We received many messages from electronics Makers asking for PCB making tips. In order to help them successfully etch their circuit board at home, we present this step-by-step home PCB etching tutorial.

PCB etching is a big topic in electronics Maker community. It's something every electronics enthusiast will set hand to when he or she steps into electronics DIY world. Though it looks like a very simple procedure, it does require determination and perseverance as the procedure generates strong-smelling hazardous chemicals.

Generally speaking, PCB etching procedure contains four main steps, namely PCB Design, Exposure to light, Imaging and PCB Etching. Primary material and tools for etching printed circuit boards includes etchant (we recommend green etchant, it's riendly to our environment), developer, two plastic plates (a big one and a small one), a sprinkling can, a brush, a PMMA (5mm), a light-sensitive plate and some protection tools including gloves, protection glasses and an apron.

Step 1: Design a PCB.

There're any PCB design programs available on the market, and we have an article about PCB Design Software Survey. Hopefully you can find the program that best fits your requirements. Once the design process is done, you can get it printed through a printer.

Then you can use the PMMA to make light-sensitive plate and the PCB design graphic closely dovetailed. It is very important as the bad dovetailing leads to the bad imaging effect.

Step 2: Exposure to light.

Given you may create this PCB at home and it's inconvenient to get a dedicated UV exposure lamp, we recommend try an ordinary table lamp. Please keep the distance between light-sensitive plate and table lamp within 5 to 10 cm, and keep it under the lamp for 9 to 12 minutes. Otherwise, the etching will probably be failed.

Step 3: Imaging

Make sure you wear gloves when implementing this step as developer is harmful for human skin. Use the sprinkling can to spray developer onto your circuit board. The developer needs some time for reaction, you have to wait for about 30 seconds before brushing it from the board. It's important to control your strength when brushing, too much strength will possibly cut the line on the board. Brushing is completed once all circuits are imaged clearly. Please do not take it for granted that the more developer you spray, the clearer the image will be. As they say, a little wind kindles, much puts out the fire. If too much developer is used, the circuits may very much be totally cleaned.

Step 4: PCB etching

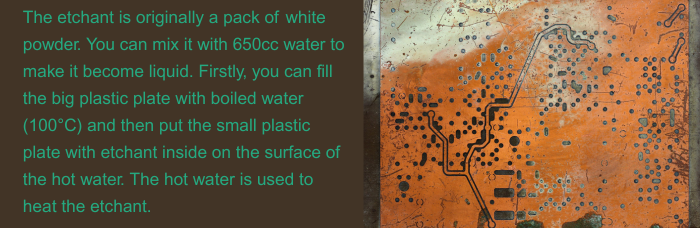

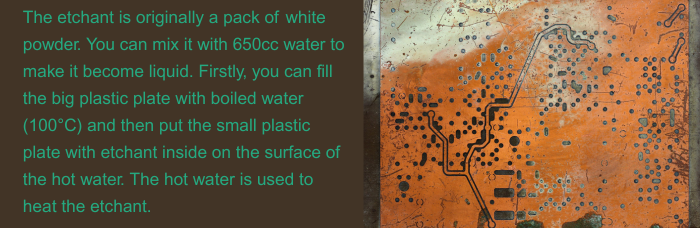

The etchant is originally a pack of white powder. You can mix it with 650cc water to make it become liquid. Firstly, you can fill the big plastic plate with boiled water (100°C) and then put the small plastic plate with etchant inside on the surface of the hot water. The hot water is used to heat the etchant. The highest temperature the etchant can stand is 65°C. Although the temperature of water is 100°C, the temperature transferred to the etchant will be just right since the heat dissipation capacity of water is strong enough and the area of water is large enough and the heat is transferred by plastic.

Then you may put the board in the etchant. Shake it to make the etching fast. The PCB making is done when the copper is milled off.

Actually, the etchant can be used for many PCBs, and we recommend you recycle the rest etchant for next use. When the etchant is less than 650cc, you may add water but make sure the total volume is within 650cc.

When the etchant loses its efficacy, you should consider doing revivification. Efficacy can be determined when the etchant's color turns dark blue and there are no bubbles being generated with PCB in it. A kind of waste liquor recovery agent can be used for revivification. First, water should be added to the agent to make it dissolved. Then the etchant and the agent is mixed and stirred and some blue sediment will appear. Next, some water should be added. After 24 hours, the blue sediment will subside. We can collect the blue sediment and throw it in the dustbin. In spite of the complexity of this process, it's perfectly worthwhile. NEVER pour the etchant directly in the sewer. Let's play our part protecting the environment.