Industry: Medical & Life Science Instrument

Company: Confidential

Services: PCB Prototype, PCB Fabrication, Turnkey Assembly

Background

Medical and life-science electronics demand unwavering reliability, strict compliance, and repeatable quality across batches. PCBCart meets that bar through standardized materials, controlled process windows, rigorous inspection (IPC Class 3), and audit-ready documentation—turning design intent into scalable, dependable production. Below, two typical boards from laboratory automation and fluidics control illustrate our approach.

Application Context (Customer Details Generalized)

The projects involve long-duty laboratory automation and precision fluidics control. Requirements emphasize:

Halogen-free laminates with high Tg for thermal stability

UL 94V-0 flammability compliance

ENIG surface finish with uniformity control

Solder mask via fill for high-density reliability

IPC Class 3 acceptance

Clear UL and lead-free markings plus date/production codes for traceability

Technical Specifications (Representative Medical Boards)

PCBCart aligns a unified manufacturing window to these parameters, ensuring consistent appearance and electrical performance from prototype to volume.

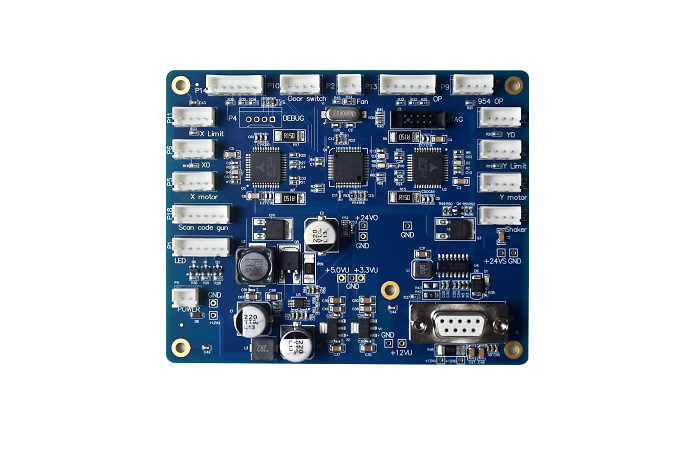

Board A

| Parameter | Specification |

| Substrate | TU862 HF (standard), halogen-free |

| Flammability | 94V-0 |

| TG | 170°C |

| Finished Thickness | 1.6 mm |

| Layers | 4 |

| Finished Copper | 1 oz |

| Surface Finish | ENIG |

| Via Processing | Solder mask via fill |

| Solder Mask | Blue |

| Silkscreen | White |

| Min Trace/Space | ≥ 4 mil |

| Min Hole Size | ≥ 0.254 mm |

| Board Size | 117 × 95 mm |

| Lead-Free Markings | Yes |

| UL + Logo | Yes |

| Date/Production Code | Yes |

| Acceptance | IPC Class 3 |

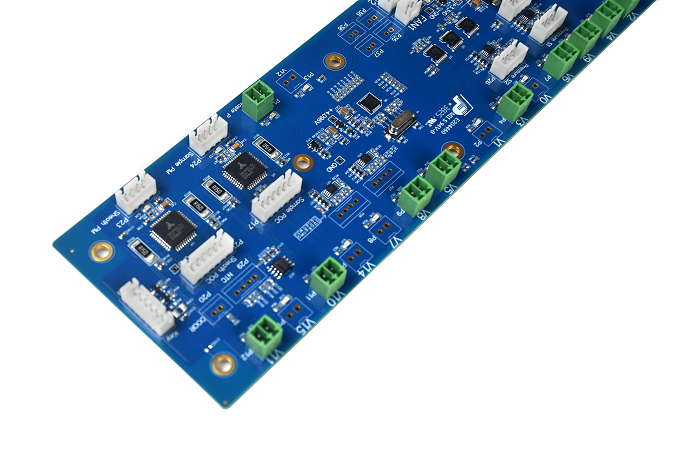

Board B

| Parameter | Specification |

| Substrate | TU862 HF (standard), halogen-free |

| Flammability | 94V-0 |

| TG | 170°C |

| Finished Thickness | 2.0 mm |

| Finished Copper | 1 oz |

| Surface Finish | ENIG |

| Via Processing | Solder mask via fill |

| Solder Mask | Blue |

| Silkscreen | White |

| Min Trace/Space | ≥ 4 mil |

| Min Hole Size | ≥ 0.254 mm |

| Board Size | 258 × 78 mm |

| Panelization | No |

| Lead-Free Markings | Yes |

| UL + Logo | Yes |

| Date/Production Code | Yes |

| Acceptance | IPC Class 3 |

Customer Testimonial

"Our instruments are durable under continuous use. PCBCart delivers clean, reliable builds with excellent ENIG flatness, solid via fills, and thorough inspections. Their DFM feedback accelerates prototyping and simplifies scaling, meeting the rigorous standards required for medical products."

Core Advantages of PCBCart's Medical PCBA Services

PCBCart excels in delivering precise, reliable, and compliant PCBA solutions tailored for the medical industry. Our broad assembly capabilities and stringent quality controls ensure consistent performance across all projects.

Advanced Materials and Compliance: We select high Tg halogen-free laminates for thermal stability, meeting UL 94V-0 flammability standards for safety in medical applications.

Superior Surface Finishes: Our ENIG surface finishes are meticulously controlled for uniformity, ensuring excellent solderability and corrosion resistance.

High-Density Reliability: Implementing solder mask via fills enhances reliability in dense circuit areas, reducing risks of defects and ensuring robust connections.

Precision in Manufacturing: With capabilities including SMT and THT, we support complex and high-density board designs, delivering on precision and reliability.

Rigorous Quality Assurance: Adhering to IPC Class 3 standards, we conduct thorough inspections for quality assurance across all production stages.

Comprehensive Traceability and Records: Clear UL and lead-free markings, along with detailed date/production codes, ensure full traceability and audit readiness, supported by complete batch records.

PCBCart Medical Assembly: Reliable by Design, Scalable in Practice

Designed for clinical reliability and cost-effectiveness, PCBCart integrates PCB fabrication, component sourcing, and assembly under strict medical standards. With IPC Class 3 inspections, high-Tg halogen-free laminates, precise ENIG finishing, and verified via-fills, we ensure consistent performance from prototypes to full-scale production. Our standardized materials and processes, with full traceability, shorten lead times, lower costs, and keep production audit-ready. Since 2005, we've supported thousands of medical and life-science projects, helping teams launch reliable instruments quickly. Ready with a design? Explore PCBCart’s medical assembly services and request a free quote today.