Solder paste is commonly reduced to the simplistic role of an electronics glue in the complex environment of Printed Circuit Board Assembly (PCBA). The chemical engine of the whole manufacturing process is in fact the flux in that paste. Although it mostly fades when a board moves to the end of the line, the structural integrity, long-term reliability, and production yield of any assembly is determined by the selection of the flux.

To the industry professional, choosing a flux is not a buying exercise; it is an engineering decision which weighs chemical activity against post-assembly cleanliness. This guide explains the strategic reason why flux is picked so that your designs can go smoothly between the stencil and field.

The Functional Role: Why Flux is Essential

Soldering is essentially a metallurgical response. To create a strong bond, molten solder has to bond with a pure metallic surface. Nevertheless, copper pads and component leads form oxide coats nearly immediately in the presence of oxygen. These oxides serve as a shield so that the solder does not wet the surface.

Flux conducts three mission-related tasks:

Deoxidation: It reacts chemically and dissolves metal oxides to reveal the underlying raw metal at certain thermal limits.

Wetting Promotion: It also lowers the surface tension of the molten solder in order to facilitate flow and level bondage across the pads.

Atmospheric Shielding: It creates a protective layer when subjecting the assembly to high temperatures in the reflow oven, it prevents the re-formation of oxides.

The chemistry of the flux should be active enough to clean the surfaces but stable enough not to evaporate before the alloy reaches its liquidus. It is this subtlety that makes the difference between a good solder paste and a poor one.

Key Flux Types and Applications

The majority of newly used PCBA applications are divided into three chemical groups. The main factors that persuade you to choose one option over another are your reliability needs and the cleaning capabilities of your facility.

Rosin-Based Flux (R, RMA, RA)

The classical option in electronics, based on natural pine resin (colophony). Rosin is a compound that is non-conductive and non-corrosive at room temperature and thus is unique to electronics. It activates only when subjected to heat.

R (Rosin): This is minimum activity flux. It is applied to clean, very solderable surfaces such as gold plated pads or freshly cleaned copper.

RMA (Mildly Activated): The military, medical, and aerospace high-reliability project standard. It provides fair cleaning ability but leaves quite safe, non-conductive residues.

RA (Activated): Extremely aggressive on oxidized surfaces or older parts. Nevertheless, it deposits conductive residues that should be eliminated using special solvent removers to avoid the occurrence of field failures in the long-term.

No-Clean (NC) Flux

Built to cater to the high-volume consumer market, no-clean fluxes have small, non-conductive residues. They are made to be permanent on the PCB without being corrosive.

Benefits: It saves time, equipment and water used in a wet clean, making the production line much faster.

Strategic Consideration: The residue may be tacky, although intended to remain on the board. This can cause Automated Test Equipment (ATE) pins to be shorted or conformal coatings to be compromised. Even no-clean boards are frequently washed in high-reliability industries to achieve the best surface insulation resistance.

Water-Soluble (WS) Flux

These fluxes are organic acids (OA), and are very active and give excellent soldering performance on difficult metals such as stainless steel or highly tarnished copper.

The Mandate: The residue is very conductive and corrosive. This should be completely washed off with high-pressure, deionized water systems immediately after reflow.

Result: Since the cleaning process is so aggressive, it offers the highest ionic cleanliness, which are frequently needed in application at high-frequency or high-voltage levels where even a smearing of residue may result in signal short.

Precision Selection: Interpretation of IPC J-STD-004

In order to evade marketing jargon, practitioners use the IPC J-STD-004 classification system. A four character code (e.g., ROL0) gives a clear map of the chemical properties of the flux:

First Two Letters (Base): RO (Rosin), OR (Organic), RE (Resin), IN (Inorganic).

Third Letter (Activity): L (Low, <0.5% halides), M (Medium, 0.5%-2.0%), H (High, >2.0%).

Final Number (Halides): 0 (Halide-free), 1 (Contains halides).

To achieve high-reliability, no-clean assemblies, ROL0 type is usually the gold standard, with a low-activity content and zero content of the halide.

Technical Factors Affecting Choice

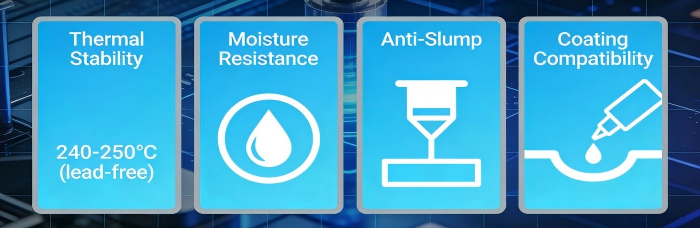

Thermal Stability (Lead-Free vs. Leaded)

Switching industries to Lead-Free alloys (e.g., SAC305) has raised reflow temperatures to the 240degC-250degC range. Your flux should be stable to heat to this higher temperature during this long heat retention cycle. When a flux burns out early, it will produce poor wetting and grapping defects.

Environmental Sensitivity and Slump

Flux is hygroscopic (moisture-absorbing). Flux may take up air moisture in wet manufacturing conditions and results in splattering or solder balls on reflow. Moreover, the flux has to be tacky enough to keep the components in position and avoid "slump"- the propensity of the paste to flow and form bridges between small-pitch pads.

Post-Reflow Coating Requirements

When conformal coating is needed to protect against moisture on your application, the surface should not have residues of flux to be able to be properly adhered to. Where such cases are encountered, although with a no-clean flux, it can be recommended to follow this with a separate cleaning step in order to avoid delamination of the coating.

The choice of solder paste flux is an essential engineering choice that seals the divide between design and longevity. Even though you are more concerned about No-Clean convenience or the cleaning aggressiveness of Water-Soluble flux, it is crucial to know how chemistry and process interact to achieve high-yield manufacturing.

At PCBCart, we combine over 20 years of manufacturing expertise with rigorous quality control to ensure your material selection aligns perfectly with your performance goals. Our engineers provide detailed DFM (Design for Manufacturing) reviews and specialized solder paste consultations, helping you navigate complex IPC standards and lead-free requirements with confidence.

Request for High-quality PCB Assembly & Fabrication Quote Now