It's estimated that over half electronic components fail due to high stress resulting from thermal environment. Recent years has witnessed wide devices of large-scale and hyper-scale integrated circuits (ICs) and surface mount technology (SMT) and electronic products start embracing development directions towards miniaturization, high density and high reliability. Accordingly, electronic systems are calling for increasingly higher requirement of thermal performance. After all, born with the advent of electronic products, thermal management plays a critical role in determining the performance and functions of electronic systems.

As backbone of electronic devices, rational design of PCBs (Printed Circuit Boards) ensures their high performance. If PCB design partially or even totally fails to meet thermal requirement, electronic devices will definitely suffer from damage risk or even failure. Constantly growing integrity of circuit modules and massive applications of ICs and multi-chip module (MCM) contribute to the improvement of component assembly density which thereafter leads to higher density of heat flow on PCBs. High-quality PCBs not only derive from accurate and rational layout and routing, but also rely on high thermal reliability for secure operation. Therefore, it's of much significance to implement comprehensive thermal dissipation rules and analysis on PCBs. This article begins with start-up thermal design principles and introduces engineer-friendly thermal design rules for handy application by electronics designers for their job.

Basic Principles of Thermal Design

Thermal design is based on the basic theory of heat transfer and fluid mechanics. Where there's temperature difference, there's heat transfer from high temperature zone to low temperature zone. Heat transfer can be achieved through heat conduction, heat convection and heat radiation.

The formula of heat transfer is displayed as: φ=KAΔt, in which φ stands for the amount of heat transmission whose unit is W, K stands for the coefficient of heat transmission whose unit is W/(m2 x K), A stands for the area of heat transmission whose unit is m2 and Δt stands for the temperature difference between thermal fluid and cold fluid whose unit is K.

Thermal design of PCBs is defined as the process in which the thermal resistance from heat source to heat consumption space is decreased to minimum through cooling measures by thermal transmission attributes or density of heat fluid is controlled to be within an acceptable range. In order to ensure its reliability, valid thermal design measures must be taken from the following perspectives, including:

a. Natural cooling, which conducts heat without external strength. It includes heat conduction, radiation heat transfer and natural convection transfer.

b. Forced air cooling. It makes cooling air flow through electronic devices or components, transferring heat from heat source to heat sink through ventilator or ram air.

c. Fluid cooling. There are two methods of fluid cooling:

1). Direct fluid cooling refers to the process during which components are directly soaked into the fluid coolant.

2). Indirect fluid cooling refers to the process during which components are not directly in touch with fluid coolant. However, cooling is carried out through heat exchanger or cold plate.

d. Evaporation cooling. Currently, it's the most effective heat conduction method. Thermal transmission is obtained by ebullition of cooling medium.

e. Other types of cooling measures: thermotube, cold plate, thermoelectric refrigeration.

In the process of thermal management, proper thermal design measures can be made according to practical conditions such as the practical operation environment (temperature, humidity, atmospheric pressure, dust etc.), thermal fluid density on board, power volume density and total power consumption, surface area, volume, heat sink and other special conditions, in order to ensure the even distribution of temperature and reasonable temperature rise within regulated limited value.

Thermal Design Rules

General purpose of thermal design is to control the temperature of all the electronic components assembled on circuit boards inside electronic products, to ensure the stability of electrical performance, to avoid or reduce temperature drift of electrical parameters, to decrease the basic failure rate of components, and to make the temperature in the operation environment not go beyond maximum allowable temperature. This article depicts PCB thermal design rules in 3 perspectives: the utilization of components on PCBs, thermal design of PCBs, components assembly and PCB layout.

a. Utilization of Electronic Components

1). How to control working temperature of components?

Temperature is the first element affecting component performance and failure rate. The highest allowable working temperature and power consumption should be determined according to required level of reliability and the distributed failure rate of each component. Table 1 shows the values of allowable maximum surface temperature of components from the perspective of reliability in thermal design.

|

Components

|

Max. Surface

Temp/°C

|

Components

|

Max. Surface

Temp/°C

|

|

Transformer, choke

|

95

|

Ceramic capacitor

|

80-85

|

|

Metal film resistor

|

100

|

Glass ceramic capacitor

|

200

|

|

Carbon-film resistor

|

120

|

Silicon transistor

|

150-200

|

|

Palladium-film resistor

|

200

|

Germanium transistor

|

70-90

|

|

Pressed wire wound resistor

|

150

|

Vacuum tube

|

15-200

|

|

Printed resistor

|

85

|

CMOS fully sealed flat package

|

125

|

|

Painting wire wound resistor

|

225

|

Ceramic DIP, black porcelain DIP

|

/

|

|

Paper capacitor

|

75-85

|

CMOS plastic DIP

|

85

|

|

Film capacitor

|

60-130

|

TTL small-scale IC

|

25-125

|

|

Mica capacitor

|

70-120

|

TTL middle-scale IC

|

70-85

|

2). How to control component junction temperature?

