In the electronics manufacturing world, Printed Circuit Boards (PCBs) are of greatest importance. However, selecting components that will be used in a PCB can prove troublesome. While some components are widely available and therefore similar to others, others are specifically designed to suit custom projects, resulting in complexities of levels. Understanding what components are needed is of most importance so that there may be an easy assembly procedure. This article describes the most significant characteristics of PCB elements, offering understanding of their role in effective PCB assembly.

Understanding Printed Circuit Boards

PCBs are indispensable in the electronic equipment of today's times, acting as the backbone for connecting and mounting various electronic devices in order to construct useful circuits. A PCB is typically constructed from an insulating substrate, like fiberglass, covered with a thin conductivity, like copper, on one or both sides. The conducting coating is very thinly patterned to form paths, known as traces, through which electric signals may travel between components without interference. Soldering of components such as resistors, capacitors, and integrated circuits onto the PCB results in a functional circuit. The copper traces link all of these components, and thus the device can work as desired.

A good PCB is made up of a number of crucial components:

Substrate: The framework of the board, structural integrity.

Copper Layer: Enables electrical connection between components.

Solder Mask: Prevents copper traces from environmental deterioration and involuntary short circuits.

Silkscreen: Facilitates by marking for identification.

Benefits of PCB Components in Electronic Devices

Application of PCBs in electronics offers many key advantages:

Miniaturization: PCBs enable miniaturization of the circuit, resulting in compact and portable electronics.

Reliability: The structured format avoids loose contacts or short circuits, thereby enhancing reliability and lifespan as well.

Efficiency: PCBs create accurate routes for electrical signals, minimizing signal loss and interference.

Cost-Effectiveness: Large-scale production of PCB components makes them an inexpensive method for manufacturing electronics.

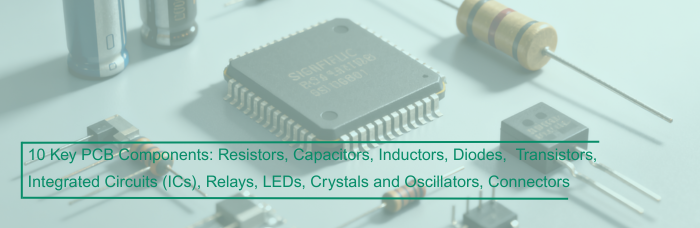

10 Basic PCB Components and What They Do

The following are the fundamental components you'll be seeing time and again on PCBs, along with their respective functions:

Resistors

With a critical role in constraining and directing the flow of current, resistors help regulate voltage levels and signal strength in a circuit, which is critical regarding maintaining functionality and safety.

Capacitors

Capable of holding and discharging energy, capacitors play vital roles in signal filtering, power supply regulation, and voltage smoothing in electronic circuits.

Inductors

Inductors inhibit electrical current fluctuations and are prevalent in energy storage and filtering applications, critical in devices like transformers and speakers.

Diodes

As one-way electrical highways, diodes restrict the flow of current in certain directions. They are crucial in the conversion process of alternating current (AC) to direct current (DC) and signal fidelity control.

Transistors

Miniature amplifiers and switches, transistors control electric flow within circuits and are vital to the operation of all electronic devices.

Integrated Circuits (ICs)

Places numerous components into an integrated package for advanced processing tasks—from mere logic functions to acting as microprocessors within computers.

Relays

Relays utilize electromagnetism to turn a circuit on or off, enabling control of high-power devices with no direct electrical interface.

LEDs

Light Emitting Diodes provide visible indicators and are being increasingly utilized for lighting applications due to being efficient and possessing a long lifespan.

These elements produce stable clock signals needed in order to synchronize operations in many digital devices.

Connectors

They provide interfaces for mounting of the PCB to external devices or auxiliary boards with the purpose of enabling smooth component interaction.

Connecting Components on a PCB

Components on a PCB are connected together using copper traces, which serve in much the same fashion as a city's road system, directing the electricity flow based upon the schematic layout. This can be achieved through surface-mount processes or through-hole manufacturing, depending on design need.

Evolution and Future Trends in PCB Design

With improving technology, PCBs are being designed ever smaller and more efficient to meet the requirement of miniaturized and efficient electronic products. This drive spurs the design of smaller and more intricate PCBs. There is also growing concern for the use of environmentally friendly materials and manufacturing processes in the industry, demonstrating commitment to sustainable development.

Selecting Proper Components

Choosing the right components for your PCB is very important. Design points to consider should include aspects such as component size, functionality, and compatibility with other parts on the board. Careful planning when choosing the components not only makes assembly easier but also helps the device to perform at its best.

By taking the time to learn about the different types of PCB components and their applications, you're better prepared to deal with the complexities of designing and building circuits boards. This enables you to create dependable, efficient, and inexpensive electronic solutions, setting your projects on a course for success in a fast-evolving world of technology.

PCBCart is a master at providing quality PCB assembly services, combining precision with expert expertise to ensure all parts function at optimum levels. From design to production, our services span across industries comprehensively, providing reliability and performance. We strive to help you turn your electronic innovations into realities efficiently and effectively. Contact us to find out how you can accomplish your design dreams.

Understanding the unique roles of PCB pieces is vital to anyone working with electronics. Being aware of how each item helps allows for improved design, easier troubleshooting, and more efficient layouts, leading to the best performance of your PCBs.

Get an Instant Quote for Cost-Effective & Advanced Assembly Solutions

Helpful resources:

• Design Requirement of SMT PCBs Part Three: Component Layout Design

• PCB Assembly Inspection Methods