In the global competitive electronics manufacturing industry, the selection of an appropriate PCB assembly strategy is instrumental in deciding the performance, reliability, and efficiency of the product. A selection between Surface Mount Technology (SMT), Through-Hole Technology (THT), and hybrid assembly techniques can fundamentally influence the success of an electronic product.

The Importance of PCB Assembly Technology

PCB assembly is the critical task of mounting and soldering electronic parts onto a printed circuit board (PCB). This operation has a significant impact on the stability, performance, shape factor, and downstream assembly efficiency of the finished electronics product. As more complex product designs are created, PCB assembly has evolved from hand soldering to highly automated, precision-driven techniques. Surface Mount Technology (SMT), Through-Hole Technology (THT), and Hybrid Assembly are the most common technologies employed today.

PCB Assembly Methods

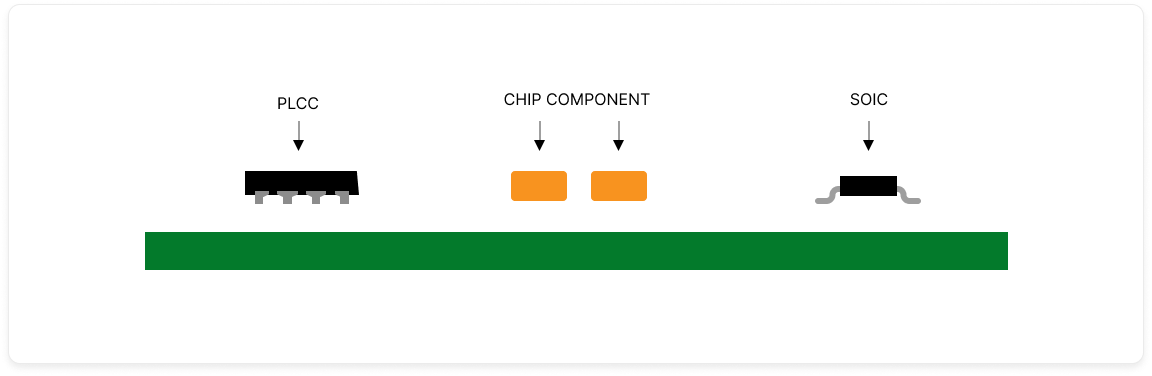

Surface Mount Technology (SMT)

SMT involves mounting and soldering surface-mounted devices (SMDs) on the surface of the PCB, without pre-drilled holes. SMT is the cornerstone of modern electronics production.

Key Features:

Direct surface mounting eliminates the need for drilling.

Supports high-speed, automatic pick-and-place and reflow soldering.

Supports miniaturization and higher throughput.

Suitable for advanced packages such as BGA, QFN, and LGA.

Applications:

Consumer devices like smartphones and wearables.

Automotive, medical, and communication devices needing high-density, high-speed, and high-frequency boards.

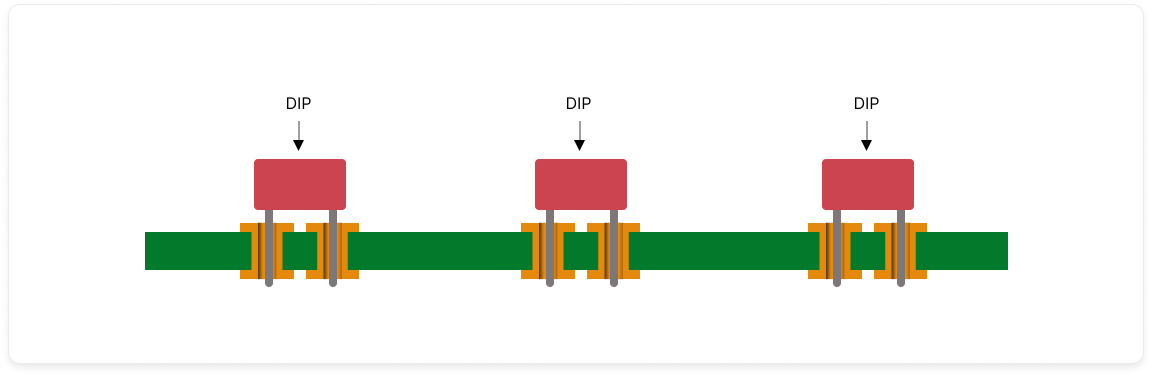

Through-Hole Technology (THT)

Components with leads are mounted into pre-drilled holes on the PCB and subsequently soldered through techniques like wave soldering or hand soldering.

Key Features:

Provides strong mechanical connections and high ruggedness.

