In terms of surface mount device packages, any permeable packaging material, plastic or metal, absorbs moisture from the air. When the package is exposed to sudden high temperature of solder reflow during PCB assembly process, moisture will expand rapidly and damage the component. Sometimes the damage is visible such as cracks and/or delamination in the package. Other times, it's internal and not visible. Either circumstance has seen product's susceptibility to failures with its quality and reliability threatened. MSDs, an acronym of Moisture Sensitive Devices, can be ICs, LEDs and even connectors. They demand particular storage and handling methods to end up guaranteeing the improvement of yield and reliability.

Terms and Definitions

Along with the introduction and discussion on how to store and handle moisture sensitive devices, it's also important to go through the technical terms below accompanying MSDs to accurately understand the content of the remaining article.

• Bar code label. This refers to the manufacturer's label that contains information in a code composed by parallel bars with different widths and spaces. The information describing the product includes part number, quantity, lot information, supplier identification and moisture sensitive level (MSL).

• Carrier. Carrier is actually a container that holds components such as a tray, tube, or tape and reel.

• Desiccant. A type of material capable of absorbing moisture and is applied to maintain ambient RH (relative humidity) within a relatively low range.

• Floor life. It indicates the longest time of MSDs exposed to factory environment (≤30°C/60%) before solder reflow with moisture barrier bag opened.

• Manufacturer's Exposure Time (MET). Manufacturer stipulates the longest exposure time from baking completion to sealing package, which accounts for MET. This term also applies to the MSD's exposure time from the opening of vacuum package to resealing.

• Moisture Barrier Bag (MBB). It is used to pack moisture sensitive devices and stop water vapor from permeating into the bag.

• Shelf life. It is a length of time during which MSDs can be stored in sealed MBBs.

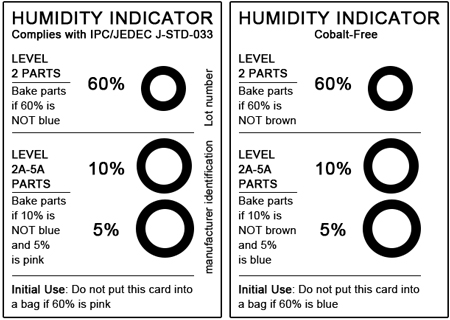

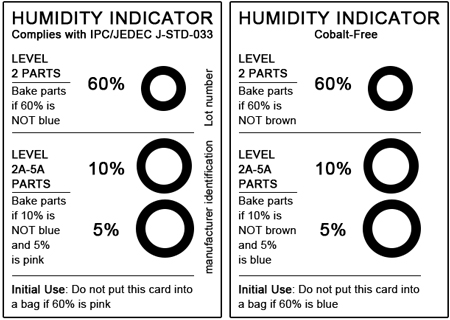

• Humidity Indicator Card (HIC). Made from chemical products, HIC is a card applied to measure RH sensitivity degree. When the indicated RH is exceeded, corresponding dot will show a color change from blue to pink. Together with desiccant, HIC is placed inside moisture barrier bag to determine the humidity degree of MSDs inside.

Procedure

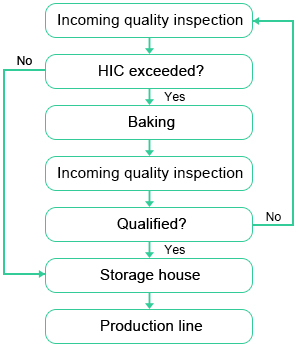

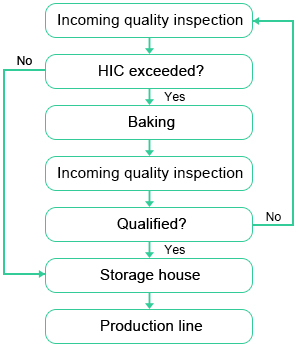

Prior to their authentic applications in PCB assembly, solder reflow specifically, MSDs have to go over complicated and professional procedure for inspection and drying such that humidity failures will be effectively avoided.

