In today's electronic world, the protection and performance of printed circuit boards in harsh environmental conditions become an issue of crucial significance. Conformal coatings play a fundamental role in this respect, forming a thin layer of protection that shields the printed circuit board from environmental hazards including moisture, dust, heat, and chemical contaminants. These are vital for enhancing the life expectancy and reliability of electronic gadgets, especially for those applied under unfavorable conditions.

What Is Conformal Coating?

A conformal coating is a thin polymer film that "conforms" to the contours of a PCB and its components. This thin layer of protection provides a barrier to the operating environment, protecting sensitive circuitry. In contrast to potting, in which a solid mass totally encompasses the board, conformal coatings leave the board accessible for repairs and modifications. By providing thermal and electrical insulation, they preserve the operational characteristics of the circuit, thereby reducing failure rates and related costs.

Benefits of Conformal Coating

The main benefit from applying the conformal coating is the prolonged service life it gives to PCBs. Conformal coatings improve device reliability and reduce downtime by providing protection against environmental stressors. The longevity will then equate to reduced costs in frequent repairs or replacements. Additionally, these coatings have excellent thermal management features that assist in sustaining operating conditions that are optimal for components susceptible to temperature changes.

Types of Conformal Coatings

The proper selection of conformal coating is based on application-specific needs in terms of temperature, chemical, and mechanical exposure. Here are the five major types:

Acrylic-Based Coatings: Acrylic coatings are valued for their relatively low cost and easy application and thus are used in a lot of entry-level applications and hobby electronics. They offer very good resistance to moisture and UV but usually fail in high-temperature applications and exposure to solvents. These coatings can be easily repaired with non-aggressive solvents like isopropanol.

Silicone-Based Coatings: Silicone coatings would be perfect for the application involving very high thermal and mechanical stresses. They remain flexible even after curing; thus, providing very efficient protection against vibration and mechanical stress. These coatings support temperature up to about 200°C (400°F); however, they can act like a thermal barrier and reduce heat dissipation.

Polyurethane-Based Coatings: With a reputation for toughness, polyurethane coatings offer great resistance to chemicals and abrasions; hence, they are very suitable for industrial and harsh environments. But their removal is difficult, and the curing process generally requires controlled conditions; therefore, they are more suitable for large-scale productions rather than small batches.

Epoxy-Based Coatings: Epoxy coatings offer a hard, durable finish that effectively resists chemical splashes and limits moisture ingress. While robust protection is afforded, the rigidity of the material and difficulty in removal can be problematic should component replacement or board modification needs arise.

Parylene-Based Coatings: Applied using chemical vapor deposition, parylene coatings provide unmatched uniformity and dielectric strength. They offer superior protection in critical applications but are expensive and best reserved for high-value devices due to the cost and complexity involved.

Application Techniques

Application methods for conformal coatings depend on the volume of production, board complexity, and required uniformity:

Spraying: This method gives an even, uniform coverage and is suited for mass production. However, sensitive areas have to be masked with great care to avoid over-spray.

Brushing: Mainly utilized for small batches or repairs, skilled operators perform brushing to maintain uniform thickness and quality.

Dipping: Through immersion in coating material, dipping ensures that the PCB is well coated, although areas to be left uncoated must be masked out very carefully.

Vapor Deposition: Parylene coatings by vapor deposition involve gaseous coating deposition; hence, the coatings are laid down precisely and consistently without curing.

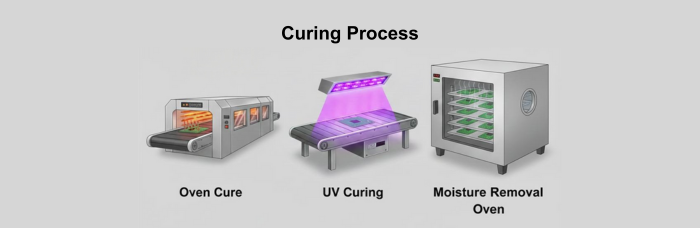

Curing Process

This coating needs to be cured once applied in order to achieve full protective potential.

Oven Cure: Most common for epoxy and polyurethane coatings, this involves heating the PCB to a certain temperature to set the coating.

UV Curing: This is used for UV curable coatings. The method involves exposing the board to ultraviolet light, which delivers quick curing, hence making it very viable for high-volume production.

Moisture Cure: Most appropriately applicable to silicone coatings, this process employs ambient moisture to cure the coating naturally, though it is a bit slower compared to other means.

Importance and Applications

The use of conformal coatings is especially crucial in industries like automotive, aerospace, consumer electronics, industrial controls, and marine electronics, where devices are often exposed to the worst environmental conditions. Conformal coating offers the PCBs additional resistance against moisture, chemical exposure, dust intrusion, and extreme temperatures, thus giving more reliability to the product and increasing its operating life. In automotive electronics, for example, conformal coatings make sure performance stability is maintained within changing conditions of temperatures, vibrations, and even dust. The protection in aerospace extends from humidity and changes in pressure at high altitudes down to temperature fluctuations, hence ensuring mission-critical component reliability.

Conformal coatings are used to protect printed circuit boards against moisture, dust, heat, and chemical contaminants. These types of coatings work by conforming to the surface of the board to provide thermal and electrical insulation, reducing failure rates while lengthening device lifetimes. To determine which type of coating-whether acrylic, silicone, polyurethane, epoxy, or parylene-is required, certain application-specific demands regarding temperature extremes, chemical exposure, and mechanical stress will come into play. Proper application and curing ensure that the coatings achieve their full potential of protection. The inclusion of conformal coatings is important for industries like automotive, aerospace, and consumer electronics, each looking to maintain reliable and robust electronic devices.

At PCBCart, by utilizing our profound knowledge in PCB manufacturing, we can offer top-level conformal coating services with solutions tailored to fit your project's demands. We are committed to quality, ensuring the PCBs we deliver are capable of withstanding adverse conditions with unparalleled reliability and performance. We're well aware of the intricacies involved in the selection and application of the right conformal coating and are always ready to support you in making the best choice for your applications. Whether your project requires mass production or customized prototypes, comprehensive support will be provided to ensure success. We invite you to request a quote today and experience the unmatched service and quality that PCBCart provides to help ensure the longevity and functionality of your electronic devices.

Get an Instant Quote for Cost-Effective PCB Assembly

Helpful Resources

• General Aspects You Should Know about Conformal Coating Applied on PCB

• How to Select PCB Coating for PCBs' Optimal Performance

• PCB Protection: Potting or Conformal Coating?

• Powerful Tips to Help PCBs and PCBAs to Better Work in Harsh Environment

• Advanced PCB Assembly Capabilities