Supports large or high-current components.

Lower automated, more suitable for small quantities or rugged products.

Applications:

Industrial control systems, power modules, and instrumentation.

Applications in high-vibration, high-temperature, or high-moisture environments.

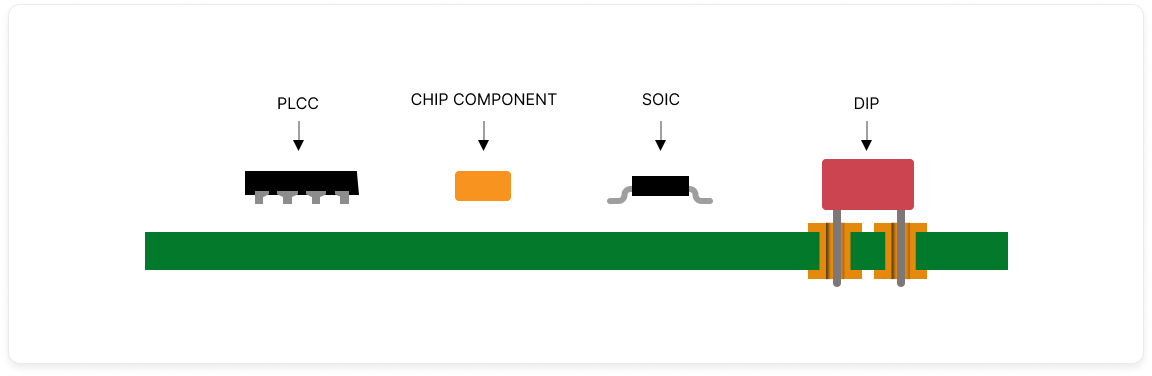

Hybrid Assembly

Hybrid assembly combines SMT and THT processes into a single PCB through the usage of the most beneficial aspects of both technologies to provide performance and reliability requirements.

Key Features:

Uses different component packages on a single board.

Utilizes maximum space and functional integration.

Needs advanced production lines and increased process control.

Applications:

IoT devices, communications equipment, and intelligent gateways.

Analog-digital mixed complex circuits or multi-power boards.

Selecting the Right Assembly Method

Package and Component Type

SMT is ideally suited to surface-mounted capacitors, ICs, and resistors, whereas leaded, bulky, or high-thermal devices predominantly require THT.

PCBs of different components highly benefit from hybrid assembly for improved layout and reliability.

Functional Needs and Environment of Operation

High-frequency, high-speed signal transmission is ideally suited to SMT.

Reliability in power handling as well as in vibration or heat environment is ensured by THT.

Hybrid systems have to utilize hybrid design areas for optimal performance.

Production Volume and Cost Issues

SMT offers mass production efficiency with lower per-unit costs.

THT is ideal for low-volume or specialty products with manual processes.

Hybrid assembly, although more expensive initially, offers better integration and reliability over the long term.

Future Trends: Integration and Smart Manufacturing

Greater Density and Smaller Component Sizes in SMT

SMT innovations include smaller packages, such as 01005 and micro BGA, that demand tighter placement and soldering accuracy.

The Permanent Place of THT

For use in fields like energy and infrastructure, THT can never be substituted for basic mechanical and electrical stability.

Higher Integration by Hybrid Assembly

Hybrid assembly enables integration in complex systems with better performance and layout optimization.

Automation and AI in Quality Control

Application of AOI and SPI systems alongside AI for predictive failure analysis is resulting in intelligent and responsive manufacturing processes.

Making the Right Choice

Understanding the various advantages, limitations, and conditions that apply to SMT and THT is essential in deciding the appropriate assembly method. The understanding that these processes are complementary and not competitive ensures product success. Integrating manufacturing concerns at the outset of R&D and using proven, multi-process assembly teams enhances product quality, minimizes iteration cycles, and accelerates time-to-market.

With precise use of hybrid assembly, PCBCart enables customers to achieve optimal results, combining cutting-edge efficiency with time-tested reliability in electronics manufacturing. From manufacturing IoT products and high-frequency circuits to fabricating heavy-duty power systems, PCBCart ensures that the assembly process meets product specifications, achieving success from design to deployment.

Get an Instant Quote for Advanced PCB Assembly

Helpful resources:

• SMT, Surface Mount Technology Assembly

• How to Make the Best of Through-Hole Technology (THT) in High-Speed PCB Design

• Comparison between Through-Hole Assembly (THA) and Surface Mount Assembly (SMA)

• Mixed Assembly Advantages

• How to Choose the Right PCB Assembly Services?