In the age of 5G, microwave communications, and high-speed digital systems, the performance of printed circuit boards (PCBs) is fundamentally determined by substrate selection. For high-speed applications—where operating frequencies exceed 1 GHz and data rates surpass 10 Gbps—two electromagnetic properties stand as non-negotiable decision drivers: dielectric constant (Dk) and dissipation factor (Df). These parameters directly govern signal propagation speed, energy loss, and impedance stability, making them the foundation of effective substrate selection. At PCBCart, we combine decades of high-speed PCB manufacturing expertise with rigorous material validation to guide engineers through matching substrates to their specific Dk/Df requirements. This article breaks down a systematic approach to selecting high-speed PCB substrates using Dk and Df as the core criteria.

Understanding Dk and Df: The Core of High-Speed Performance

To select the right substrate, it’s critical to first grasp how Dk and Df shape PCB behavior in high-speed scenarios—where even minor material variations can lead to catastrophic signal degradation.

Dielectric Constant (Dk): Speed, Impedance, and Miniaturization

Dk measures a material’s ability to store electrical energy in an electric field. Its impact on high-speed PCBs is threefold:

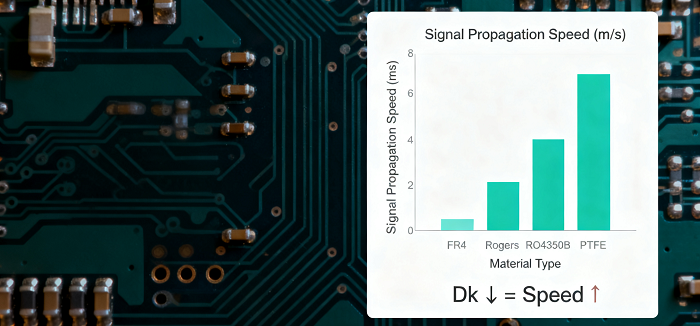

Signal Propagation Speed: Lower Dk values enable faster signal travel. A material with a Dk of 2.1 (e.g., PTFE) allows signals to propagate nearly twice as fast as standard FR4 (Dk = 4.3–4.7), a difference that is critical for timing-sensitive applications like 5G base stations or 25+ Gbps data center backplanes.

Impedance Control: High-speed designs rely on controlled impedance (typically 50 Ω for RF, 100 Ω for differential pairs). Dk directly dictates the trace width needed to achieve target impedance—higher Dk requires narrower traces, enabling miniaturization of RF components like antennas or resonators.

Stability: For frequencies above 5 GHz, Dk stability across temperature and frequency ranges is essential. Materials with erratic Dk values cause impedance fluctuations, leading to signal reflections and data errors. PCBCart prioritizes substrates with tightly controlled Dk tolerances (per IPC-TM-650 standards) to eliminate performance variability.

Dissipation Factor (Df): Minimizing Signal Loss

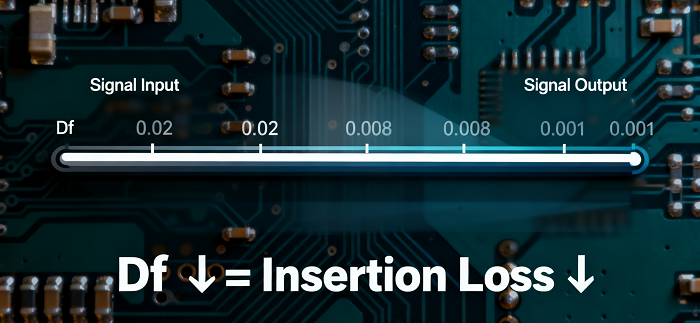

Df (or loss tangent) quantifies the amount of signal energy converted to heat as it passes through the substrate. In high-speed contexts:

Low Df is indispensable for long transmission lines or frequencies above 5 GHz. A Df of 0.001 (e.g., Rogers RO3003) results in negligible loss over a 10-inch trace at 10 GHz, while standard FR4 (Df = 0.02) degrades signals beyond usability in such scenarios.

Df directly influences insertion loss—the reduction in signal amplitude over distance. For critical applications like satellite communications or automotive radar, minimizing insertion loss is vital to ensuring reliable signal transmission across the entire PCB.

Surface finishes and copper foil quality complement Df: smoother very low-profile (VLP) copper and low-loss platings (OSP, immersion silver) reduce conductor losses, enhancing the performance of low-Df substrates.

Step 1: Align Dk/Df with Frequency and Signal Requirements

The first rule of substrate selection is matching Dk/Df profiles to your application’s frequency range and signal demands. As frequency increases, the sensitivity to Dk stability and Df magnitude intensifies—making targeted selection non-negotiable.

| Frequency Range | Recommended Dk Range | Recommended Df Range | Ideal Substrate Types | PCBCart Application Examples |

|---|---|---|---|---|

| < 1 GHz (Low-Speed High-Frequency) | 3.5 – 4.7 | 0.008 – 0.02 | Enhanced FR4 (e.g., Isola 370HR, Ventec VT-47) | Consumer electronics, basic IoT devices |

| 1 – 5 GHz (Mid-Range High-Speed) | 2.8 – 3.6 | 0.002 – 0.008 | Hydrocarbon-ceramic laminates (e.g., Rogers RO4350B), Panasonic Megtron 6 | 4G/LTE infrastructure, industrial sensors |

| > 5 GHz (Ultra-High-Speed/Microwave) | 2.1 – 3.0 | < 0.003 | PTFE-based laminates (e.g., Rogers RO3003, Taconic TLY-5) | 5G millimeter-wave systems, satellite communications, automotive radar |

For example, a 5G base station operating at 28 GHz requires a substrate with Dk < 3.0 and Df < 0.002 to mitigate signal loss over long traces—PCBCart typically recommends PTFE-based substrates for such use cases, as they deliver the ultra-low Dk/Df stability needed for millimeter-wave performance. Conversely, a 25 Gbps data center PCB (operating at 3 GHz) can balance performance and cost with a hydrocarbon-ceramic laminate like Rogers RO4350B (Dk = 3.55, Df = 0.0021).

