Industry: Industrial Automation

Company: Confidential

Ordered Service: PCB Prototype, PCB Fabrication, Turnkey Assembly

Background

At PCBCart, we believe the best projects become the best partnerships.

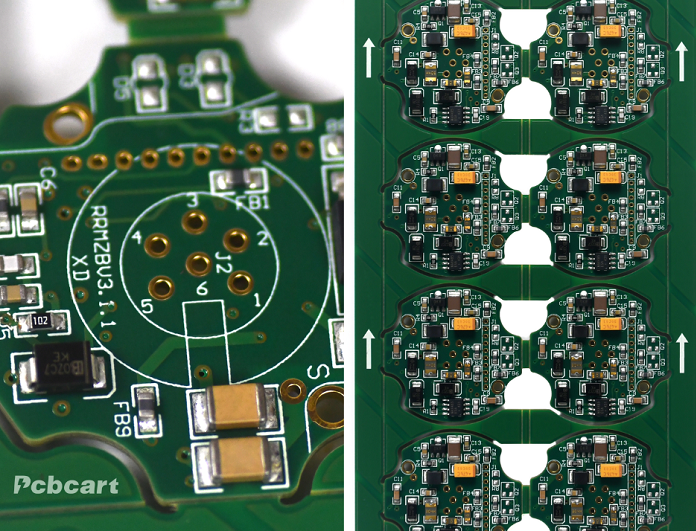

Recently, a leading company in the Intelligent Manufacturing sector presented us with a critical challenge. They required high-end PCBA services for sensitive industrial inspection equipment.

"Good enough" was not an option—precision was essential.

After thoroughly understanding their specific needs, we delivered the following professional services: Extreme-precision assembly, Rigorous quality control, and Handling of high-complexity components.

Our commitment not only addressed their critical challenge but also established the foundation for a long-term, trusted partnership. We are honored to be their partner in innovation.

The PCBCart Assembly Solution: Specialized Execution

Technique and Parameter Requirements

PCBCart executed an integrated program from DFM-backed prototyping to volume production, maximizing yield and minimizing cost.

DFM Collaboration

Panel utilization optimized to reduce total cost per unit

Clearance, annular ring, and via-to-copper tuning to improve yield

Fiducials and stencil aperture refinements for consistent paste deposition

The Specs That Matter

| Parameter | Specification |

| Industry | Industrial Sector |

| Board size | 204mm × 94mm |

| Layer count | 4 layers at 1.6mm thickness |

| Material | FR4 TG155 |

| Surface finish | ENIG |

| Quality standard | IPC Class 2 |

Turnkey SMT Assembly

Controlled reflow profiles validated for ENIG and board mass

Laser-cut stainless-steel stencil with selective reductions to mitigate tombstoning and voiding

Component procurement with lifecycle checks and vetted alternates to avoid supply disruptions

AOI on fine-pitch and critical nets; sample X-ray for hidden joints when applicable

Lot-level material and process traceability

Results: A Trusted, Long-Term Alliance

The industrial company’s products deliver exceptional performance and strong customer acclaim.

While market expansion is hard to measure directly, the steady growth in PCBCart’s order volume and the rising complexity of projects demonstrate ongoing demand.

This trust is built on actionable results:

High first-pass yields from prototype through production

Zero field failures related to PCB quality in the first year

30% cost reduction compared to their previous supplier

Quick Delivery: Smooth transition from prototype to production with predictable lead times

Customer Testimonial

“PCBCart delivered exactly what our industrial controller program needed—robust build quality, clean assembly, and dependable supply at a competitive cost. Their DFM guidance and turnkey execution shortened our path from prototype to production.”

PCBCart: Built for Reliability, Priced for Reality

Looking for reliable PCBs and PCBAs that fit your budget? PCBCart offers high‑reliability boards with scalable costs, from prototype to volume, making us a trusted manufacturing partner for real products.

We provide a true one-stop service, including PCB fabrication, component sourcing, and SMT/THT assembly. This unifies processes, reducing lead times and lowering total cost.

Since 2005, we’ve focused on consistent quality, fast turnaround, and smart cost control.

Thousands of enterprises trust PCBCart to deliver production‑ready builds and accelerate time‑to‑market. Have a design ready? Explore our turnkey PCB assembly and request a FREE quote today.