Component junction temperature depends on its own power consumption, thermal resistance and environment temperature. Thus, measures of controlling junction temperature within an allowable range include:

• Components with low internal thermal resistance are picked up.

• Derating is used to decrease the temperature rising.

• Circuits, especially those containing power components, should depend on elaborate thermal design for reliability with guidelines depicted in standard manual conformed to.

3). How to design derating when components are used?

Based on needs, derating design can be implemented in practical usage in order to make components perform in the condition of below rated parameter (power, voltage, current) so that temperature rising and failure rate will be dramatically reduced.

b. Thermal Design Rules of PCBs

The vertical assembly of PCBs is beneficial for heat dissipation and the distance between boards should be maintained at least 20mm. Board thermal design rules include:

1). Material with ability of anti high temperature and high conduction parameter is picked up as substrate material of PCBs. When it comes to circuits with high power and density, aluminum base and ceramic can be used as substrate material owing to their low thermal resistance (PCBCart is fully capable of manufacturing PCBs with those substrate materials. You may send your PCB files along with quantity requirement on this page for Aluminum based and Ceramic based PCBs quotation).

2). Multi-layer structure is an optimal choice for PCB thermal dissipation.

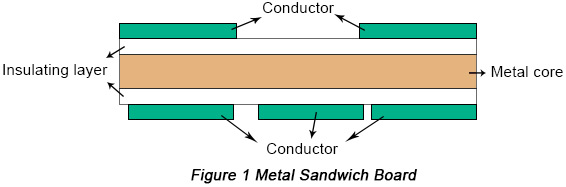

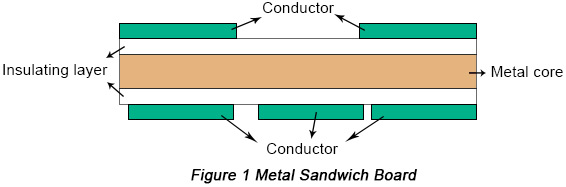

3). To improve heat conduction ability of circuit boards, it's best to use boards dissipating heat. Metal-core board can be applied in multi-layer PCBs to obtain excellent heat dissipation between board, supporting devices and heat dissipating devices. Protective coating and encapsulating material can be used if necessary to accelerate thermal transmission to supporting devices or heat dissipating devices.

4). In order to increase heat dissipation ability of PCBs, a busbar can be used, which can be regarded as an excellent radiator and is capable of increasing anti-interference performance of PCBs.

5). To improve thermal dissipation ability of PCBs, thickness of metal foil should be increased, and inner conductor should use metal foil with large area. What's more, width of ground lines should be properly increased because ground lines with big area are both capable of increasing anti-interference ability and dissipating heat capacity.

c. Components Assembly and PCB Layout

Component layout is quite essential to thermal performance of PCBs, especially those that are vertically placed. Component assembly direction should conform to flow characteristics of coolant to provide coolant with the least resistance. The rules applying to components in terms of assembly and layout include:

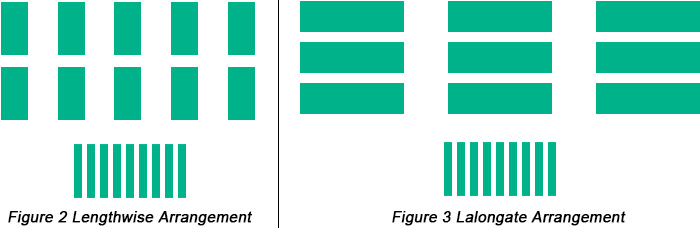

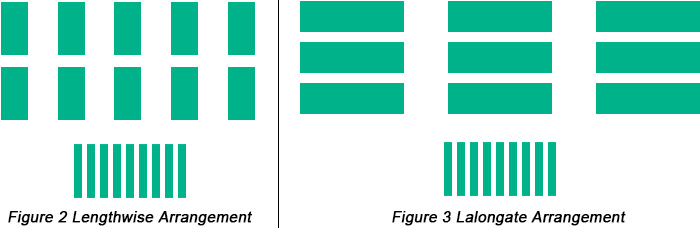

1). For the products with free convection air cooling method, it's best to arrange ICs or other components in lengthwise arrangement as the example displayed in Figure 2 below. For the products with forced air cooling method, it's best to arrange ICs or other components in lalongate arrangement as the example displayed in Figure 3 below.

2). The components on the same PCB should be classified and placed according to their heat productivity and heat dissipation level. Components with low heat productivity or low heat resistance (small signal transistor, small-scale IC, electrolytic capacitor, etc.) should be placed at upstream (entrance) while components with high heat productivity or high heat resistance (frequency transistor, hyper-scale IC, etc.) should be placed at downstream. At the periphery of small-signal amplifiers should be placed components with small temperature drift and liquid medium capacitors should be far away from heat source.

