We are living in a time when small and powerful electronicsre everywhere. Surface-mount technology is very important for making printed circuit boards. There are types of surface-mount devices but the 0201 SMD package is really special. It helps make small and powerful electronic products.

The 0201 SMD package is a tiny component that is used a lot. It is very important for making devices like smartphones and medical wearables that're slim and powerful. The 0201 SMD package is used to meet the demand, for these kinds of devices. Let us take a look, at the 0201 SMD package. We will go over the details of the 0201 SMD package, what it can do and what makes it useful. The 0201 SMD package has its set of specifications. The advantages of the 0201 SMD package are important to know. We also need to think about where the 0201 SMD package can be used. When we want to use the 0201 SMD package there are some things to consider for successful integration of the 0201 SMD package.

Core Specifications: Dimensions and Coding

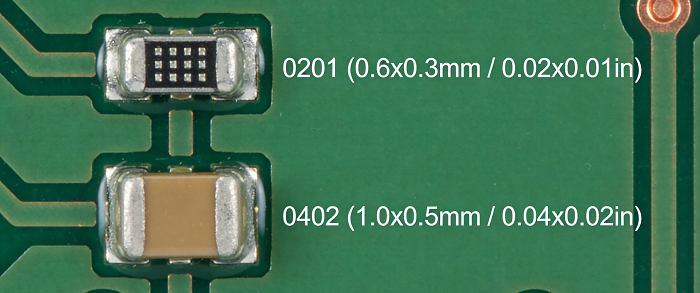

The "0201" designation is really about the size of the package. This size is measured in two ways: inches and millimeters. The "0201" code in inches means the package is 0.02 inches long and 0.01 inches wide. If we look at the "0201" package, in millimeters it is 0.6 mm long and 0.3 mm wide. The "0201" package size is small. These measurements help us understand how small the "0201" package really is. The 0201 SMD is really small compared to things like the 0402 package that is 1.0 mm by 0.5 mm. This means designers can fit a lot 0201 SMD components into the same space, on the PCB. The 0201 SMD components are very tiny.

It’s important to clarify potential confusion between imperial and metric coding: imperial codes (e.g., 0201, 0402) are based on hundredths of an inch, while metric codes (sometimes misinterpreted) reference millimeters directly. For the 0201 package, the imperial code is the industry standard designation, and its compact dimensions—often paired with a thickness of around 0.3 mm—make it one of the smallest standardized SMD packages in mass production.

Key Advantages and Applications

The 0201 SMD package is really good, at helping to make the most of the space on a circuit board. This is important because it does not affect how well the circuit board works. Here are the main advantages of the 0201 SMD package:

· High Component Density: The 0201 SMDs are really good at this. They let designers put resistors and capacitors and other components like these on a single PCB. This is great for devices where size really matters. The 0201 SMDs help make these devices smaller. They support functions in a smaller space. This means devices like these can do things even though they are small. The 0201 SMDs are very useful, for making devices with functions that do not take up a lot of space.

· Shorter Signal Paths: They let us put components close to the IC chips. This helps a lot because it reduces the inductance and capacitance that we do not want. This is very important for circuits that use frequencies, like the RF modules and antenna circuits, where we need to make sure the signal stays strong and clear.

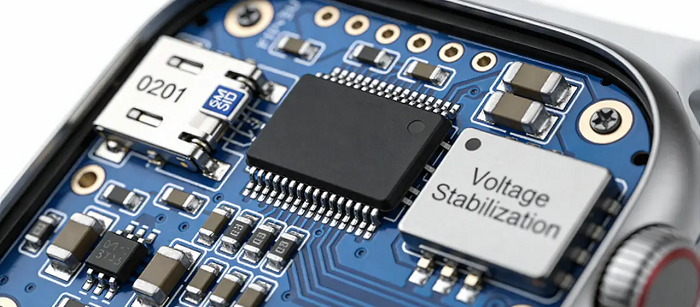

· Lightweight and Slim Form Factor: This means that things like smartwatches and fitness trackers can be thinner and lighter. It is also good for smartphones, tablets and medical devices that people carry with them. These things need to be small and light so they are easy to use. The small size of the package is important, for making these things better. For example smartwatches and fitness trackers are types of wearables that benefit from the package being small and lightweight.

