Printed Circuit Board (PCB) is a fundamental element of electronic components and PCB fabrication is a basic experiment skill for both electronics majors and electronics engineers. Although PCB board fabrication technology has developed sufficiently maturely, it's unrealistic and unnecessary to produce circuit boards conforming to specialized PCB manufacturing process if they just want to testify their designs because that's time-consuming and high-cost. Therefore, this article will provide an easy method to produce a double-side PCB so that electronics majors and engineers can have a better alternative.

PCB manufacturing primarily comes in two methods: chemical mode and physical mode. Nowadays, the most prevalent PCB fabrication methods high schools take advantage of are thermal transfer printing and physical engraving. The former belongs to chemical domain while the latter to physical domain.

• Thermal Transfer Printing

To carry out thermal transfer printing, first, an ordinary laser printer is used to print PCB image onto specialized thermal transfer paper. Then, PCB image that has been printed on thermal transfer paper is transferred on Copper Clad Laminate (CCL) through thermal transfer equipment. Finally, a high-precision PCB is produced after later processes including etching and PCB drilling. In high school labs, thermal transfer printing is leveraged to produce high-precision PCBs and can be achieved in one hour. When it comes to double-side PCB fabrication, the protruding issue lies in misalignment that hasn't been successfully solved with current manufacturing method used. As a result, double-side PCBs fabricated in thermal transfer printing method fail to optimally work on electronic products.

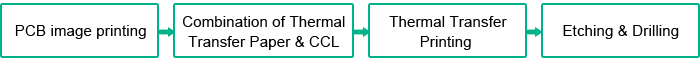

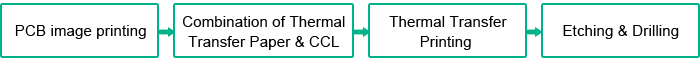

Thermal transfer printing sticks to the following PCB fabrication process:

1. Bottom PCB image is printed on a piece of thermal transfer paper by an ordinary laser printer.

2. Top PCB image is printed on another piece of thermal transfer paper by an ordinary laser printer.

3. Two pieces of thermal transfer paper are closely stuck to a well-cut double-side CCL. Clear tape can be used to fix the position of paper and plate to avoid misalignment.

4. Thermal transfer printing is carried out by putting CCL with thermal transfer paper stuck into thermal transfer printing equipment. A CCL with PCB image printed on is then obtained after cooling.

5. Etching and PCB drilling are then implemented.

The process can be summarized into the following figure:

Among all the phases of thermal transfer printing for PCB fabrication, application of Step 3 can accurately lead to alignment of two pieces of thermal transfer paper. When it comes to Step 4, however, misalignment tends to be caused in thermal transfer equipment. As a result, a double-side PCBs can be hardly successfully manufactured unless a couple of trials have been made.

• Physical Engraving

Based on basic principles of physical engraving, physical engraving conforms to milling principle with extra or unnecessary parts of CCL milled off. The applied equipment is actually a type of small CNC drilling and milling machine that is also called circuit board engraving machine. In the process of double-side PCB manufacturing, after one side is finished milling, board should be flipped over for milling on the other side of the board. The flipping process possibly leads to misalignment that should be corrected through software and hardware so that rejection rate of double-side PCBs will be reduced.

• Comparison between Thermal Transfer Printing and Physical Engraving

According to the comparison between the two methods, thermal transfer printing performs better than physical engraving in terms of the following aspects:

1. CNC drilling and milling machine features relatively high cost and takes up more lab space. Thermal transfer printing machine, however, features low cost and takes up less space than CNC drilling and milling machine.

2. A Double-side PCB can be completed within one hour when thermal transfer printing is used. In spite of possible misalignment calling for multiple times of thermal transfer printing, a double-side PCB can be fabricated within three hours at most. CNC drilling and milling machine, however, takes more time, at least four hours. Furthermore, CNC drilling and milling machine can deal with only one piece of PCB board simultaneously while thermal transfer printing is capable of producing multiple double-side PCBs within the same time period.

In order to solve misalignment issue that is protruding in traditional thermal transfer printing, this article will provide an improved thermal transfer printing method for PCB fabrication with the following steps.

1. Bottom PCB image and mirror top PCB image are printed onto the same thermal transfer paper and through holes of bottom PCB image and top PCB image are linearly symmetrical.

2. Thermal transfer paper is folded along symmetrical line and covered onto well-cut double-side CCL.

3. Double-side CCL with thermal transfer paper covered on is then put into thermal transfer printing equipment for thermal transfer printing. The folding part first enters thermal transfer printing equipment and a CCL with PCB image printed on can be obtained after cooling.

4. Etching and PCB drilling.

The above process can effectively defeat misalignment issue that always takes place in traditional thermal transfer printing for PCB fabrication by printing top and bottom PCB images on the same thermal transfer paper. As a result, a reliable double-side PCB can be smoothly fabricated all at once.

PCB image printing on the same piece of thermal transfer paper can be completed based on any PCB design software holding different operations. All in all, this improved thermal transfer printing method for PCB fabrication is the most effective one for electronics majors or engineers who can use to produce double-side PCBs in a lab.

At PCBCart, double-sided PCBs can be manufactured as quickly as 48 hours with FR4 material used. Apart from ordinary FR4 boards, other types of advanced PCBs can be also prototyped at PCBCart like Flex PCBs, Flex-Rigid PCBs, Aluminum PCBs etc. to be compatible with your unique needs. Got a project ready for prototyping? Click below button to get PCB Prototyping price now. New customers can save up to $200 off their first order!

Request Quickturn PCB Prototyping Price

Helpful Resources

• Full Feature PCB Manufacturing Service from PCBCart

• Advanced Turnkey PCB Assembly Service from PCBCart

• The Benefits of Choosing PCBCart as Your PCB Partner