3). On the horizontal direction, components with high frequency should be arranged adjacent to the edge of PCBs in order to minimize heat transmission path. On the vertical direction, components with high frequency should be arranged close to the upper part of PCBs in order to decrease their influence to the temperature of other components.

4). Components that are sensitive to temperature should be arranged at the area with the lowest temperature such as the bottom of a product. They mustn't be placed right above components generating heat and they should be placed far from components generating heat or be isolated from them.

5). Components with the most power consumption and heat generation should be arranged adjacent to the best place for heat dissipation. Never arrange components with high temperature at the corner or edge unless radiators are arranged around them. When arranging power resistors, relatively large components should be picked up and sufficient heat dissipation space should be left for them in the process of PCB layout.

6). Power should be distributed evenly on PCBs to maintain balance and conformity and avoid concentration of heat points. It's difficult to reach strict uniformity but areas with extremely high power must be avoided in case over-heated points will break the normal operation of the whole circuit.

7). In the process of PCB design, air flow path must be taken into full consideration and components must be reasonably arranged. Air tends to flow towards the place with little resistance so relatively big airspace should be avoided when arranging components on PCBs.

8). Thermal assembly technology should be applied on circuit boards to achieve relatively good heat transmission effect. Over half of the heat generated by components such as ICs and microprocessors is transmitted to PCBs through their own leads whose assembly holes should use metal-plating holes. These components can also be directly mounted on thermal conduction stick or board to reduce thermal resistance caused by components.

9). Thermal resistance should be decreased as much as possible in the connections between components with high heat dissipation and PCBs. In order to meet the requirement of heat attributes, some heat conduction materials can be used under the chip and the heat dissipation of components in the contact area should be maintained.

10). Pins of components should be shortened in the connection of components and PCBs. When selecting components with high power consumption, conductivity of lead material should be considered. If possible, choose components whose leads have larger cross section and that have the most pins.

d. Other Requirement

1). Component Package: component package type and heat conduction rate should be considered in PCB thermal design. Heat conduction path can be provided between substrate and component package and air break should be avoided on heat conduction path.

2). Technique Method: local high temperature can be caused in the areas with components on both sides of the board. In order to change heat dissipation condition, some fine copper can be added in the soldering paste so that the solder points will rise to a certain height under components. Airspace is increased between components and PCB so that thermal convection can be improved.

3). Heat Dissipation Holes: some heat dissipation holes and blind holes can be arranged on PCBs so that heat dissipation area can be effectively increased, thermal resistance can be decreased and power density of PCBs can be increased.

Thermal Analysis

Based on computational heat transfer, thermal analysis whose numerical computation methods mainly include finite difference method, finite element method and boundary element method, referring to the process of simplifying modules, establishing math modules, solving non-linear equation, making and adjusting analytical procedure and computation, measurement and test of thermal parameters.

As a fundamental aspect of thermal design, thermal analysis is an important method of evaluating the importance of thermal design. PCB thermal analysis refers to the process of establishing the thermal module of components and set simulation control parameters according to the structure and raw material of PCBs, package type of components and PCB operating environment to estimate values of thermal behaviors of PCBs. Thermal analysis must be carried out in the concept phase before layout and throughout the whole process of PCB design.

Values of component temperature, board temperature and airflow temperature can be obtained from thermal analysis, displaying the thermal attributes of PCBs in the form of colored pictures, temperature isotherm visual graphics or specific data.

Based on the result of thermal analysis, thermal problems of PCB can be found out quickly and timely measures can be properly taken and high temperature dense areas can be eliminated, which will determine the heat conduction path, optimize the positions of key components, the shape of radiator and size to fully take advantage of heat dissipation rate, increase heat transmission efficiency of heat dissipation holes and radiators and determine the space between boards and components on boards.

PCCBart has Rich Experience in Manufacturing PCBs with Advanced Features

The thermal control must be optimized to meet the needs of the performance and reliability of current electronics with devices becoming smaller and more integrated. Effective PCB design with intelligent cooling techniques and component positioning are required so that devices will not overheat and electronic systems will be able to function longer. With sophisticated thermal design methods, engineers can offer reliable operation even under severe conditions of thermal stress, safeguarding devices against potential failure.

PCBCart, with years of experience in PCB manufacturing, specializes in creating high-performance circuit boards with excellent thermal management. With customers across the globe, we offer custom PCBs with cutting-edge cooling technology tailored to your specific needs. Our focus on quality and innovation ensures that your electronic products work reliably even in extreme conditions.

Request a Customized Quote for Your PCB Project with PCBCart

Helpful Resources

• PCB Thermal Design Considerations

• Internal Thermal Dissipation Design of PCB based on Thermal Model

• Metal Core PCB an Ideal Solution to Thermal Issues in PCB and PCBA

• How to Evaluate A PCB Manufacturer or A PCB Assembler

• Full Feature PCB Fabrication Service from PCBCart

• Advanced PCB Assembly Service from PCCBart