The good things about the 0201 SMD package make it really necessary for things, like:

· Consumer electronics (smartphones, tablets, wireless earbuds)

· Wearable technology (fitness trackers, smartwatches)

· IoT devices and high-density embedded systems

· Medical electronics (portable diagnostic tools, wearable health monitors)

· RF modules and high-frequency communication equipment

Critical Considerations for Assembly

The 0201 SMD package is really useful, for designing things. It is very small. This small size of the 0201 SMD package makes it hard to work with when putting things on a printed circuit board. You need to be very careful and have tools. The 0201 SMD package also needs a lot of control over how it's put together.

· Precision Placement: The package needs to be put in the right place. This is very important because the component has to line up with the PCB pads. The machines that pick up and put down the components have to be very good at doing this job. They have to pick up the components and put them down in the place every time so that the component does not get put down in the wrong place. This is especially important, for the 0201 components because they are so small.

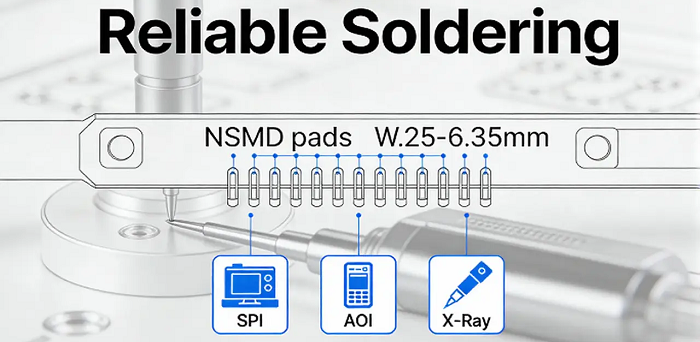

· Solder Pad and Stencil Design: Non-Solder Mask Defined (NSMD) pads are preferred for 0201 SMDs, as they expose more copper to enhance solder joint reliability. Stencils require precise thickness and tapered sidewalls to ensure consistent solder paste application, paired with appropriate flux-compatible solder paste for optimal wetting.

· Reflow and Inspection: The temperature in reflow ovens needs to be just right. It can damage the components or make them stand on end which is called "tombstoning". This is when the components tilt during the soldering process. After the components are put together we need to check them. We use tools like SPI, which is Solder Paste Inspection, AOI, which is Automated Optical Inspection and X-Ray to find problems that we cannot see with our eyes. We have to use these tools because some defectsre not visible when we do manual checks, on the Reflow and Inspection process.

· Component Handling: These tiny 0201 SMDs are really easy to lose or damage when you are trying to feed them and put them in place. That is why you have to be very careful with them. You need to think about how you're going to manage these 0201 SMDs and plan your inventory just right. If you do not do this your project will probably be delayed. You have to be careful, with these 0201 SMDs to get everything done on time.

Partner with PCBCart for Seamless 0201 SMD Integration

Successfully integrating 0201 SMD packages requires a partner with deep expertise in high-precision PCB manufacturing and SMT assembly—capabilities that PCBCart brings to every project. As a trusted provider of PCB production and SMD assembly services, we are equipped to address the unique challenges of ultra-small component integration, ensuring reliability and consistency for your high-density designs.

Our tailored support for 0201 SMD projects includes:

· Precision PCB Manufacturing: We produce PCBs with tight dimensional tolerances and optimized pad designs (including NSMD pads) to match the exact requirements of 0201 SMD components, ensuring compatibility and mechanical stability.

· Expert SMT Assembly: Our SMT lines are configured for ultra-small component handling, with precision placement systems and strict process control for solder paste application and reflow profiling. This minimizes common risks like tombstoning, solder bridging, and misalignment—critical for 0201’s miniature form factor.

· Advanced Quality Inspection: We utilize SPI, AOI, and X-Ray inspection technologies to verify solder paste quality, component placement accuracy, and solder joint integrity, ensuring every assembly meets rigorous quality standards.

· Design for Manufacturability (DFM) Support: Our engineering team provides pre-production DFM reviews to assess your PCB layout, identify potential assembly challenges, and recommend optimizations to streamline 0201 SMD integration—saving time and reducing rework risks.

Whether you’re developing a compact wearable, a high-frequency IoT module, or a precision medical device, PCBCart’s PCB production and SMT assembly services are designed to unlock the full potential of the 0201 SMD package. Partner with us to translate your high-density, miniaturized design goals into tangible products—backed by expertise, quality, and a focus on your project’s unique needs.

Get an Instant Quote for High-Quality FR-4 PCB Fabrication

Helpful Resources

• Flexible PCB

• First Article

• SMT Assembly Procedure & Development Trend

• Electrical Test