Step 2: Balance Dk/Df with Thermal and Mechanical Stability

High-speed circuits generate significant heat—especially at frequencies above 10 GHz—so thermal and mechanical properties must complement Dk/Df to ensure long-term reliability. A substrate with ideal electrical properties but poor thermal resistance will fail in harsh environments like aerospace or automotive applications.

Thermal Stability

Glass Transition Temperature (Tg): Substrates must withstand soldering and operational heat. Lead-free (ROHS-compliant) designs require Tg ≥ 170°C, while high-reliability applications demand Tg ≥ 200°C (e.g., Rogers RO4000 series, Tg = 280°C).

Thermal Conductivity (k): Higher thermal conductivity (≥ 0.6 W/m·K) dissipates heat, preventing Dk/Df drift. PCBCart prioritizes substrates like Isola MT40 (k = 0.61 W/m·K) for high-power high-speed designs.

Coefficient of Thermal Expansion (CTE): Mismatched CTE between substrate and copper causes warpage or trace lifting. Materials with low Z-axis CTE (≤ 50 ppm/°C)—such as Rogers RO3006 (24 ppm/°C)—ensure mechanical stability during thermal cycling.

Mechanical Durability

For rigid PCBs, tensile modulus and flexural strength guarantee structural integrity during manufacturing and operation.

For flexible or rigid-flex high-speed PCBs, polyimide substrates (e.g., Ventec VT-901, Df = 0.012) offer a balance of low loss and flexibility, ideal for compact devices like wearables or aerospace components.

Dimensional stability (≤ 0.5 mm/m) and peel strength (≥ 1.1 N/mm) ensure substrates maintain performance under physical stress, a critical complement to Dk/Df stability.

At PCBCart, we validate substrates for a holistic set of properties—electrical, thermal, and mechanical—to ensure they perform reliably in your specific operating environment.

Step 3: Navigate Manufacturability and Cost Tradeoffs

Substrates with ultra-low Dk/Df (e.g., PTFE) often come with higher costs and specialized manufacturing requirements. Balancing performance with practicality is key, and PCBCart’s engineering team helps optimize this tradeoff.

Standard vs. Advanced Substrates

Enhanced FR4: A cost-effective choice for frequencies < 3 GHz. Materials like Isola 370HR (Dk = 4.17, Df = 0.0161) offer better Dk stability than standard FR4, making them suitable for mid-speed digital designs where budget is constrained.

Hydrocarbon-Ceramic Laminates: The sweet spot for most high-speed applications (1–10 GHz). Materials like Rogers RO4350B (Dk = 3.55, Df = 0.0021) and Isola MT77 (Dk = 3.0, Df = 0.0017) combine low Dk/Df with ease of manufacturing, reducing lead times and costs compared to PTFE.

PTFE-Based Substrates: The gold standard for frequencies > 10 GHz or critical applications (e.g., satellite communications). PTFE (Dk = 2.1, Df = 0.0003) delivers unmatched electrical performance but requires specialized processing (plasma etching, controlled drilling)—capabilities PCBCart’s facilities are fully equipped to handle.

PCBCart’s Cost-Optimization Approach

We work with engineers to identify “performance-adequate” Dk/Df values, avoiding over-engineering with ultra-premium substrates when enhanced FR4 or hydrocarbon-ceramic laminates meet requirements. For example, a 10 Gbps PCB operating at 4 GHz can achieve optimal performance with Panasonic Megtron 6 (Dk = 3.4, Df = 0.004) at a fraction of the cost of PTFE.

Step 4: Expert Collaborative Validation

PCBCart offers substrate selection services based on Dk and Df to ensure project success:

High-speed designs often demand custom solutions. PCBCart’s RF and high-speed PCB engineers collaborate closely with you to:

Analyze signal loss budgets and define precise Dk/Df thresholds.

Test prototype substrates to validate real-world performance (e.g., insertion loss, impedance stability).

Ensure compatibility with manufacturing processes (e.g., soldering, plating) to avoid yield issues.

Adhere to strict IPC standards (IPC-4101 for epoxy-based substrates, IPC-4103 for PTFE) to guarantee Dk/Df values match published specifications.

Conclusion: Partner with PCBCart for Dk/Df-Driven Substrate Success

Selecting high-speed PCB substrates based on Dk and Df is a blend of technical precision, application knowledge, and practicality. By aligning Dk/Df with frequency requirements, balancing thermal/mechanical properties, and optimizing for cost and manufacturability, you can unlock peak performance for your high-speed designs. At PCBCart, we simplify this process with deep material expertise, advanced selection tools, and end-to-end manufacturing support.

Whether you’re designing a 5G antenna, a high-speed backplane, or a microwave radar system, PCBCart helps you choose the right substrate to maximize signal integrity and minimize risk. Ready to eliminate guesswork from substrate selection? Contact PCBCart today to access our Dk/Df substrate database, consult with our engineering team, or request a custom quote. With PCBCart, you’re not just selecting a substrate—you’re partnering with a team committed to your design’s success.

Helpful Resources

• Guidelines for RF and Microwave PCB Design

• High-Frequency Materials: Rogers vs FR-4

• PCB Materials

• Solving Signal Integrity Issues in HDI PCBs