Step one: carry out incoming quality inspection before MBBs' opening. That is because MBBs have to be checked from appearance to see whether they have suffered from issues, while MSL, floor life and bag seal date of MSDs should be verified to decide correct handling solutions.

Step two: open MBBs and check the HICs. If the indicated RH on HIC is exceeded, baking has to be implemented with time and temperature conforming to MSLs and package type. When components' shelf lives have been exceeded, they should be rejected and returned to manufacturers or distributors.

Step three: MSDs through baking have to be inspected again to ensure their humidity effect. If they still suffer from a high degree of humidity, a second baking has to be considered.

Incoming Quality Inspection

As soon as MBBs containing MSDs are received, appearance inspection should be carried out first in order to verify there are no holes, gouges, tears, punctures or openings. All these defects will possibly lead components or inner layers of MBBs exposed. If holes are unfortunately found on MBBs with inner components exposed and HIC showcases an exceeded data, baking should be undertaken on parts before their genuine applications.

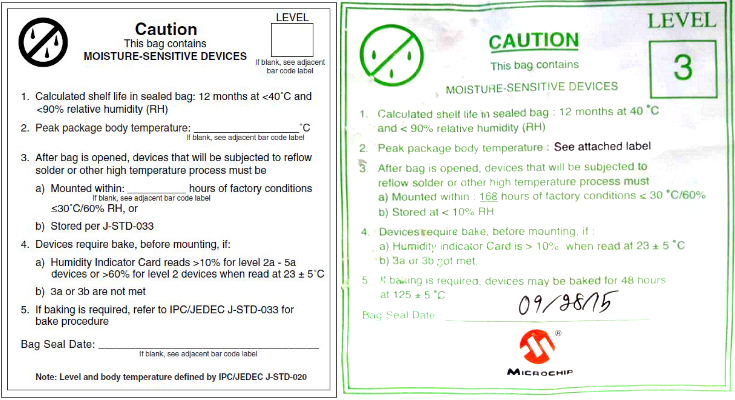

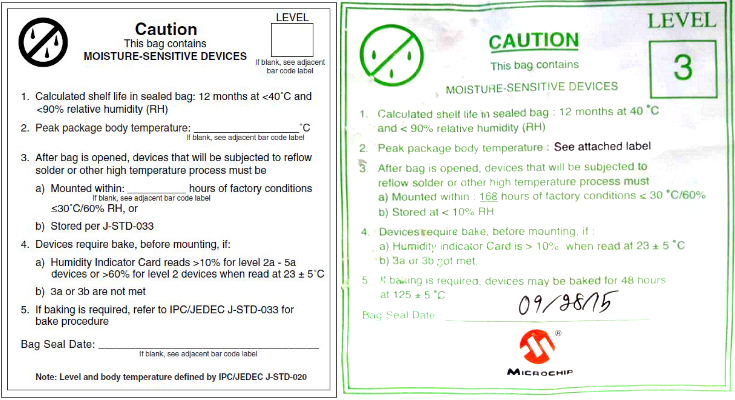

Then bag seal date printed on caution or bar code label should be checked in order to simply figure out the remaining shelf life of the MSDs packed inside MBBs. The minimum shelf life of a standard MSD is at least 12 months from its seal date.

MSDs differ from each other based on different Moisture Sensitive Levels (MSLs) ranging from Level 1 through Level 6. The following table indicates floor life of MSDs corresponding to their MSLs.

|

MSL

|

Floor life at factory ambient (≤30°C/60% RH)

|

|

1

|

Unlimited at ≤30°C/85% RH

|

|

2

|

1 year

|

|

2a

|

4 weeks

|

|

3

|

168 hours

|

|

4

|

72 hours

|

|

5

|

48 hours

|

|

5a

|

24 hours

|

|

6

|

Mandatory bake before use. After bake, must be reflowed within the time limit specified on the label.

