In the vast landscape of modern technology, Printed Circuit Boards (PCBs) are the behind-the-scenes heroes, quietly powering devices that change our world. These quiet boards, yet invaluable, serve a pivotal role in enabling electronic components to work and talk. From the phone in your pocket to the satellites that orbit the earth, PCBs are the driving force behind innovation. In this article, the top 10 applications of PCBs and how they are mission-critical across industries are examined.

What are Printed Circuit Boards?

PCBs are flat, light pieces of insulating material such as fiberglass or epoxy, having thin insulating copper paths. These paths connect electronic components, including resistors, capacitors, and microchips, so that electricity can flow through them and the components function efficiently. PCBs are available in varying forms, from simple single-layer boards to complex multilayer structures, depending on their uses—ranging from simple remote controls to complex computer motherboards.

Types of PCB Assembly Processes

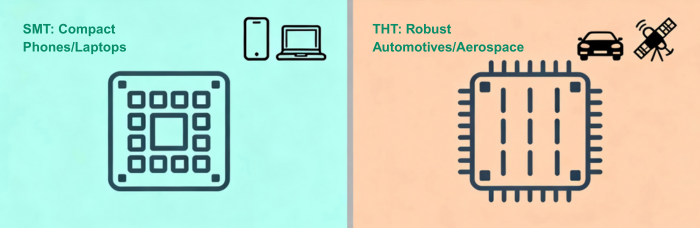

PCB assembly is tailored to the design and usage of the device they are used for. The two chief methods are Surface Mount Technology (SMT) and Through-Hole PCB Assembly:

Surface Mount Technology (SMT): SMT involves mounting components onto the surface of a PCB using no drilled holes. SMT is common in new electronic products such as smartphones, laptops, and wearables, making it possible to have compact, lightweight, and high-density designs. SMT allows high-speed production and automation and is thus ideal for mass production in consumer and industrial electronics.

Through-Hole PCB Assembly: This traditional method is when component leads are soldered into predrilled holes on the board. It forms solid mechanical bonds, and therefore it is best suited for applications that must be reliable and robust, such as automotive, industrial, and aerospace systems. Through-hole technology is better suited to endure harsh conditions than SMT.

Top 10 Applications for Printed Circuit Board Assemblies

Medical Devices

Accuracy and reliability are most crucial for medical devices, making PCBs a necessity. They are used in devices like MRI machines, pacemakers, and diagnostic devices, where accuracy is of the highest priority. Highly compact and highly reliable boards have a growing demand in the automotive industry, and PCBs play a key role in developing next-generation automotive technologies.

Consumer Electronics

PCBs are at the heart of consumer electronics, enabling the compact sizes and high functionality of smartwatches, tablets, and smartphones. Fabrication techniques like High-Density Interconnect (HDI) and multilayer PCBs allow more components to be compressed into decreasing spaces, driving innovation in personal devices.

LEDs

LED lighting solutions are founded upon PCBs for controlling brightness, power consumption, and heat transfer. Aluminum-backed PCBs are especially effective in terms of heat dissipation, ensuring performance and durability. LEDs are therefore ideally suited for applications in residential, commercial, and industrial lighting.

Industrial Equipment

In industrial uses, PCBs provide long-lasting performance for factory machinery and automation systems like robotics and control modules. They are designed to last in rugged conditions such as high heat, chemical exposure, and mechanical shock, therefore ensuring reliability and durability.

Automotive Electronics

Today's cars rely heavily on PCBs for the majority of their systems, including engine control units, audio and radio systems, and driver assistance systems. PCBs are exposed to the vibrations and temperature fluctuations of the automotive environment, requiring robust and resilient designs that offer safety and efficiency.

Telecommunication Systems

PCBs are indispensable in telecommunication facilities, supporting equipment like routers, satellites, and cell towers, which move data rapidly and support robust connections. Network advancement, particularly 5G, continues to place high-performance PCBs into focus to meet increasing data demands.

Aerospace and Defense

PCBs are crucial in aerospace and defense applications, powering navigation, communication, and control systems. They must operate in extreme environments, such as when in flight or in war. Some materials like light yet strong anodized aluminum are commonly used to endure the strains of aerospace activities.

Home Appliances

PCBs are used in home appliances such as refrigerators, washing machines, and microwaves to enable efficient operation and intelligent features. As home automation has evolved, PCBs contribute even more significantly to the delivery of energy-efficient and user-friendly solutions.

Wearable Technology

The miniaturization and portability of wearables such as fitness trackers and smart glasses are made possible due to PCBs in miniaturized form. The PCBs allow the necessary performance within small-sized form factors in line with existing miniaturization and mobility trends.

Renewable Energy Systems

Renewable energy equipment like solar panels and wind turbines employ PCBs to efficiently manage power generation and supply. They are the most important elements in such equipment to optimize the conversion and storage of energy, promoting green energy solutions.

Factors for PCB Selection in Different Applications

Choosing the right PCB for an application must be done with careful consideration of several important factors:

Size and Weight: Small devices need lightweight and compact PCBs.

Material Quality: Aerospace and medical industries require quality materials to deliver precision and consistency.

Cost: Performance versus cost is crucial, especially in consumer electronics and mass-produced goods.

Durability: Automotive and industrial applications require PCBs that can withstand tough conditions, necessitating heavy-duty construction.

Customization: Programmable PCBs cater to specific industry demands, providing specialized solutions for unique applications.

Printed Circuit Boards are the backbones of today's technology, in the middle of innovation in many sectors. From consumer technology to lifesaving medical equipment and cutting-edge aerospace systems, PCBs power the technology that is changing our world. With technology evolving, the demand for efficient, effective, and adaptive PCBs will increase.

Here at PCBCart, we offer higher-quality PCB assembly solutions to suit your unique needs. Whether you are making a prototype or mass production, our expertise ensures quality, precision, and rapid turnaround time. For reliable PCB solutions, contact us today and discover how we can help your next project.

Get an Instant Quote for High-Quality PCB Assembly

Helpful resources:

• Printed Circuit Board Terminology

• How to Choose the Right PCB Assembly Services?

• PCB Materials

• PCB Manufacturing Process — A Step-by-Step Guide

• Common Defects in PCB Assembly and How to Prevent Them