harsh Environments

Copper Core: Used in extreme conditions requiring dependability, as seen in aerospace, medical imaging, and military applications.

Aluminum Core: Suitable for applications where moderate heat is the norm, along with less intense environmental demands.

Selection of substrate, whether it is an aluminum or copper core, shall be based on clear project goals, operating environments, power requirements, and budgetary considerations. As electronics continue to get smaller but more powerful, the need for optimal substrate selection will continue to increase and has prompted several valuable innovations in hybrid PCB designs with highly advanced thermal materials.

At PCBCart, we take pride in being more than just a supplier but your partner for innovative PCB solutions. The ability to provide tailored PCB manufacturing services to meet your project's technical and commercial demands is what enables your products to reach the peak of performance and reliability. We have extensive experience in fabricating both aluminum and copper core PCBs, using state-of-the-art technology and precision to deliver substrates that enhance your electronic designs. With PCBCart, you'll tap into a wealth of knowledge, quality assurance, and a commitment to excellence to help bring your concepts into fruition. Contact our professional team today for further inquiries or to request a quote and get your next project off on the right foot with PCBCart.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• A Comprehensive Introduction on Aluminum PCBs

• Metal Core PCB an Ideal Solution to Thermal Issues in PCB and PCBA

• Aluminum Backed PCBs: The Solution to High Power and Tight Tolerance Applications

• High-tech HDI PCB Fabrication Service from PCBCart

• PCB Materials