|

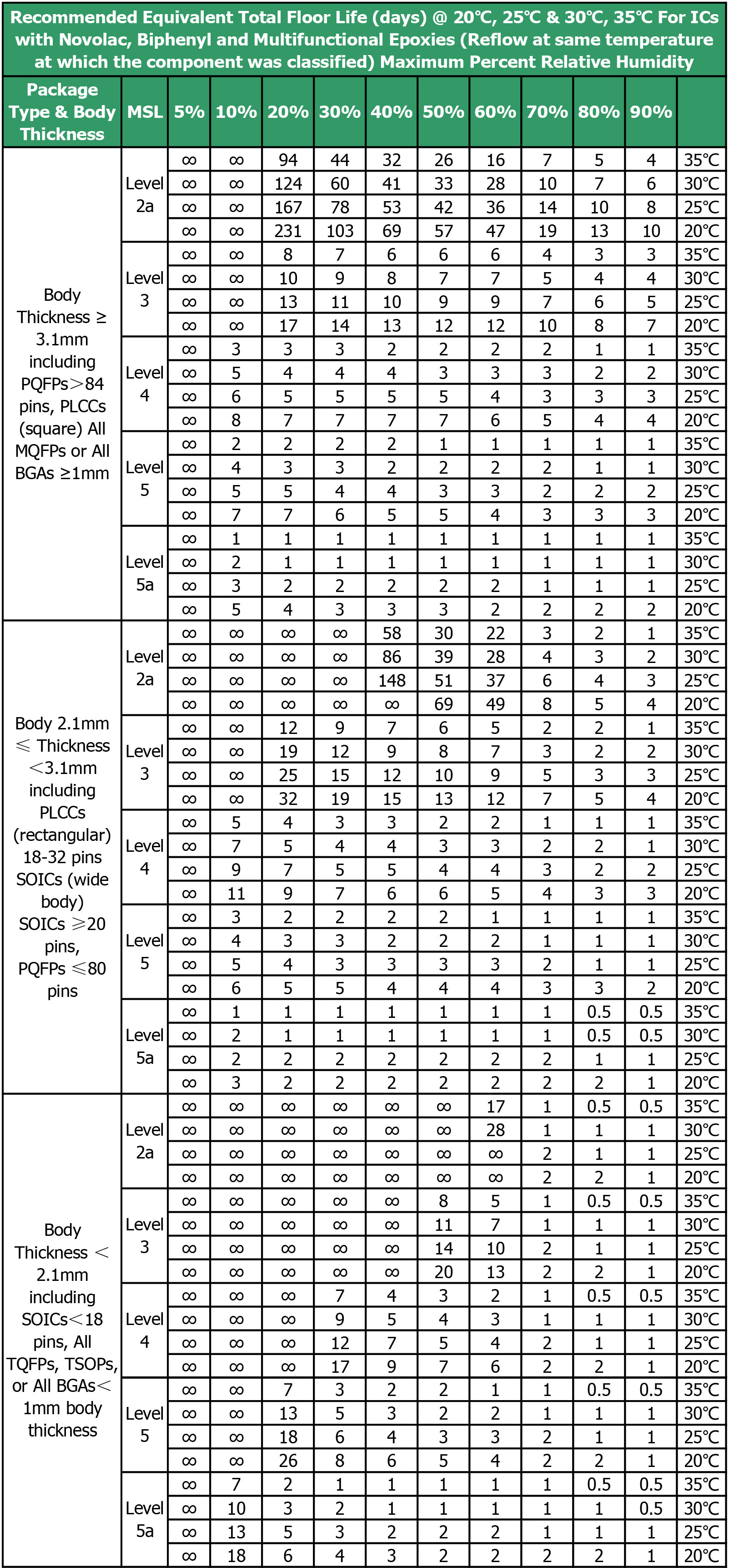

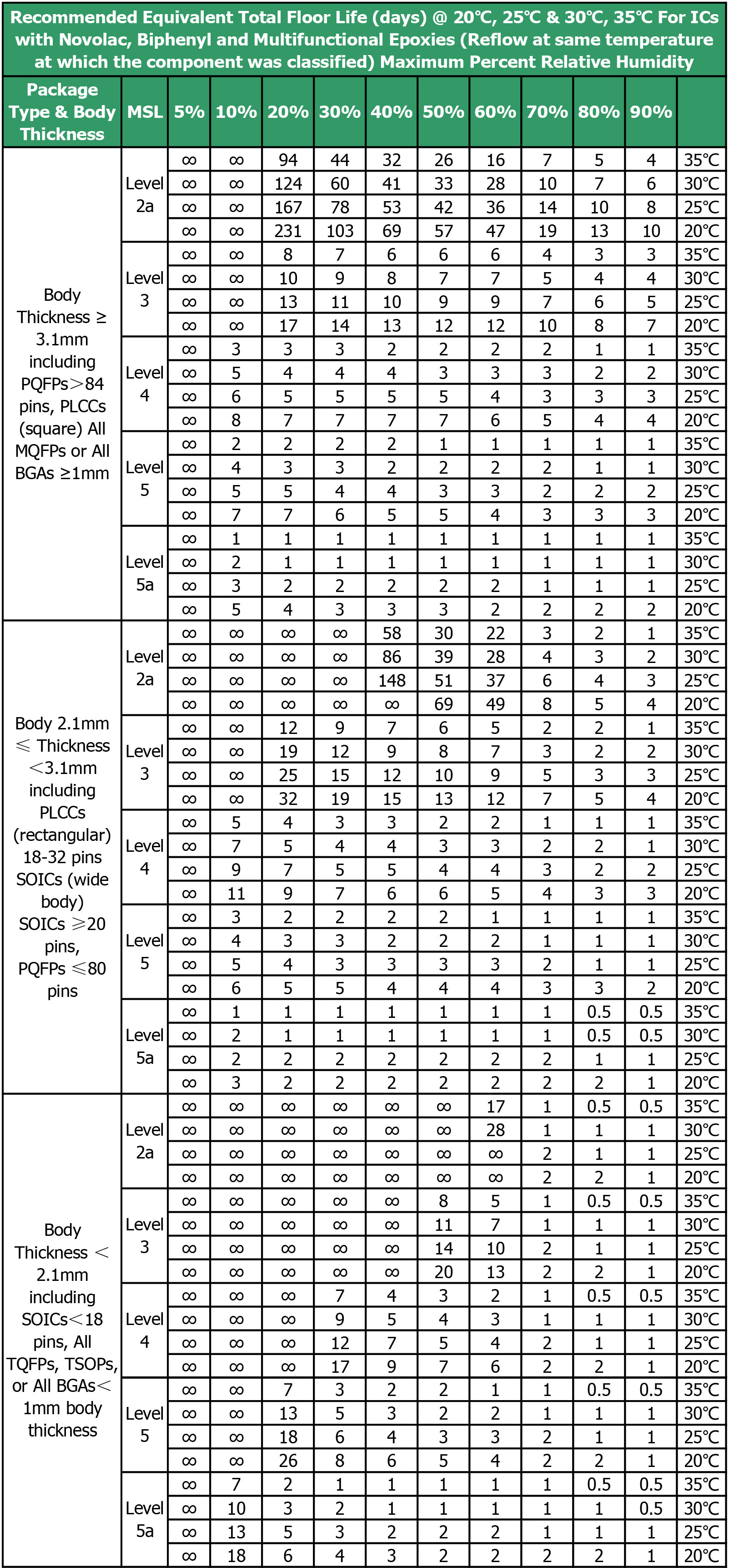

Therefore, components' exposure time has to be rigorously controlled according to the demands of MSLs and records carefully kept of every production run to ensure the total floor life hasn't been used up. Nonetheless, the regulation described in the table doesn't work when the factory humidity or temperature exceeds the default ambient ≤30°C/60% RH. The following table, excerpted from IPC/JEDEC J-STD-033B.1, provides floor life to MSDs with different package types, at different MSLs, temperatures and RH.

∞ represents indefinite exposure time allowed at conditions specified.

Reflow

The opening of MBB indicates the beginning of floor life countdown. Once an MBB has been opened, all the contained SMD packages have to be ended up with being used for solder reflow prior to stated floor life.

Reflow temperature has to be carefully set and it mustn't exceed the rated temperature value stated on the Caution label of SMD packages. Some SMD packages have to go through more than one solder reflow. No matter how many times of solder reflows a component needs to embrace, care must be taken to ensure that no moisture sensitive SMD packages have surpassed their floor life before the last run. Any component found to be over floor life has to go over baking again before the next reflow takes off.

Generally speaking, a component can withstand solder reflows for three times at most. Therefore, when more than three reflows have to be carried out on MSDs in the manufacturing, sufficient research and inquiries have to be completed prior to reflow.

Storage Solutions for MSDs: Dry Cabinet and Dry Pack.

• Dry cabinet

Dry cabinet can be applied to dry both components and package materials. In order to achieve acceptable drying effect, RH inside dry cabinet should be maintained at the level of no more than 5% while temperature no more than 30°C. Components can be either directly exposed inside dry cabinet or sealed in MBBs. Labels should be kept on the package of components in order to track down the accurate exposure time to further figure out the remaining floor life and shelf life.

• Dry pack

Components can be stored the way of dry pack. First, components are placed inside an MBB. Second, put suitable amount of desiccant and a HIC into MBB. Note that the HIC mustn't be placed directly on top of desiccant since this will stop HIC accurately reading the correct humidity data. Third, press the bag so as to drive the air out of the bag. A vacuum can be used when necessary. Fourth, seal the MBB with a heat sealer. The sealing has to be carried out within an acceptable degree. Too much sealing will possibly lead components to be torn while insufficient sealing can't work as a dry pack. Finally, place a label outside the dry pack containing information such as part number, quantity, MSL, exposure time, floor time etc. A well-packed MBB should be remained in ambient conditions ≤40°C/90% RH.

Both storage solutions have their own advantages and disadvantages that are summarized into the following table.

|

Terms

|

Dry Cabinet

|

Dry Pack

|

|

Cost

|

Depending on type, size, make and model;

|

Cheapest;

|

|

Types

|

Desiccating and dry gas;

|

Sealed MBB with desiccant and HIC;

|

|

Size

|

Relatively large (single or multi chamber);

|

Small size compatible to component package size;

|

|

Installation

|

Requiring power or gas hook-up;

|

Bag heat sealer;

|

|

Typical usage

|

Temporary storage on manufacturing floor or short term inventory;

Applicable for short duration rule;

|

Long term or short term inventory storage

Applicable for short duration time;

|

|

Maintenance

|

Manufacturer's specifications or monthly;

|

Minimal: ensure prosper seal;

|

|

Advantages

|

Capable of storing components without an MBB;

|

Well-controlled environment for MSD;

|

|

Disadvantages

|

Requiring added maintenance;

|

Manual process;

|

As a full turnkey PCB Assembly service provider serving worldwide clients for over 20 years, PCBCart has built strong cooperative relationship with authorized component distributors including Digi-Key, Mouser Electronics, Arrow Electronics, etc. To free you from storage issues due to lack of space and facilities, we offer free components storage as a value-added service. You are welcome to store your remaining parts at our office without cost. Your components will be taken good care of, and can be applied to any of your future assembly project with PCBCart.

Except for this, we also have free DFMA check, first article inspection, custom testing and many other options. Feel free to submit quote request for your next PCB Assembly project and see how much you can save to get quality guaranteed assembled circuit boards from PCBCart.

Request for Free PCB Assembly Quotation

Get more info about PCBCart here:

• PCBCart's Advantages over other PCB Manufacturers - Why should you chose PCBCart?

• Standard PCB Fabrication Service with Multiple value-added Options

• Quickturn PCB Prototyping Service

• Aluminum PCB Fabrication Service

• Flexible PCB Fabrication Service

• Flex-rigid PCB Fabrication Service

• High Frequency PCB Fabrication Service

• Thick Copper PCB Fabrication Service

• High -Tg PCB Fabrication Service

• Halogen-Free PCB Fabrication Service